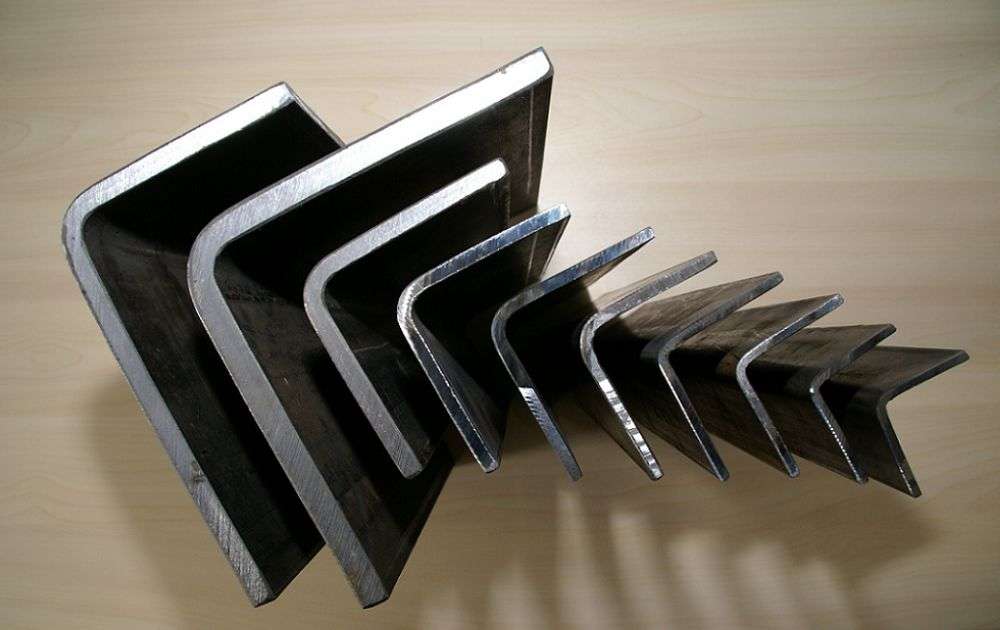

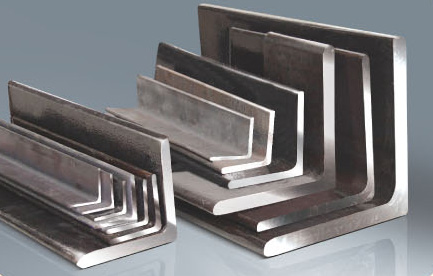

Angle Steel for Ship, Vessels and Other Steel Structures Building ASTM A276

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1)Standard:JIS AISI ASTM GB

2)Size: 25x25x3-100x100x10

3)Specification: as customers' requests.

Type | Stainless Steel Angle Bar |

Grade | AISI/SUS 201 202 301 302 303 304 304L 310 321 316 316L 410 420 430 |

Surface | Pickling, Sand Blasting |

Size | 25x25x3-100x100x10 |

Finished | Hot Rolled, Pickled, Sand Blasted |

Packing | Standard export packing, or as per customer's requests |

Payment | T/T, L/C, etc. |

Trade Terms | FOB/CFR/CIFetc. |

Stainless Steel Bar:

1.SS Angle Bar

*SS Equilateral Angle Bar

Specification:

Length: Standard length is 4m, 5m, 6m, length tolerance≤+ 40mm/pcs.

Shape: right angle tolerance is 2°

Surface: pickled or sand blasting.

2.SS Square Bar

*SS Cold Drawn Square Bar

*SS Hot Rolled & Pickled Square Bar

Specification:

Size: 12-180mm

Length:1-6mm

Surface: pickled&brushed

3.SS Hexagon Bar

*SS Cold Drawn Hexagon Bar

*SS Hot Rolled Hexagon Bar

Specification:

Diameter: 1.0-250mm

Length:1-6mm

Surface: bright

4.SS Flat Bar

*SS Hot Rolled & Pickled Flat Bar

*SS Drawn Flat Bar

Specification:

Thickness: from 3mm to 20mm

Width: from 19mm to 200mm

Length: 1-6Mm

Surface: pickled&brushed

OUR ADVANTAGES:

Our company is high quality supplier in China(mainland) with good reputation.

To develop the foreign markets, we provide customers high-quality stainless steel products with a competitive price, thoughtful after-sale service, excellent experience and import-export business skill.

Any questions, please feel free to contact with me!

- Q: Can steel angles be used for signage or billboards?

- Yes, steel angles can be used for signage or billboards. Steel angles are versatile and durable, making them suitable for various applications, including signage and billboards. They provide structural support and stability, ensuring that the signage or billboard remains securely in place. Additionally, steel angles can be easily customized and fabricated to meet specific design requirements. They can be painted or coated to enhance their appearance and protect against corrosion, ensuring longevity and durability for outdoor installations. Overall, steel angles are a reliable and practical choice for signage and billboards.

- Q: How are steel angles defined?

- Steel angles are defined based on the length of their legs, thickness, and their shape, which is typically L-shaped. These angles are commonly used in construction and engineering applications for structural support and framing purposes.

- Q: Are steel angles available in different grades?

- Different grades of steel angles are indeed available. Carbon steel is the commonly used material for steel angles, and it comes in various grades like A36, A572, and A588. These grades possess distinct chemical compositions and mechanical properties, rendering them suitable for diverse applications. Furthermore, stainless steel angles are also obtainable in grades such as 304 and 316, which exhibit exceptional corrosion resistance characteristics. Selecting the appropriate grade of steel angle depends on specific project requirements, encompassing strength, longevity, and resistance to corrosion.

- Q: Can steel angles be used as decorative elements?

- Certainly, steel angles have the potential to serve as delightful decorative elements. Steel angles, also referred to as L-shaped metal profiles, possess the ability to introduce an industrial or contemporary aesthetic to any given area. They possess a multitude of applications that can elevate the overall design and appearance of a room or outdoor space. One commonly employed application of steel angles as decorative elements is in the realm of architectural and interior design. These angles can be utilized as trim or edging on walls, ceilings, or furniture, thereby bestowing a distinct and fashionable appearance. Moreover, they can be employed to craft captivating patterns or designs on surfaces, such as herringbone or chevron patterns, which add visual allure and a contemporary ambiance. Furthermore, steel angles can be employed as decorative supports or brackets for shelves, countertops, or other fixtures. In addition to providing structural support, these angles contribute a modern and industrial touch to the overall design concept. By painting or powder-coating steel angles in various colors, they can be further enhanced to match the desired aesthetic, thereby augmenting their decorative appeal. Additionally, steel angles can also be employed as decorative elements in outdoor spaces. They can be incorporated into fences, gates, or railings, offering a durable and stylish solution. In the realm of landscaping, steel angles can be employed as decorative accents, such as creating borders or delineating flower beds, thereby introducing a contemporary design approach to the outdoor environment. In summary, steel angles present a versatile and visually appealing option for incorporating decorative elements into a wide range of design projects. Their sleek and industrial appearance, coupled with their strength and durability, render them a popular choice for both interior and exterior decorative purposes.

- Q: Can steel angles be used in mezzanine or raised platform constructions?

- Mezzanine or raised platform constructions can incorporate steel angles, which are flexible structural elements capable of providing support and stability in construction projects. Due to their strength and ability to bear heavy loads, steel angles are frequently utilized as framing members in mezzanine or raised platform structures. Their connection to other steel components like beams and columns is effortless, enabling the creation of a robust framework for the mezzanine or raised platform. Moreover, steel angles can serve as bracing and reinforcement elements, thereby enhancing the structure's overall stability and safety. In summary, steel angles are a commonly chosen option for mezzanine or raised platform constructions due to their durability, versatility, and cost-effectiveness.

- Q: How do steel angles perform under extreme temperatures?

- Steel angles typically perform well under extreme temperatures. Steel is known for its high thermal conductivity, which means it can quickly absorb and distribute heat. This property helps steel angles to withstand extreme temperatures without significant deformation or failure. However, it is important to note that the specific performance of steel angles under extreme temperatures can vary depending on factors such as the alloy composition and heat treatment of the steel. In some cases, steel angles may experience reduced strength or become more susceptible to corrosion at extremely high temperatures. It is recommended to consult with a materials engineer or refer to the manufacturer's specifications to determine the specific performance of steel angles under the desired extreme temperature conditions.

- Q: Can steel angles be used in the construction of hospitals?

- Steel angles are indeed suitable for use in the construction of hospitals. They are commonly employed in construction projects due to their ability to provide structural support and stability. When it comes to constructing hospitals, steel angles have a wide range of applications. They can be used for framing, support beams, trusses, and reinforcing walls and floors. Steel angles are renowned for their strength, durability, and fire resistance, which makes them ideal for meeting the demanding safety requirements of hospital buildings. Moreover, steel angles can be easily fabricated and manipulated to meet the specific design and structural needs of a hospital, allowing for flexibility in the construction process. All in all, steel angles are a dependable and versatile material that can be effectively utilized in hospital construction.

- Q: How do you reinforce a steel angle for added strength?

- There are various ways to reinforce a steel angle for added strength. One effective technique involves welding additional steel plates or gussets to the flanges of the angle. These plates or gussets are typically placed perpendicular to the angle and welded along their edges to create a stronger connection. This helps distribute the load and improve the structural integrity of the angle. Another approach is to create a sandwich-like structure by bolting or riveting additional steel plates or angles to the existing one. These additional elements can be positioned on either side or even on top of the existing angle, depending on the specific requirements. Bolting or riveting them together ensures a secure connection and enhances the overall strength of the angle. Furthermore, bracing techniques can also be employed to reinforce a steel angle. This involves adding diagonal steel members, commonly known as braces, to the angle. The braces are typically attached to the angle at multiple points using welding or bolting methods. By doing so, these braces help redistribute the forces acting on the angle and prevent excessive deflection or bending, thereby increasing its strength. It's important to consider factors such as the load or force the angle will experience, the desired level of strength, and the available resources when choosing a specific reinforcement method. Seeking guidance from a structural engineer or a professional in the field is highly recommended to ensure the appropriate reinforcement technique is chosen and implemented correctly.

- Q: How do steel angles contribute to the energy efficiency of a building?

- Steel angles can contribute to the energy efficiency of a building by providing structural support and reducing thermal bridging. They can be used to create a strong frame, which allows for larger windows and better natural lighting, reducing the need for artificial lighting during the day. Additionally, steel angles can be used as a barrier to prevent heat transfer between different building materials, minimizing heat loss or gain.

- Q: What are the different shapes available for steel angles?

- There are several different shapes available for steel angles, each serving a specific purpose in various construction and structural applications. The most common shapes of steel angles include: 1. Equal angles: These angles have equal legs and are formed by bending a single piece of steel. They are commonly used for general structural applications, such as supporting beams and columns. 2. Unequal angles: As the name suggests, these angles have unequal legs and are often used when one leg needs to be longer or shorter than the other. These angles are commonly used in construction, where they provide additional strength and support in various applications. 3. L-shaped angles: These angles have one leg longer than the other, forming an L-shape. They are commonly used for reinforcing corners and edges of structures, providing additional strength and support. 4. T-shaped angles: These angles have a longer leg that extends perpendicular to a shorter leg, forming a T-shape. They are commonly used as lintels or beams to support loads above openings like doors and windows. 5. C-shaped angles: These angles have one side curved inward, forming a C-shape. They are commonly used in applications where the angle needs to fit around a curved or rounded surface, providing structural support and reinforcement. Overall, the availability of different shapes for steel angles allows for a wide range of applications in construction and structural engineering, providing strength, support, and versatility in various projects.

Send your message to us

Angle Steel for Ship, Vessels and Other Steel Structures Building ASTM A276

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords