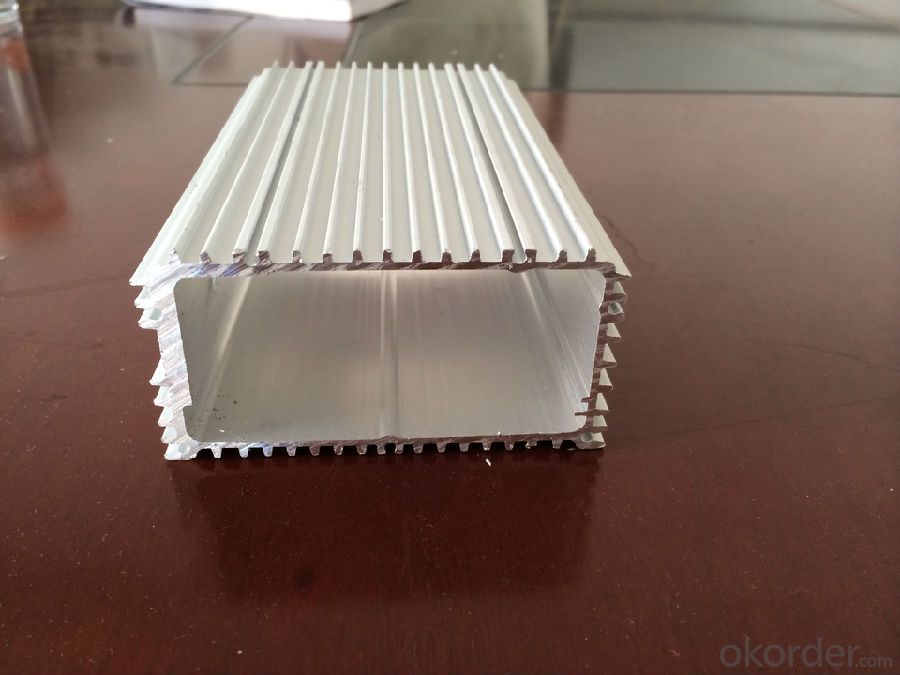

Solidworks Aluminum Weldment Profiles:Sunflowers for Heat Sink Aluminum Profile

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

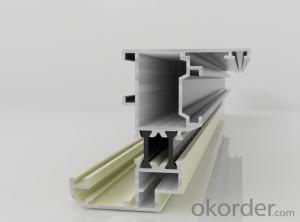

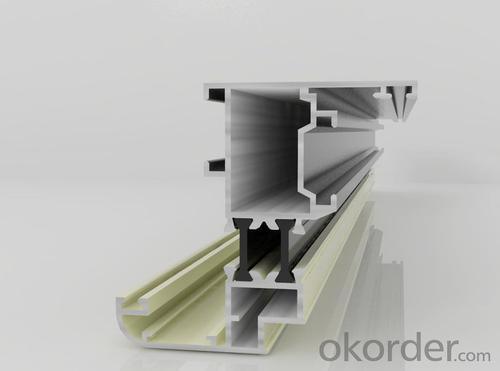

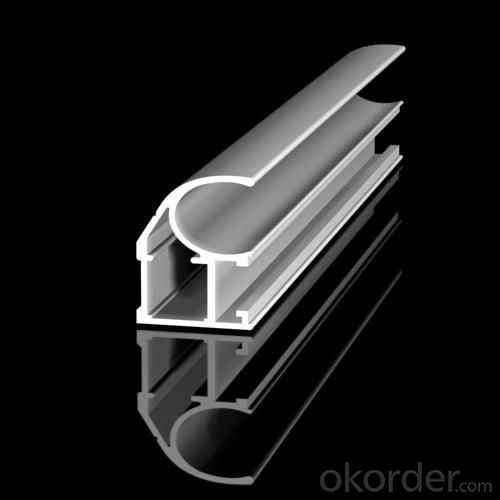

Structure of Aluminum Profile Sunflowers For Heat Sink Description:

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of the Aluminum Profile Sunflowers For Heat Sink:

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

Images of the Aluminum Profile Sunflowers For Heat Sink:

Aluminum Profile Sunflowers For Heat Sink Specification:

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q: What are the different surface treatments for aluminum profiles?

- Some of the different surface treatments for aluminum profiles include anodizing, powder coating, painting, and polishing.

- Q: This question asks for methods to reduce waste associated with the production and utilization of aluminum profiles in the construction industry.

- <p>To minimize waste during the production and use of aluminum profiles in construction, one can adopt several strategies: 1. Optimize production processes to reduce material waste by using precision cutting and advanced manufacturing techniques. 2. Implement recycling programs to repurpose scrap aluminum, reducing the need for raw material extraction. 3. Design buildings with modular aluminum components that can be easily disassembled and reused in future projects. 4. Educate construction workers on proper handling and storage to prevent damage and waste. 5. Use computer-aided design (CAD) to accurately plan material requirements, minimizing offcuts. 6. Choose sustainable aluminum sources and suppliers that prioritize waste reduction. 7. Regularly audit and update production methods to incorporate new waste reduction technologies and practices.</p>

- Q: What are the necessary upkeep and care procedures for aluminum profiles post-installation?

- <p>After installation, aluminum profiles generally require minimal maintenance due to their corrosion resistance and durability. However, regular cleaning to remove dust and dirt is recommended to maintain their aesthetic appeal and performance. This can be done using mild detergents and water. Periodic inspection for any signs of damage or wear is also important to ensure the structural integrity of the profiles. In case of any damage, it should be promptly attended to to prevent further deterioration. Despite their low maintenance nature, it's crucial to follow the manufacturer's guidelines for care and upkeep to prolong the life of the aluminum profiles.</p>

- Q: This question asks about the variety of colors offered for aluminum profiles used in exterior siding and trim applications.

- <p>Aluminum profiles for siding and trimming are available in a wide range of colors to suit various architectural styles and design preferences. Common colors include white, black, brown, beige, and gray, which are popular for their neutrality and versatility. Additionally, there are bolder options such as red, blue, green, and yellow for more distinctive looks. Some manufacturers also offer custom color matching services for specific projects. The finishes can be powder-coated or anodized, providing durability and resistance to weathering. It's always best to check with specific manufacturers for the most up-to-date color offerings as they may introduce new colors or discontinue others based on market trends.</p>

- Q: How do aluminum profiles perform in load-bearing structures?

- Aluminum profiles are known for their excellent performance in load-bearing structures. Due to their high strength-to-weight ratio, aluminum profiles offer significant advantages over other materials in terms of structural integrity and overall weight reduction. The inherent strength of aluminum profiles enables them to support heavy loads, making them suitable for various load-bearing applications. Whether it is in buildings, bridges, or industrial structures, aluminum profiles can effectively withstand and distribute heavy loads, ensuring reliable and safe performance. Additionally, aluminum profiles have exceptional corrosion resistance, which is crucial for load-bearing structures exposed to harsh environments or outdoor conditions. This corrosion resistance ensures the longevity and durability of the structure, reducing maintenance and replacement costs in the long run. Furthermore, aluminum profiles are highly versatile and can be easily customized to meet specific design requirements. They can be extruded into various shapes and sizes, allowing for efficient integration into complex load-bearing structures. This versatility also enables the use of aluminum profiles in unique architectural designs, enhancing the aesthetics of the structure. Another advantage of aluminum profiles in load-bearing structures is their lightweight nature. Compared to traditional materials like steel, aluminum profiles are significantly lighter, resulting in easier and more cost-effective transportation, installation, and overall construction process. This makes aluminum profiles an ideal choice for projects where weight reduction is a priority. In conclusion, aluminum profiles excel in load-bearing structures due to their high strength-to-weight ratio, corrosion resistance, versatility, and lightweight properties. These characteristics make aluminum profiles a reliable and efficient choice for various load-bearing applications, providing durability, longevity, and cost-effectiveness to the overall structure.

- Q: What's the price of aluminum alloy die castings and aluminum profiles?

- In fact, the price is different, mainly depends on quality

- Q: Can aluminum profiles be used in signage or display applications?

- Signage or display applications can utilize aluminum profiles effectively. These profiles possess versatility and lightness, making them perfect for producing durable and visually pleasing signs and displays. They can be easily cut, shaped, and connected together to form personalized frames, panels, and structures for various signage and display purposes. Moreover, aluminum profiles possess exceptional resistance to corrosion, ensuring that the signs or displays remain intact and attractive even in outdoor or high-moisture environments. Additionally, the option to powder coat or anodize aluminum profiles offers a wide array of color choices, enabling branding or customization. In summary, aluminum profiles offer a dependable and cost-effective solution for signage or display applications, providing both practicality and aesthetics.

- Q: What are the different surface brushing options for aluminum profiles?

- Aluminum profiles offer a range of surface brushing options, each with its own distinctive appearance and practical features. 1. Mechanical Brushing: By utilizing abrasive brushes or pads, a consistent brushed pattern is created on the surface of the aluminum profile. This linear finish enhances the material's visual appeal and effectively conceals minor imperfections and scratches, making it a favored option for decorative purposes. 2. Chemical Brushing: Also referred to as chemical etching, this technique involves the application of a chemical solution to the aluminum profile's surface. The solution selectively removes a thin layer of metal, resulting in a brushed effect. Manufacturers can control the intensity of brushing to achieve different levels, enabling them to create matte or satin finishes. 3. Sandblasting: This surface treatment method entails propelling fine particles onto the aluminum profile's surface at high speeds. The abrasive particles remove the outer layer of metal, producing a textured brushed finish. Sandblasting can be adjusted to achieve varying degrees of roughness and depth, making it suitable for diverse applications. 4. Wire Brushing: Wire brushing is a manual technique that employs a wire brush to create a brushed pattern on the aluminum profile's surface. It allows for precise control over the direction and intensity of brushing, making it a suitable choice for customized designs. Depending on the pressure applied and the type of brush used, wire brushing can achieve both light and heavy brushed finishes. 5. Anodizing: Anodizing is an electrochemical process that involves forming an oxide layer on the surface of the aluminum profile. This process not only enhances the material's corrosion resistance but also allows for the application of various decorative finishes, including brushed patterns. Prior to anodizing, aluminum profiles can undergo mechanical brushing or chemical etching to achieve the desired brushed effect. In conclusion, the selection of a surface brushing option for aluminum profiles depends on the desired finish, functionality, and specific application requirements. Manufacturers consider factors such as aesthetic appeal, durability, corrosion resistance, and ease of maintenance when choosing the appropriate technique.

- Q: Are aluminum profiles suitable for use in the renewable energy industry?

- Aluminum profiles are well-suited for the renewable energy sector, offering numerous benefits. To begin with, aluminum is a versatile and lightweight material, making it ideal for renewable energy applications. The corrosion resistance of aluminum profiles is exceptional, allowing them to withstand outdoor conditions and moisture exposure. This durability ensures the longevity and structural integrity of the profiles. Moreover, the recyclability of aluminum profiles makes them an environmentally friendly choice for the renewable energy industry. With the industry's focus on reducing carbon footprint and promoting sustainability, aluminum's recyclability plays a crucial role in achieving these objectives. Aluminum can be recycled repeatedly without losing its essential properties, reducing the necessity for extracting and processing new raw materials. Another advantage of aluminum profiles is their design flexibility, enabling the creation of intricate shapes and structures tailored to specific requirements. This versatility makes them suitable for various renewable energy applications, including solar panel frames, wind turbine components, and mounting systems. Additionally, the lightweight nature of aluminum profiles simplifies transportation and installation processes, resulting in cost and energy savings. In conclusion, the corrosion resistance, recyclability, design flexibility, and lightweight properties make aluminum profiles an excellent choice for the renewable energy industry. These characteristics contribute to the efficiency, durability, and sustainability of renewable energy systems, establishing aluminum profiles as a fitting material for this sector.

- Q: Can aluminum profiles be used in the construction of modular office spaces?

- Yes, aluminum profiles can definitely be used in the construction of modular office spaces. Aluminum profiles are lightweight, durable, and have excellent structural integrity, making them an ideal choice for modular construction projects. They can be easily fabricated and assembled to create various components such as walls, partitions, doors, windows, and framing systems for modular office spaces. Additionally, aluminum profiles offer great design flexibility, allowing for customization and adaptation to different office layouts and requirements. They are also highly resistant to corrosion, which is particularly beneficial in office environments where moisture and humidity can be present. Overall, aluminum profiles provide numerous advantages in terms of strength, versatility, and aesthetics, making them a popular choice for construction in modular office spaces.

Send your message to us

Solidworks Aluminum Weldment Profiles:Sunflowers for Heat Sink Aluminum Profile

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords