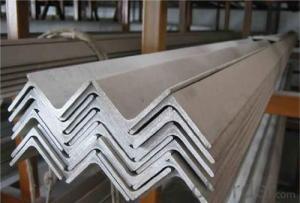

Angel steel for construction high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

General Informaiton of Stainless Steel Angle Bar

1. Grade: SS200, 300,400 series

2. Size: 25×25×3 mm-100×100×10mm

3. Process: HRAP

4. Length: 2-6m

5. Shape: Equal

6. Delivery: within 20 days

7. MOQ: 1 ton

8. Certificate: ISO 9001:2008, SGS

9. Package: Standard Export Packing, or put into wooden boxes according to your requirement

10. Application: Construction, Marine, Industry etc.

Specification of Stainless Steel Angle Bar

Name | Stainless Steel Angles | |||||

Standard | ASTM A554, A312, A249, A269 and A270 | |||||

Material Grade | 304,316,201,202, 316L,430 | |||||

Length | 6m or as customers' request | |||||

Tolerance | a) Thickness: +/-0. 15mm | |||||

b) Length: +/-4. 5mm - 0mm | ||||||

Surface | 180G, 320G, 400G Satin / Hairline(Matt Finish, Brush, Dull Finish) 400G, 500G, 600G or 800G Mirror finish | |||||

Application | Decoration construction, upholstery, industry instruments | |||||

Test | Squash test, Extended test, Water pressure test, Crystal rot test, Heat treatment, NDT | |||||

Chemical Composition of Material | Composition Material | 201 | 202 | 304 | 316 | 430 |

C | ≤0.15 | ≤0.15 | ≤0.08 | ≤0.08 | ≤0.12 | |

Si | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | |

Mn | 5.5-7.5 | 7.5-10 | ≤2.00 | ≤2.00 | ≤1.00 | |

P | ≤0.06 | ≤0.06 | ≤0.045 | ≤0.045 | ≤0.040 | |

S | ≤0.03 | ≤0.03 | ≤0.030 | ≤0.030 | ≤0.030 | |

Cr | 16-18 | 17-19 | 18-20 | 16-18 | 16-18 | |

Ni | 3.5-5.5 | 4-6 | 8-10.5 | 10-14 | ||

Mo | 2.0-3.0 | |||||

Mechanical Property | Material Item | 201 | 202 | 304 | 316 | |

Tensile Strength | ≥535 | ≥520 | ≥520 | ≥520 | ||

Yield Strength | ≥245 | ≥205 | ≥205 | ≥205 | ||

Extension | ≥30% | ≥30% | ≥35% | ≥35% | ||

Hardness (HV) | <253 | <253 | <200 | <200 | ||

- Q: What is the maximum allowable torsional buckling stress for a steel angle?

- The torsional buckling stress limit for a steel angle is determined by multiple factors, including the steel's material properties, the angle's geometry, and the applied load conditions. Torsional buckling occurs when a member twists due to torque, leading to instability and potential failure. To prevent this, design codes and standards offer guidelines and formulas for determining the maximum allowable stress. One example is the American Institute of Steel Construction (AISC), which provides a formula in their Steel Construction Manual for calculating torsional buckling stress. This formula considers the angle's section properties, such as the moment of inertia and radius of gyration, as well as the member's slenderness ratio and effective length. It's important to note that the maximum allowable torsional buckling stress varies based on specific design requirements and safety factors applied during the design process. Therefore, consulting relevant design codes and a structural engineer is crucial to determine the specific maximum allowable torsional buckling stress for a given steel angle in a particular design scenario.

- Q: Can steel angles be used in outdoor applications?

- Yes, steel angles can be used in outdoor applications. Steel angles are commonly used in construction projects, including outdoor structures such as fences, gates, and outdoor staircases. They are also widely used in outdoor equipment and machinery, such as support brackets for solar panels or frames for outdoor signage. Steel angles are highly durable and resistant to corrosion, making them suitable for withstanding outdoor elements such as rain, wind, and sunlight. Additionally, steel angles can be galvanized or coated with protective finishes to further enhance their resistance to rust and other forms of corrosion. Overall, steel angles are a versatile and reliable choice for outdoor applications due to their strength, durability, and weather resistance.

- Q: What are the different surface treatments available for steel angles?

- Steel angles can be treated with different surface treatments, each with its own advantages and uses. Some common surface treatments for steel angles are galvanization, painting, powder coating, and hot-dip coating. Galvanization involves applying a layer of zinc to the steel angles. This treatment offers excellent protection against corrosion, making it suitable for outdoor and marine applications. The zinc layer acts as a sacrificial barrier, safeguarding the steel from rust and other forms of corrosion. Another popular surface treatment for steel angles is painting. This involves adding a coat of paint to the angles, providing both aesthetic appeal and protection. The paint can be customized to match specific color requirements and offers additional resistance against environmental factors like moisture and UV radiation. Powder coating is a technique that involves applying a dry powder to the angles and then heating it to create a durable and attractive coating. This treatment offers exceptional resistance to scratches, chemicals, and fading, making it a preferred choice for industrial and architectural applications. Powder coating also provides a wide range of color options and a smooth, even finish. Hot-dip coating is a process where the angles are immersed in molten zinc. This creates a thick, bonded coating that offers exceptional corrosion resistance. Hot-dip coating is commonly used in industries like construction, infrastructure, and automotive, where the angles will be exposed to harsh environments. To summarize, there are various surface treatments available for steel angles, including galvanization, painting, powder coating, and hot-dip coating. Each treatment offers unique benefits and protection, making steel angles suitable for different industries and applications.

- Q: What are the different types of steel angles used in material handling equipment?

- There are several types of steel angles commonly used in material handling equipment, including equal angles, unequal angles, and L-shaped angles.

- Q: Are there any specific design considerations when using steel angles?

- Yes, there are several specific design considerations when using steel angles. These include determining the appropriate size and thickness of the angle to ensure structural stability and load-bearing capacity, considering the angle's orientation and connection details for proper installation, and accounting for any potential deflection or buckling issues that may arise due to the long and slender nature of angles. Additionally, it is important to consider the corrosion resistance of steel angles in certain environments and to select the appropriate coatings or treatments to mitigate this potential issue.

- Q: What are the different types of steel angles used in agricultural applications?

- There are several different types of steel angles commonly used in agricultural applications. 1. Equal Angle: This type of steel angle has equal sides and is often used for structural support in agricultural buildings, such as barns and sheds. It provides stability and strength, making it suitable for load-bearing applications. 2. Unequal Angle: As the name suggests, this steel angle has unequal sides, with one side longer than the other. It is commonly used in agricultural machinery, such as tractor attachments and implements. The unequal sides allow for better positioning and attachment of various components. 3. Lipped Angle: Lipped angles are similar to equal angles but have an additional lip or flange on one side. This lip provides added support and rigidity, making it ideal for agricultural applications that require extra strength, such as fencing and gate posts. 4. Slotted Angle: Slotted angles are versatile and can be adjusted to different angles as needed. They are commonly used in agricultural shelving systems, allowing farmers to create custom storage solutions for tools, equipment, and supplies. The slots in the angles provide flexibility for adjusting shelf heights. 5. Rolled Steel Angle: Rolled steel angles are produced by rolling steel into angle-shaped sections. They are commonly used in agricultural construction for bracing, supporting beams, and framing. Rolled steel angles offer high strength and durability, making them suitable for demanding agricultural environments. Each type of steel angle has its unique characteristics and advantages, and the choice depends on the specific agricultural application and the level of strength and support required. It is important to consider factors such as load-bearing capacity, durability, and resistance to corrosion when selecting the appropriate steel angle for agricultural use.

- Q: Which is cheaper, angle iron or steel pipe?

- Steel tube (Steel pipe) production technology development began in the bicycle manufacturing industry, the rise of the early nineteenth Century during the oil development, the two world war ships, boilers, aircraft manufacturing, manufacturing of power boiler after the Second World War, the development of chemical industry of petroleum and natural gas drilling and transportation, will effectively promote the the yield and quality of varieties, the development of steel tube industry.

- Q: What are the common defects or issues found in steel angles?

- Some common defects or issues found in steel angles include surface imperfections such as cracks, scratches, or dents, dimensional variations such as uneven or inconsistent lengths, widths, or thicknesses, and improper alignment or straightness. Other issues can include corrosion, rusting, or lack of proper coating, as well as inadequate welding or joining, leading to weak or compromised structural integrity.

- Q: Can steel angles be used in telecommunications tower constructions?

- Yes, steel angles can be used in telecommunications tower constructions. Steel angles are commonly used in the construction of telecommunications towers due to their strength, durability, and ability to provide structural support. They can be utilized for various purposes such as bracing, cross arms, or mounting equipment, making them an essential component in telecommunications tower construction.

- Q: Can steel angles be used for temporary or removable structures?

- Yes, steel angles can be used for temporary or removable structures. Steel angles provide structural support and stability, making them suitable for various applications such as scaffolding, temporary frames, or modular structures that can be easily assembled and disassembled.

Send your message to us

Angel steel for construction high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches