GB Q235 Steel Angle with High Quality 25*25mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of GB Q235 Steel Angle with High Quality 25*25mm:

1.Standards:GB

2.Length:6m, 12m

3.Material:Q235 or equivalent

4.Size:

Size (mm) | Mass (kg/m) | Size (mm) | Mass (kg/m) |

| 25*25*2.5 | 0.95 | 25*25*3 | 1.124 |

| 25*25*2.7 | 1.02 | 25*25*4 | 1.459 |

Usage & Applications of GB Q235 Steel Angle with High Quality 25*25mm:

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Packaging & Delivery of GB Q235 Steel Angle with High Quality 25*25mm:

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customers' request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customers' request.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 30 to 45 days from the beginning of production.

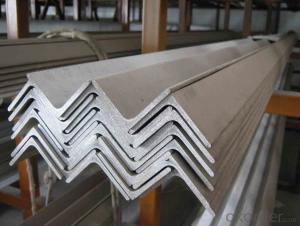

Images of GB Q235 Steel Angle with High Quality 25*25mm:

*If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q: How do you prevent buckling of steel angles under compressive loads?

- To prevent steel angles from buckling under compressive loads, there are several steps that can be taken: 1. Increasing the section modulus: By broadening or thickening the steel angle, its ability to resist bending can be improved, thus enhancing its resistance to compressive loads without buckling. 2. Increasing the moment of inertia: The moment of inertia, which determines a cross-sectional shape's resistance to bending, can be increased by either adding more material or using a different shape with a greater moment of inertia. This makes the steel angle stiffer and less prone to buckling. 3. Providing lateral support: Lateral support can be provided by incorporating bracing or stiffeners into the steel angle. This helps distribute the compressive load and prevents buckling. The bracing or stiffeners should be designed to withstand the applied loads and prevent any local distortions or deformations. 4. Using thicker or higher strength steel: Thicker steel has a higher resistance to bending, while higher strength steel can bear greater stresses before reaching its yield point. By utilizing thicker or higher strength steel, the steel angle can withstand higher compressive loads without buckling. 5. Properly designing and installing connections: The connections between the steel angle and other structural components should be carefully designed and installed. Sufficient connection details should be provided to ensure proper transfer of the compressive load and adequate support for the steel angle. 6. Taking the effective length factor into consideration: The effective length factor is a parameter that considers the buckling behavior of a member. By accurately incorporating the effective length factor into design calculations, the risk of buckling can be minimized. 7. Conducting a comprehensive structural analysis: It is crucial to conduct a structural analysis to determine the expected compressive loads and potential buckling modes. By utilizing appropriate software or calculations, the necessary measures can be implemented to prevent buckling. In conclusion, preventing buckling of steel angles under compressive loads requires a combination of design considerations, material selection, and proper installation techniques. By following these measures, the structural integrity and safety of steel angles can be ensured in various applications.

- Q: How do steel angles differ from steel channels?

- Steel angles and steel channels are both structural steel shapes that are commonly used in construction and engineering applications. However, they differ in terms of their shape and structural properties. Firstly, steel angles have an L-shaped cross-section, with two legs that are perpendicular to each other. The legs can have equal or unequal lengths, depending on the specific application. This L-shaped design provides greater stability and strength, making steel angles ideal for applications that require load-bearing capabilities, such as supporting beams or columns. They are often used in the construction of frames, braces, and for reinforcing structures. On the other hand, steel channels have a U-shaped cross-section, with a flat bottom and two parallel legs that are connected by a vertical web. The legs of steel channels are usually tapered or have rounded edges. The U-shaped design allows steel channels to provide excellent resistance to bending and torsion, making them suitable for applications that require structural support and stability, such as the construction of framing systems, support beams, and building facades. Another key difference between steel angles and steel channels is their weight-bearing capacity. Steel angles, due to their L-shaped design and shorter legs, are generally more efficient in carrying vertical loads. Conversely, steel channels, with their wider and more extensive cross-section, are better suited to bear horizontal loads. In terms of installation, steel angles are typically bolted or welded to other steel members, providing a strong connection. Steel channels, on the other hand, can be connected by welding, bolting, or even by using clips or brackets, depending on the specific application and load requirements. In summary, steel angles and steel channels differ in terms of their cross-sectional shape, load-bearing capacity, and structural properties. Steel angles are L-shaped and are more suited for vertical load-bearing applications, while steel channels are U-shaped and are better suited for horizontal load-bearing applications. Both shapes have their respective advantages and are commonly used in various construction and engineering projects.

- Q: Can steel angles be used for staircases or handrails?

- Yes, steel angles can be used for staircases or handrails. Steel angles provide structural support and can be used to create sturdy and durable staircases and handrails. They are commonly used in construction for their strength and versatility.

- Q: 6# specification for angle iron

- 6# angle steel refers to equal angles, 60 * 60.

- Q: Can steel angles be used in the construction of pipe racks?

- Indeed, the utilization of steel angles is applicable in the construction of pipe racks. Steel angles play a vital role in furnishing the necessary structural support and stability required for pipe racks, thereby rendering them an ideal choice for this particular type of construction. These angles can be employed to fabricate a framework or framework support system for the pipe rack, thereby ensuring its robustness and ability to withstand the weight and pressure exerted by the pipes. Moreover, steel angles possess remarkable durability and resistance to corrosion, which proves crucial in an environment where pipes may be exposed to a variety of elements. In summary, steel angles are an appropriate and commonly utilized material in the construction of pipe racks.

- Q: Can steel angles be used for manufacturing machinery?

- Yes, steel angles can be used for manufacturing machinery. Steel angles are commonly used in the construction industry as structural components due to their strength, durability, and cost-effectiveness. In machinery manufacturing, steel angles can be utilized for various purposes, such as framing, support structures, brackets, and mounting components. They provide stability and rigidity to the machinery, ensuring its structural integrity. Additionally, steel angles can be easily welded, bolted, or riveted, allowing for flexible and efficient fabrication processes. Overall, steel angles are a versatile and reliable choice for manufacturing machinery.

- Q: Do steel angles require any special maintenance?

- No special maintenance is needed for steel angles, but their lifespan can be prolonged with proper care and attention. It is recommended to regularly clean them to remove dirt, debris, and corrosive substances. Additionally, it is important to promptly address any signs of rust, cracks, or damage to prevent further deterioration. To prevent corrosion and extend the life of the steel angles, applying a protective coating or paint is advisable. In general, steel angles require minimal maintenance, but regular inspections and maintenance practices are crucial for optimal performance and longevity.

- Q: How do steel angles perform in terms of electromagnetic shielding?

- Steel angles perform well in terms of electromagnetic shielding due to their high electrical conductivity and magnetic permeability. The angular shape of the steel angles helps to redirect and dissipate electromagnetic waves, effectively reducing the amount of electromagnetic radiation that can pass through. This makes steel angles an excellent choice for applications requiring electromagnetic shielding, such as in electronic enclosures or electromagnetic interference (EMI) shielding.

- Q: How do you determine the required thickness of a steel angle for a specific application?

- In order to calculate the necessary thickness of a steel angle for a particular use, several factors must be taken into account. Firstly, it is crucial to establish the load or weight that will be applied to the steel angle. This includes both the dead load (the weight of the angle itself) and any live loads (external forces or loads placed on the angle). Next, the span or distance between supports needs to be determined. The greater the span, the greater the bending moment and deflection that the steel angle will experience. Once the load and span are known, it becomes necessary to compute the maximum allowable stress or bending moment that the steel angle can endure. This is usually done using engineering formulas or structural analysis software. The maximum allowable stress is determined based on the yield strength of the steel and safety factors. By utilizing the maximum allowable stress and the bending moment, the required section modulus of the steel angle can be calculated. The section modulus measures the angle's resistance to bending and is directly related to its thickness. Lastly, the necessary thickness of the steel angle can be determined by selecting a standard angle size that has a section modulus equal to or greater than the calculated value. It is important to note that other considerations, such as corrosion protection, fire resistance, and aesthetics, may also impact the choice of steel angle thickness. Therefore, it is highly recommended to consult structural engineers or adhere to relevant building codes and standards to ensure the safety and performance of the steel angle in a specific application.

- Q: What are the different types of corrosion that can affect steel angles?

- There are several types of corrosion that can affect steel angles, including: 1. Uniform corrosion: This is the most common type of corrosion and occurs when the entire surface of the steel angle corrodes evenly. It is typically caused by exposure to moisture and oxygen in the environment. 2. Pitting corrosion: Pitting corrosion is characterized by the formation of small pits or holes on the surface of the steel angle. It occurs when localized areas of the metal are exposed to more aggressive corrosive agents, such as chloride ions or acidic substances. 3. Galvanic corrosion: Galvanic corrosion happens when two different metals are in contact with each other in the presence of an electrolyte, such as water or saltwater. The more active metal (the anode) corrodes while the less active metal (the cathode) remains protected. 4. Crevice corrosion: Crevice corrosion occurs in confined spaces or crevices where stagnant water or moisture can accumulate. The lack of oxygen and the concentration of corrosive agents can lead to localized corrosion and degradation of the steel angle. 5. Filiform corrosion: This type of corrosion appears as thread-like filaments that form on the surface of the steel angle. It is typically caused by the presence of moisture and oxygen, as well as the presence of contaminants such as salts or organic compounds. 6. Stress corrosion cracking: Stress corrosion cracking occurs when a combination of tensile stress and a corrosive environment causes cracks to form in the steel angle. It can be particularly dangerous as it can lead to sudden and catastrophic failure of the structure. It is important to note that the severity and likelihood of each type of corrosion can vary depending on factors such as the environment, exposure to corrosive agents, and the quality of the steel angle itself. Regular inspection, maintenance, and appropriate protective coatings can help mitigate the effects of corrosion on steel angles.

Send your message to us

GB Q235 Steel Angle with High Quality 25*25mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords