angle steel for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

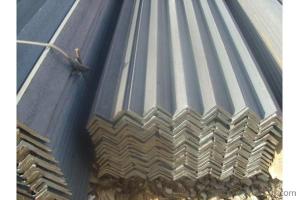

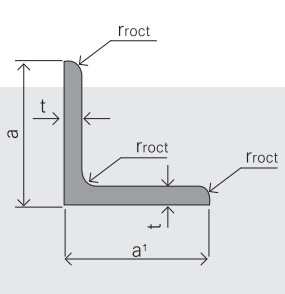

Specifications of Angle Steel

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

4. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

5.Material details:

Usage & Applications of Angle Steel

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Packaging & Delivery of Angle Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

Production flow of Angle Steel

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q: Can steel angles be used for manufacturing playground equipment?

- Indeed, playground equipment can be manufactured using steel angles. Steel angles, renowned for their robustness and endurance, are extensively utilized in construction and manufacturing industries. These angles can be employed to construct the framework and support structures of diverse playground equipment, including slides, climbing frames, and swing sets. The adaptability of steel angles enables the production of secure and steadfast playground equipment capable of enduring rigorous utilization and adverse weather conditions. Furthermore, steel angles can be effortlessly welded, cut, and molded to meet precise design specifications, rendering them an ideal preference for playground equipment manufacturers.

- Q: Can steel angles be used for modular construction?

- Yes, steel angles can be used for modular construction. Steel angles provide structural support and can be easily fabricated and assembled to create modular components in construction projects. They are commonly used for framing, bracing, and connecting modular units, providing strength and stability to the overall structure.

- Q: Are steel angles suitable for seismic design?

- Yes, steel angles are commonly used in seismic design. Steel angles offer several advantages that make them suitable for seismic design. Firstly, steel angles have a high strength-to-weight ratio, which means they can withstand high levels of seismic forces while being relatively lightweight. This is important in seismic design as it allows for the construction of structures that can absorb and dissipate seismic energy efficiently. Secondly, steel angles have excellent ductility, which is the ability to deform without breaking. During an earthquake, structures undergo significant deformations due to ground shaking. Steel angles can absorb these deformations by flexing and bending without compromising their structural integrity. This ductility helps in dissipating the seismic energy and prevents the sudden collapse of the structure. Additionally, steel angles can be easily connected and fabricated, allowing for efficient construction in seismic zones. They can be welded or bolted together to create rigid connections that can resist seismic forces. The versatility of steel angles allows for the design of various structural elements, such as braces, beams, and columns, that can effectively withstand seismic loads. Furthermore, steel angles are highly durable and resistant to corrosion, which is crucial in seismic design. Structures in seismic zones are often exposed to harsh environmental conditions, including moisture and corrosive agents. Steel angles can withstand these conditions and maintain their structural integrity over time. In conclusion, steel angles are suitable for seismic design due to their high strength-to-weight ratio, excellent ductility, ease of fabrication, and resistance to corrosion. These properties make steel angles a reliable choice for constructing structures that can withstand and safely absorb seismic forces.

- Q: How do you protect steel angles from weathering?

- To protect steel angles from weathering, there are several effective methods that can be employed. The most common approach is to apply a protective coating or paint specifically designed for steel surfaces. This coating acts as a barrier, preventing moisture and oxygen from coming into direct contact with the steel and thus reducing the chances of rust formation. It is essential to choose a coating that is weather-resistant and provides long-term durability. Before applying the protective coating, it is crucial to thoroughly clean the steel angles to remove any dirt, grease, or existing rust. This can be done through abrasive cleaning methods such as sandblasting or using a wire brush. After cleaning, the surface should be primed with a corrosion-resistant primer, which enhances the adhesion of the protective coating. Regular maintenance is also essential to ensure the ongoing protection of steel angles from weathering. This includes inspecting the coating periodically for any signs of damage or wear and promptly addressing any issues that arise. Touching up areas where the coating has been compromised is necessary to maintain the integrity of the protective layer. Moreover, proper design and installation techniques can also contribute to protecting steel angles from weathering. Ensuring that the angles are adequately sealed and protected from direct exposure to rain, snow, or other moisture sources is vital. This can be achieved through proper drainage systems, such as gutters or downspouts, to redirect water away from the steel angles. Lastly, considering alternative materials or coatings that are inherently resistant to weathering, such as stainless steel or galvanized steel, can provide an added layer of protection against environmental elements. These materials have a higher resistance to corrosion and are more suitable for outdoor applications where weathering is a concern. By implementing a combination of protective coatings, regular maintenance, proper design, and utilizing weather-resistant materials, steel angles can be effectively protected from weathering and maintain their structural integrity over an extended period.

- Q: How are steel angles different from steel channels?

- Structural steel shapes commonly used in construction and engineering projects include steel angles and steel channels. These shapes differ in both their form and structural characteristics. Steel angles possess an L-shaped cross-section, featuring two legs positioned at right angles to one another. The length of these legs can be equal or unequal, depending on the specific application. Steel angles are frequently employed to provide structural support in various scenarios, such as framing, bracing, and reinforcement. They play a vital role in construction projects, enhancing stability and strength. Conversely, steel channels possess a U-shaped cross-section, with two parallel flanges connected by a web. The flanges are oriented in the same direction, while the web serves as a connecting element. Steel channels are commonly utilized in load-bearing applications, including building frameworks, support beams, and infrastructure projects. These channels are designed to distribute weight evenly and ensure structural stability. Regarding their structural properties, steel angles are renowned for their high strength-to-weight ratio. This characteristic makes them suitable for applications requiring strength and durability. Steel angles can be easily welded, bolted, or riveted, contributing to their versatility and ease of handling. On the other hand, steel channels excel in load-bearing capabilities due to their U-shaped design. The parallel flanges enhance strength and stability, making them ideal for supporting heavy loads and resisting bending or twisting forces. Steel channels are also recognized for their resistance to warping and twisting, ensuring the integrity of the structure. In conclusion, steel angles and steel channels differ in terms of form and structural characteristics. Steel angles possess an L-shaped cross-section and are commonly used in framing and reinforcement, while steel channels possess a U-shaped cross-section and are employed in load-bearing applications. Understanding these disparities is crucial when selecting the appropriate structural steel shape for a construction or engineering project.

- Q: What are the different types of connections for steel angles?

- There are several different types of connections for steel angles, including bolted connections, welded connections, and clip connections. Bolted connections involve using bolts and nuts to secure the angles together, while welded connections are created by melting the edges of the angles together. Clip connections use specially designed clips to hold the angles in place without the need for welding or bolting. Each type of connection has its own advantages and disadvantages, and the choice of connection method depends on factors such as the load-bearing requirements, ease of installation, and cost.

- Q: Can steel angles be used for manufacturing furniture?

- Yes, steel angles can be used for manufacturing furniture. They provide structural support and can be used to create strong and durable furniture pieces. Steel angles are commonly used in industrial and modern furniture designs due to their sleek and minimalist aesthetic.

- Q: What is the typical length of a steel angle?

- The typical length of a steel angle can vary depending on its purpose and application. However, in most cases, the standard length of a steel angle is typically 20 feet or 6 meters. This length allows for easy handling, transportation, and installation in various construction and fabrication projects. However, it's worth noting that steel angles can be cut or customized to shorter lengths to meet specific requirements or fit certain designs.

- Q: What are the common loadings or forces that steel angles are designed to withstand?

- Steel angles are commonly used in various structural applications due to their versatility and strength. These angles are designed to withstand a variety of loadings or forces, depending on the specific application. Some common loadings that steel angles are designed to withstand include: 1. Compression: Steel angles can resist compressive forces, which are forces that tend to squeeze or compress the material. They are often used in columns or supports to bear the weight of a structure or to resist crushing loads. 2. Tension: Steel angles can also withstand tensile forces, which are forces that pull or stretch the material. They are often used in tension members, such as roof trusses or bridge supports, to resist pulling or stretching loads. 3. Bending: Steel angles are designed to resist bending forces, which occur when a material is subjected to a combination of tension and compression. They are commonly used in beams or braces to provide structural stability and prevent excessive deflection or bending. 4. Shear: Steel angles can withstand shear forces, which occur when one section of a material is pushed in one direction and another section is pushed in the opposite direction. They are often used in connections or joints to transfer loads between structural members and resist shearing forces. 5. Lateral loads: Steel angles are also designed to withstand lateral loads, which are forces that act horizontally on a structure. These loads can be caused by wind, earthquakes, or other external factors. Steel angles are often used in bracing systems to provide lateral stability and prevent the structure from overturning or collapsing. It is important to note that the specific loadings and forces that steel angles are designed to withstand may vary depending on the size, shape, and grade of the angle, as well as the specific design requirements of the application. Therefore, it is crucial to consult the appropriate design codes and engineering guidelines to ensure the proper selection and application of steel angles in a given structural design.

- Q: What are the different types of corrosion that can affect steel angles?

- Steel angles can be affected by various types of corrosion, including: 1. Uniform corrosion: This common type of corrosion evenly deteriorates the entire surface of the steel angle. It usually occurs due to exposure to moisture and oxygen in the surrounding environment. 2. Pitting corrosion: Characterized by the formation of small pits or holes on the steel angle's surface, this type of corrosion happens when localized areas of the metal come into contact with more aggressive corrosive agents, such as chloride ions or acidic substances. 3. Galvanic corrosion: When two different metals are exposed to an electrolyte like water or saltwater, galvanic corrosion takes place. In this process, the more active metal (anode) corrodes while the less active metal (cathode) remains protected. 4. Crevice corrosion: Confined spaces or crevices where stagnant water or moisture accumulates can lead to crevice corrosion. The lack of oxygen and the concentration of corrosive agents can cause localized corrosion and degradation of the steel angle. 5. Filiform corrosion: This type of corrosion manifests as thread-like filaments on the steel angle's surface. It is typically triggered by the presence of moisture, oxygen, and contaminants like salts or organic compounds. 6. Stress corrosion cracking: Stress corrosion cracking occurs when a combination of tensile stress and a corrosive environment causes cracks to develop in the steel angle. This type of corrosion is particularly dangerous as it can result in sudden and catastrophic failure of the structure. It is important to acknowledge that the severity and probability of each corrosion type can vary depending on factors such as the environment, exposure to corrosive agents, and the quality of the steel angle. Regular inspections, maintenance, and appropriate protective coatings can help mitigate the impact of corrosion on steel angles.

Send your message to us

angle steel for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords