Aluminum Extrusion Profiles from Japan for Honda Spareparts

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Extrusion For Honda Spareparts Description:

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of the Aluminium Extrusion For Honda Spareparts:

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

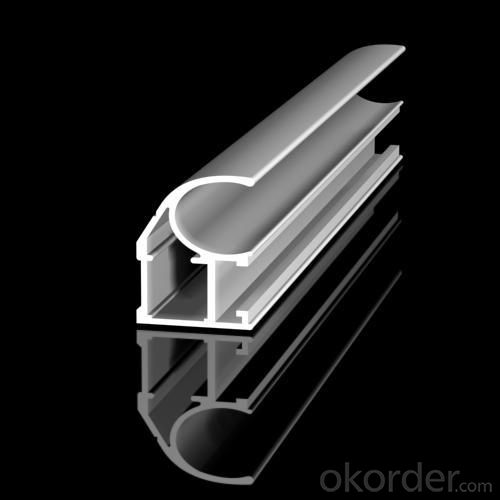

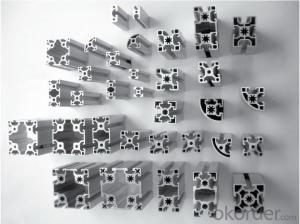

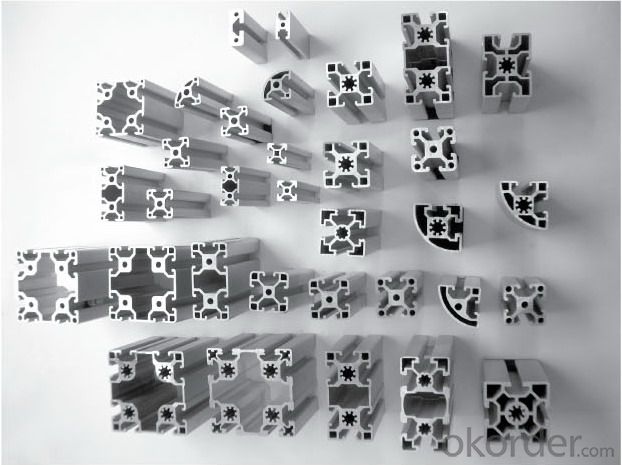

Images of the Aluminium Extrusion For Honda Spareparts:

Aluminium Coins for Deep Drawing to Tube Comestic Specification:

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q: Can aluminum profiles be used for modular storage systems?

- Yes, aluminum profiles can be used for modular storage systems. Aluminum is a lightweight and durable material that is commonly used in various industries, including storage and shelving systems. Its versatility allows for easy customization and the ability to create modular units that can be easily assembled, disassembled, and reconfigured as needed. Additionally, aluminum profiles provide a sleek and modern aesthetic to storage systems.

- Q: Can aluminum profiles be cut to size?

- Indeed, it is possible to cut aluminum profiles to fit specific dimensions. Typically, manufacturers produce aluminum profiles in standardized lengths, which can then be readily adjusted to the desired length or size through diverse cutting techniques such as sawing, shearing, or CNC machining. As a result, aluminum profiles offer personalized options and adaptability for a variety of applications.

- Q: Are there any limitations on the length of aluminum profiles?

- Yes, there are limitations on the length of aluminum profiles. The length of aluminum profiles is typically limited by factors such as the manufacturing process, transportation constraints, and practicality. In terms of manufacturing, aluminum profiles are usually extruded or rolled, and the length is limited by the equipment and capabilities of the manufacturer. Extrusion presses and rolling mills have certain size limitations, which determine the maximum length of aluminum profiles that can be produced. Transportation constraints also play a role in limiting the length of aluminum profiles. Longer profiles may be difficult to transport due to logistical challenges, such as the size of trucks or shipping containers. Moreover, the risk of damage or deformation during transportation increases with longer profiles. Practicality is another factor that imposes limitations on the length of aluminum profiles. Longer profiles may become less rigid and more prone to sagging or bending under their own weight, making them less suitable for certain applications. Additionally, longer profiles may be more difficult to handle and install, requiring specialized equipment and techniques. While there are limitations on the length of aluminum profiles, manufacturers can often produce profiles in various lengths to meet specific project requirements. However, it is important to consider these limitations and consult with the manufacturer to determine the feasibility of producing longer profiles if needed.

- Q: How much is the aluminium frame Aonaike surface over three thickness? And three prism specifications?

- The thickness of the aluminum profile is 1.8mm, and the size of the three prism is 136126100,80.

- Q: This question asks for a comparison of aluminum profiles with other materials regarding their weight and strength characteristics.

- <p>Aluminum profiles are known for their high strength-to-weight ratio, making them lighter than many other materials while maintaining significant strength. Compared to steel, aluminum is approximately one-third the weight but offers comparable strength, especially in alloy forms. When compared to plastics, aluminum profiles have greater rigidity and durability. They also resist corrosion and are more heat resistant than many plastics. However, aluminum profiles are generally more expensive than plastics and some steels. In summary, aluminum profiles offer a balance of low weight and high strength, making them suitable for applications where weight savings and structural integrity are crucial.</p>

- Q: What screws do you use for aluminum alloy profiles?

- This depends on what position is used, I do window and curtain wall, the use of nails, including machine silk, self tapping nails, self drilling, drilling nails and so on. Stainless steel, galvanized, also useful.

- Q: Explain the advantages of utilizing aluminum profiles in the construction industry.

- <p>Aluminum profiles offer several benefits in construction, including high strength-to-weight ratio, which means they are strong yet lightweight. This reduces the load on structures and facilitates easier handling and installation. They are also corrosion-resistant, ensuring longevity and low maintenance costs. Aluminum profiles are recyclable and environmentally friendly, contributing to sustainable construction practices. Their malleability allows for versatile design and customization, accommodating various architectural needs. Additionally, they have excellent thermal conductivity, which can be beneficial for heat management in buildings. Lastly, their aesthetic appeal and modern look enhance the visual appeal of construction projects.</p>

- Q: What are the different extrusion methods used for aluminum profiles?

- There are several different extrusion methods used for aluminum profiles, including direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. Each method has its own advantages and is suited for specific applications. Direct extrusion involves pushing the aluminum billet through a die to create the desired shape, while indirect extrusion involves the billet being held stationary and the die moving towards it. Impact extrusion involves forcing the aluminum into a die cavity using a high-velocity impact, and hydrostatic extrusion uses high-pressure fluid to push the aluminum through the die.

- Q: This question asks about the various finishing options that can be applied to aluminum profiles.

- <p>Aluminum profiles can be finished in several ways to enhance their appearance and durability. Common types of finishes include: 1. Anodizing, which provides a protective oxide layer and can be colored. 2. Powder coating, a durable and customizable finish that offers a wide range of colors and textures. 3. Electrophoretic coating, which results in a smooth, even finish and is often used for automotive parts. 4. Polishing, which can produce a mirror-like finish. 5. Brushing, which creates a鍝戝厜 texture with a satin-like appearance. 6. Painting, which can be done with solvent-based or water-based paints for a variety of color options. 7. Wood grain transfer, which gives aluminum profiles the appearance of wood. Each finish has its own advantages and is chosen based on the specific application and aesthetic requirements.</p>

- Q: Is it possible to incorporate recycled aluminum extrusions into a construction project?

- <p>Yes, you can use recycled aluminum extrusions in your building project. Recycled aluminum is not only environmentally friendly but also offers the same strength and durability as new aluminum. It is commonly used in construction for framing, window and door profiles, and structural components. Ensure that the recycled aluminum meets the required industry standards for your project to guarantee quality and performance.</p>

Send your message to us

Aluminum Extrusion Profiles from Japan for Honda Spareparts

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords