GB Q235 Steel Angle with High Quality 40*40mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of GB Q235 Steel Angle with High Quality 40*40mm:

1.Standards:GB

2.Length:6m, 12m

3.Material:Q235 or Equivalent

4.Size:

Size (mm) | Mass (kg/m) | Size (mm) | Mass (kg/m) |

| 40*40*3 | 1.852 | 40*40*5 | 2.976 |

| 40*40*4 | 2.422 |

Usage & Applications of GB Q235 Steel Angle with High Quality 40*40mm:

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Packaging & Delivery of GB Q235 Steel Angle with High Quality 40*40mm:

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customers' request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customers' request.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 30 to 45 days from the beginning of production.

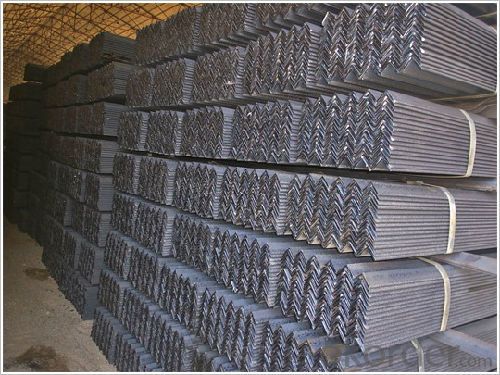

Images of GB Q235 Steel Angle with High Quality 40*40mm:

*If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q: What are the different types of connections used for steel angles in commercial applications?

- In commercial applications, there are several types of connections used for steel angles, depending on the specific requirements and load-bearing capacities of the structure. Some of the common types of connections used for steel angles in commercial applications include: 1. Welded Connections: Welding is a popular method for connecting steel angles in commercial applications. It involves fusing the steel angles together using heat and a filler material. Welded connections provide high strength and rigidity, making them suitable for heavy-duty applications. 2. Bolted Connections: Bolted connections involve using bolts, nuts, and washers to secure the steel angles together. This type of connection offers flexibility and ease of installation. Bolted connections can be easily disassembled and reassembled if needed, making them suitable for structures that may require modification or expansion in the future. 3. Riveted Connections: Riveted connections involve using rivets to join the steel angles. This method is less common in modern commercial applications but was widely used in the past. Riveted connections provide good strength and durability, but they require specialized equipment and skilled labor for installation. 4. Clip Connections: Clip connections are commonly used in light-gauge steel framing systems. They involve using pre-engineered clips that are attached to the steel angles using screws or other fasteners. Clip connections provide a quick and efficient method of assembly, often used in prefabricated structures or systems. 5. Adhesive Connections: Adhesive connections involve using industrial-grade adhesives or epoxy resins to bond the steel angles together. This type of connection offers high strength and can be advantageous in applications where welding or bolting may not be feasible or desirable. It is important to note that the choice of connection method depends on various factors such as the structural requirements, load-bearing capacity, cost, ease of installation, and maintenance considerations. Consulting with a structural engineer or a professional with expertise in steel connections is recommended to ensure the appropriate type of connection is chosen for a specific commercial application.

- Q: How do steel angles perform in high-vibration environments?

- Due to their exceptional structural strength and stability, steel angles are a perfect match for high-vibration environments. Steel's inherent properties, such as its impressive tensile strength and rigidity, enable steel angles to endure dynamic loads and vibrations without compromising their structural integrity. In machinery, construction, and transportation, where vibrations are prevalent, steel angles are widely used. The performance of steel angles in high-vibration environments is also attributed to their L-shaped cross-section design. This configuration provides additional support and resistance against bending and torsional forces, making steel angles more resistant to vibrations compared to other materials. This design feature effectively minimizes the risk of deformation or fatigue that could arise from constant vibrational stress. Furthermore, steel angles can be further reinforced to withstand high-vibration environments through surface treatments and coatings. Techniques such as galvanization or painting can be employed to apply a protective layer that enhances corrosion resistance and prevents the degradation of the steel's mechanical properties. This added protection ensures the long-lasting durability of steel angles in challenging environments. To summarize, steel angles are the perfect choice for high-vibration environments due to their robust nature, L-shaped design, and potential for surface treatments. Their ability to withstand dynamic loads, resist bending and torsional forces, and maintain structural integrity make them dependable and efficient components in various industries where vibration is a concern.

- Q: How do steel angles perform in terms of acoustic insulation?

- Steel angles, being primarily used for structural purposes, do not offer significant acoustic insulation. They are not designed to dampen or block sound transmission. Therefore, if acoustic insulation is a priority, alternative materials or specific soundproofing solutions should be considered.

- Q: Can steel angles be used in outdoor or exposed applications?

- Steel angles can indeed be utilized in outdoor or exposed settings. Typically, they are crafted from galvanized steel, which is covered with a protective zinc layer. This zinc coating aids in averting corrosion and rust, rendering them fitting for outdoor purposes. Moreover, steel angles possess robustness and sturdiness, making them appropriate for a range of applications including construction, infrastructure, and outdoor furnishings. Nonetheless, it is crucial to carry out regular maintenance and inspections to detect any indications of corrosion or harm, taking appropriate measures to forestall possible problems.

- Q: Are steel angles resistant to pests and insects?

- Steel angles are not inherently resistant to pests and insects. While steel itself is not an attractive material for pests and insects, steel angles can still be susceptible to infestation or damage if there are openings or gaps where pests can gain access. Additionally, pests can still cause damage to other materials in the vicinity of the steel angles, which may indirectly affect their overall integrity. Therefore, it is important to ensure that proper pest control measures are in place and that any potential entry points or vulnerabilities are addressed to minimize the risk of pest infestation or damage to steel angles.

- Q: Can steel angles be used in the construction of schools?

- Yes, steel angles can be used in the construction of schools. Steel angles are versatile structural elements that can be used to create strong and durable frameworks for various construction projects, including schools. They are commonly used in the construction industry for their high strength-to-weight ratio, which makes them ideal for supporting heavy loads and providing structural stability. Steel angles can be incorporated into the design of school buildings to reinforce walls, support staircases, create open spaces, or serve as structural components for roofs and ceilings.

- Q: How are steel angles protected against atmospheric corrosion?

- Steel angles are protected against atmospheric corrosion through a variety of methods. One common method is by applying a protective coating, such as paint, to the surface of the steel angles. This coating acts as a barrier between the steel and the surrounding atmosphere, preventing the steel from coming into direct contact with moisture or oxygen, which are the main contributors to corrosion. Another method of protection is through galvanization. Galvanization involves coating the steel angles with a layer of zinc, either through hot-dip galvanization or electroplating. The zinc acts as a sacrificial layer, corroding in place of the steel. This sacrificial corrosion process helps to protect the steel angles from atmospheric corrosion. In addition to coatings, steel angles can also be protected through the use of inhibitors. Inhibitors are substances that are added to the surrounding environment or applied directly to the steel surface to slow down or prevent corrosion. These inhibitors work by either forming a protective film on the steel surface or by altering the chemical environment to make it less corrosive. Regular maintenance and inspection are also essential in protecting steel angles against atmospheric corrosion. This includes cleaning the surface of the steel angles to remove any dirt or debris that may trap moisture and accelerate corrosion. It is also important to promptly repair any damaged or deteriorated coatings to ensure continued protection against corrosion. Overall, a combination of protective coatings, galvanization, inhibitors, and regular maintenance is necessary to effectively protect steel angles against atmospheric corrosion and extend their lifespan.

- Q: What are the advantages of using steel angles?

- There are several advantages of using steel angles. Firstly, steel angles provide excellent structural support due to their high strength and durability. They can withstand heavy loads and extreme weather conditions, making them ideal for construction projects. Additionally, steel angles are versatile and can be easily fabricated, cut, and welded to meet specific design requirements. They are also cost-effective, as they have a long lifespan and require minimal maintenance. Lastly, steel angles offer great aesthetic appeal, making them a popular choice for architectural applications.

- Q: Can galvanized square tubes and angle iron be welded together?

- Yes, if the requirement is not high, it can be welded directly. If the requirement is high, the zinc coating on the galvanized square pipe can be polished off before welding, and then welded. However, two kinds of welding methods, welding well, must be carried out at the weld corrosion. Now there is a special coating for hot-dip galvanizing on the market. It is characterized by high zinc content and 96% zinc content. It can provide similar anticorrosive effect to hot-dip galvanizing for repairing parts.

- Q: What is the maximum temperature that steel angles can withstand?

- The maximum temperature that steel angles can withstand depends on the specific type and grade of steel being used. However, in general, most steel angles can withstand temperatures up to around 1000 to 1200 degrees Celsius (1832 to 2192 degrees Fahrenheit) before they start to lose their structural integrity and strength.

Send your message to us

GB Q235 Steel Angle with High Quality 40*40mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords