Aluminum Profiles for Exhibition Stands:Custom Length LED Strip Light Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Profile For Led Strip Light And Length Customed Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminum Profile For Led Strip Light And Length Customed:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

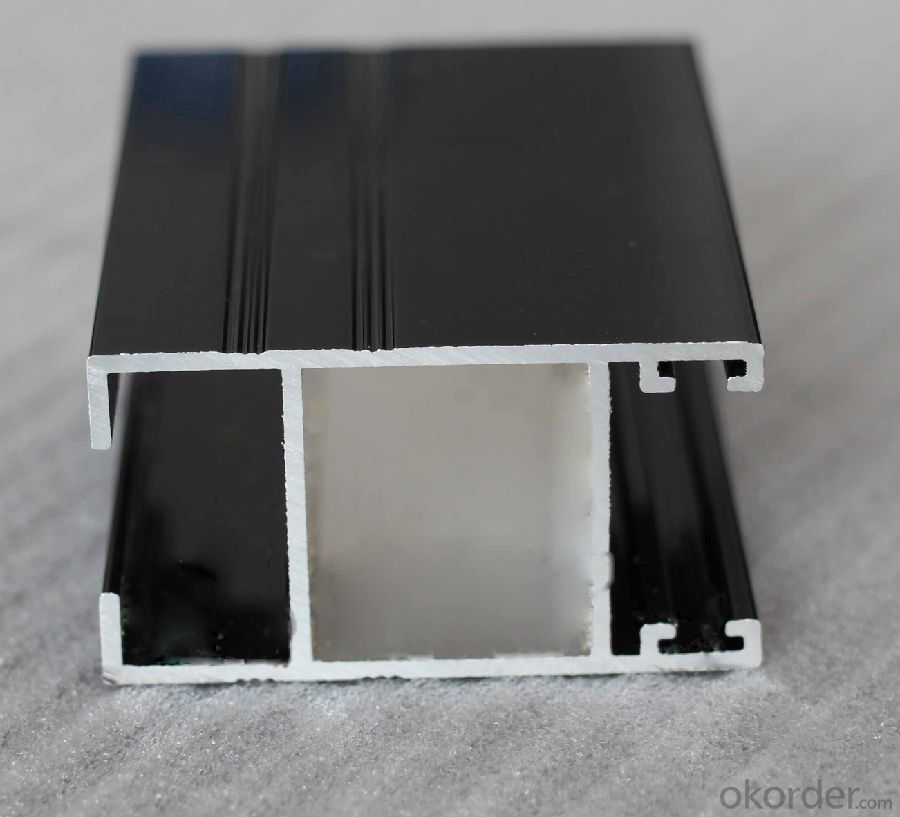

3.Aluminum Profile For Led Strip Light And Length Customed Images:

4.Aluminum Profile For Led Strip Light And Length Customed Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Can aluminum profiles cross Luo? Why is the appearance of an aluminum profile component of a Japanese original machine extremely close to that of Luo Luo? Why? Why?

- Companies adhere to the "quality first, reputation first, service first" purpose, the spirit of innovation and sincere and trustworthy manner, first-class products, first-class brand, first-class performance is our consistent pursuit, we sincerely welcome domestic and foreign merchants to visit the company and guide.

- Q: What are the regular colors of aluminum profiles?

- The regular colors of aluminum profiles of different treatment processes are as follows:Electrophoresis: Champagne, silver, bronze, stainless steel color, golden yellow, blackOxidation: Champagne, silver, bronze, stainless steel color, golden yellow, blackSpraying: any colorAluminum in the paint before the first oxidation of aluminum extrusion profiles, Aluminum Alloy good corrosion resistance, the surface is not strong, should be to increase the aluminum corrosion resistance, wear resistance and surface by anodic oxidation surface treatment of the appearance of the.

- Q: Can aluminum profiles be used in the production of signage?

- Yes, aluminum profiles can be used in the production of signage. Aluminum profiles are popular in the signage industry due to their durability, versatility, and aesthetic appeal. They can be easily shaped and cut into various sizes and designs, making them suitable for different types of signage such as indoor and outdoor signs, lightboxes, channel letters, and more. Aluminum profiles are also lightweight, corrosion-resistant, and weatherproof, allowing them to withstand harsh environmental conditions and ensure long-lasting signage. Additionally, aluminum profiles can be easily painted, powder-coated, or anodized in different colors, providing endless design possibilities for signage projects. Overall, using aluminum profiles in signage production offers numerous advantages in terms of durability, customization, and visual appeal.

- Q: Can aluminum profiles be used in marine vessel manufacturing?

- Marine vessel manufacturing can indeed utilize aluminum profiles. Boats and other marine vessels are commonly constructed using aluminum due to its exceptional characteristics. Lightweight, durable, and resistant to corrosion, aluminum proves to be an ideal material for marine environments. It can endure the effects of saltwater exposure, a prevalent concern in marine applications. Moreover, aluminum profiles can be effortlessly shaped, welded, and interconnected, facilitating efficient and customizable vessel designs. This adaptability renders aluminum highly appealing to boat builders and manufacturers.

- Q: Hangzhou aluminum how much money one meter, where can wholesale?

- Decoration materials market, your question is too general profile a variety of non-standard standard and non-standard decoration for many non-standard to open mold and MOQ is non-standard aluminum ingot processing fee plus 5000 yuan I hope to help you. Thank you!

- Q: What are the advantages of using aluminum profiles in window and door frames?

- Using aluminum profiles in window and door frames comes with several benefits. To begin with, aluminum is a lightweight material, making it easier to handle during installation and maintenance. This simplifies the overall construction process and reduces costs. In addition, aluminum is highly durable and resistant to corrosion, ensuring that window and door frames have a longer lifespan. Unlike materials like wood or steel, aluminum does not rot, warp, or rust when exposed to moisture or extreme weather conditions. This durability leads to lower maintenance and replacement expenses over time. Moreover, aluminum profiles provide excellent thermal insulation properties. They can be designed with thermal breaks or insulating materials, effectively preventing heat or cold transfer between the interior and exterior of a building. As a result, energy efficiency is improved and heating and cooling costs are reduced. Furthermore, aluminum profiles can be easily customized to meet various design requirements. They are available in a wide range of shapes, sizes, and finishes, offering flexibility in architectural designs. Whether it's a modern or traditional style, aluminum profiles can be tailored to meet specific aesthetic preferences. Additionally, aluminum is a sustainable and environmentally friendly material. It is 100% recyclable without losing its properties, making it an ideal choice for those concerned about reducing their carbon footprint. Lastly, aluminum profiles offer enhanced security features. They can be reinforced with additional locking mechanisms and impact-resistant glass, providing better protection against break-ins and ensuring the safety of occupants. In conclusion, the advantages of using aluminum profiles in window and door frames include their lightweight nature, durability, thermal insulation properties, customization options, sustainability, and enhanced security features. Opting for aluminum profiles can result in long-term cost savings, energy efficiency, and aesthetic appeal for any building project.

- Q: Is it possible to use aluminum profiles as materials for flooring?

- <p>Aluminum profiles can indeed be used for flooring materials, particularly in industrial or commercial settings. They are valued for their strength, durability, and resistance to corrosion. Aluminum profiles are often used in modular flooring systems, providing a stable and customizable base that can be easily adjusted or reconfigured. They are also appreciated for their lightweight nature, which can reduce the load on structures and facilitate installation. However, for residential applications, traditional flooring materials like wood, tile, or carpet are more common due to aesthetic and comfort considerations.</p>

- Q: What are the reasons for the large number of products in the aluminum profile cutting machine after opening?

- Possible saw blades, what kind of saw blades do you use, and aluminum profiles?

- Q: This question asks for a comparison between aluminum profiles and other materials used in constructing frames, focusing on their characteristics and performance.

- <p>Aluminum profiles are favored for building frames due to their high strength-to-weight ratio, making them lightweight yet durable. They offer excellent corrosion resistance, which is superior to materials like steel, which can rust. Aluminum profiles are also easy to machine and form, allowing for complex designs. Compared to wood, they are more resistant to weathering and pests. However, they may not have the same aesthetic appeal as wood or the thermal insulation properties of some plastics. Overall, aluminum profiles are a strong choice for structural integrity and longevity in frame construction.</p>

- Q: How do aluminum profiles compare to other types of materials?

- Aluminum profiles have several advantages over other types of materials. Firstly, aluminum is lightweight, making it easier to handle and transport. It is also highly resistant to corrosion, making it ideal for outdoor or high-moisture environments. Additionally, aluminum profiles offer excellent strength-to-weight ratio, providing structural stability without unnecessary weight. Moreover, aluminum is a highly versatile material that can be easily shaped and customized to meet specific design requirements. Lastly, aluminum is sustainable and recyclable, making it an environmentally friendly choice. Overall, aluminum profiles offer numerous benefits in terms of durability, versatility, and sustainability compared to other materials.

Send your message to us

Aluminum Profiles for Exhibition Stands:Custom Length LED Strip Light Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords