Solidworks Aluminum Weldment Profiles for Aluminum Window and Door Frame CNBM Hot Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.2

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Profile

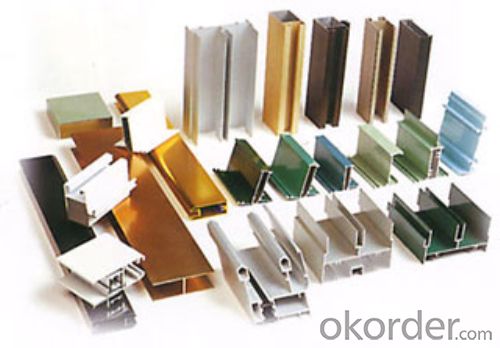

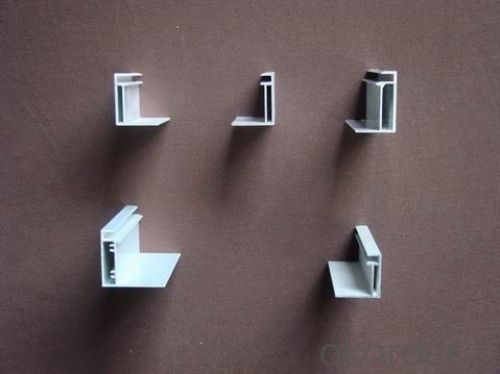

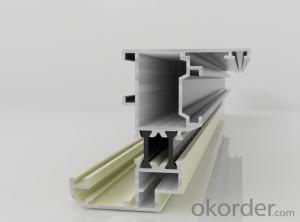

Products Introduction of Aluminum Profile

Aluminum ProfileAluminum frame is made from aluminum and minerals. It's raw matrial for window frame, window frame, and other equipment frame. It's easy for construction, cost less, service longer than other materails. The size and design can be customerized.

Advantage of Aluminum Frame

-Build FLEXIBLE equipment, window, door.

-Bolt your structure together

-Build with Aluminum MORE EASILY

-Aluminum costs LESS

-Service life is more than 10 years

-Can be customerized

Specifications

(1) Product: Aluminium Frame;

(2) Material: Alloy 6063/6061/6005/6060, T5/T6;

(3) Finish: anodizing, powder coating, wooden, electrophoresis or any color;

(4) Size: customized, same as drawings or samples;

(5) Standard: High-quality;

(6) Characteristics: strong, stylish, durable, corrosion-resistant.

Aluminium Alloy: 6063, 6061, 6005, 6060 Thermal Treatment: T5, T6

Section Shapes

I, U, T, C, Z, L, H, square, round, flat, hollow, t-slot, and other complicated shapes by custom design.

Surface treating

Mill / Anodizing (oxidation) / Sand blasting / Powder Coating / Electrophoresis / PVDFCoating / Wood effect.

Application

1) - for Window and door frames, for Wardrobe cabinet sliding doors, kitchen, for Building curtain glass walls

2) -for Fencing, Rail, Deck and Frame.

3) - for Solar panel frames, solar mounting / roofing brackets

4) - for Industry assembly lines equipment.

5) - for Heatsinks, for LED lighting.

7) - other by custom design size and dimension

FAQ

-What's your company profile?

We CNBM is the largest building material supplier of China. We are Chinese government owned corporation, which takes the 267th place in WOLD FORTUNE 500 CORPORATION. We own the largest prodcution base in North and South of China. With more than 15 warehouses and offices in different countries, our products sell very well all over the world. We have whole quality control system. We'll be your reliable partner.

-Which kind of payment do you usually support?

TT, LC at sight.

-Can you provide samples?

Yes, we provide free of charge samples, you just need to pay for the delivery.

Photos:

- Q: This question asks for a description of the various forms and dimensions of aluminum profiles that are typically utilized in the construction industry.

- <p>Aluminum profiles used in construction come in various shapes and sizes to cater to different structural needs. Common shapes include angles, channels, I-beams, H-beams, T-profiles, and rectangular or square tubes. Sizes vary based on the thickness of the aluminum and the dimensions of the profile, such as width, height, and length. For instance, an H-beam might have a depth ranging from 100mm to 900mm and a width from 50mm to 300mm. The selection of the right profile depends on the specific requirements of the construction project, such as load-bearing capacity, aesthetic considerations, and cost efficiency.</p>

- Q: This question asks for the various types of aluminum profiles that are utilized in roofing systems.

- <p>Aluminum profiles for roofing systems come in various types, each serving specific purposes. Common types include: 1. <strong>Gutter Profiles</strong>: Used for collecting and directing rainwater from the roof. 2. <strong>Fascia Profiles</strong>: Cover the ends of rafters and provide a finished edge to the roof. 3. <strong>Soffit Profiles</strong>: Installed under the eaves to allow ventilation and conceal the underside of the roof. 4. <strong>Purlin Profiles</strong>: Support the roof sheeting and are placed perpendicular to the rafters. 5. <strong>Rafter Profiles</strong>: Mimic traditional wooden rafters and provide structural support. 6. <strong>Roof Ridge Profiles</strong>: Cap the ridge of the roof, where two slopes meet. 7. <strong>Hip and Valley Profiles</strong>: Used at the intersection of two sloping roof surfaces. Each profile is designed to withstand weather conditions and provide durability, with specific dimensions and shapes tailored to the roofing system's requirements.</p>

- Q: What is the price of aluminum paint spray?

- Powder mainly by tonnage count, usually 2-3 yuan / tonSpray painted mainly by area, usually 20-50 yuan / squareSpray paint depends on whether you want polyester or fluorocarbon, fluorocarbon expensive.

- Q: Is it possible to utilize recycled aluminum products as an alternative to new ones to decrease environmental impact and save costs?

- <p>Yes, using recycled aluminum products is an effective way to reduce environmental impact and cost. Recycling aluminum requires significantly less energy compared to producing new aluminum from raw materials, which reduces greenhouse gas emissions. Additionally, recycled aluminum retains the same properties as new aluminum, making it a viable alternative for many applications. This practice not only conserves resources but also lowers production costs, making it a sustainable choice for both the environment and your budget.</p>

- Q: What are the various materials that can be combined with aluminum profiles in construction or manufacturing?

- <p>Aluminum profiles can be combined with a variety of materials to enhance their functionality and durability. Common materials include steel for added strength, plastics for lightweight components, and various types of glass for transparency and aesthetics. They can also be paired with rubber or silicone seals for weatherproofing, and wood for a warmer, more natural aesthetic. Additionally, aluminum profiles are often used with other metals such as copper or brass for electrical conductivity or corrosion resistance. The choice of material depends on the specific application, desired properties, and design requirements.</p>

- Q: What is the difference between aluminum profile and sheet metal?

- Aluminum extrusions can be produced by extrusion or casting. In contrast, the aluminum sheet is flat, mainly for all types of surface.

- Q: How to distinguish aluminum alloy series?

- The classification of aluminum alloy profile series has different classification results according to different classification standards.First, the use can be divided into the following categories:1. doors and windows of the construction of aluminum windows and doors (divided into two types of doors and windows and curtain wall).2. aluminum alloy shelf aluminum profiles, they are different from the shape of the cross-section. But they are produced by hot extrusion.3. aluminum industry: mainly used in automation equipment, sealing cover skeleton and the custom mold machinery and equipment according to their own requirements, such as assembly line conveyor belt, hoisting machine, glue machine, testing equipment, electronic machinery industry and clean room with!Two, according to alloy classification:Can be divided into 1024, 2011, 6063, 6061, 6082, 7075 and other alloy grade aluminum profiles, of which the 6 series are the most common. Grades are different in various metal components ratio is not the same, except for the commonly used aluminum profile doors and windows such as the 60 series, 70 series, 80 series, 90 series, curtain wall series aluminum profile, aluminum industry has no clear distinction model, most manufacturers are in accordance with the actual processing of customer drawings.Three, according to surface treatment requirements classification:1. anodized aluminum2. electrophoresis coating aluminum material3. powder spraying aluminum material4. wood grain transfer aluminum5., light aluminum (divided into mechanical polishing and chemical polishing two), including chemical polishing costs

- Q: Can aluminum profiles be used for creating lighting fixtures?

- Indeed, lighting fixtures can be fashioned using aluminum profiles. The lightweight quality, durability, and resistance to corrosion render aluminum a favored material for such fixtures. Moreover, its malleability and feasibility for machining make it appropriate for crafting diverse designs and styles of lighting fixtures. Further, aluminum profiles can undergo powder coating or anodization to enrich their visual allure and furnish supplementary safeguard against deterioration. The adaptability and aesthetic charm of aluminum designate it as an optimal selection for producing lighting fixtures across an extensive array of environments, encompassing residential, commercial, and industrial settings.

- Q: How do you attach accessories or components to aluminum profiles?

- There are several ways to attach accessories or components to aluminum profiles. One common method is to use T-slot nuts and bolts. T-slot nuts slide into the T-slot groove on the profile and can be positioned anywhere along the length. The bolts then secure the accessory or component to the nut, creating a strong and secure connection. Another option is to use brackets or mounting plates specifically designed for aluminum profiles. These brackets usually have pre-drilled holes that align with the T-slot grooves, allowing for easy attachment of accessories. They can be fastened to the profile using screws or bolts. Additionally, there are various specialized connectors available for specific applications. Examples include corner connectors, joining plates, and hinge connectors. These connectors provide easy and reliable ways to attach accessories or components to aluminum profiles without the need for additional drilling or machining. It is important to consider the weight and load-bearing requirements of the accessories or components when choosing the attachment method. Using appropriate fasteners and connectors ensures a secure attachment and prevents any potential hazards.

- Q: This question asks for an explanation of the various techniques employed in the manufacturing process to create aluminum profiles.

- <p>Aluminum profiles are produced using several manufacturing methods, primarily including extrusion, casting, and rolling. Extrusion is the most common method, where aluminum is heated and forced through a die to take on a desired shape. Casting involves pouring molten aluminum into molds to create specific forms. Rolling is used to produce flat sheets or plates by passing aluminum between rollers. Other methods include forging, which shapes aluminum by applying compressive force, and machining, which involves cutting and shaping aluminum with tools. Each method has its applications depending on the desired profile shape, strength, and surface finish.</p>

Send your message to us

Solidworks Aluminum Weldment Profiles for Aluminum Window and Door Frame CNBM Hot Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.2

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords