Solidworks Aluminum Extrusion Profiles for Door and Window Frame

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Profile for Door and Window Frame Description:

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of the Aluminium Profile for Door and Window Frame:

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

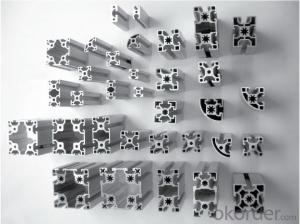

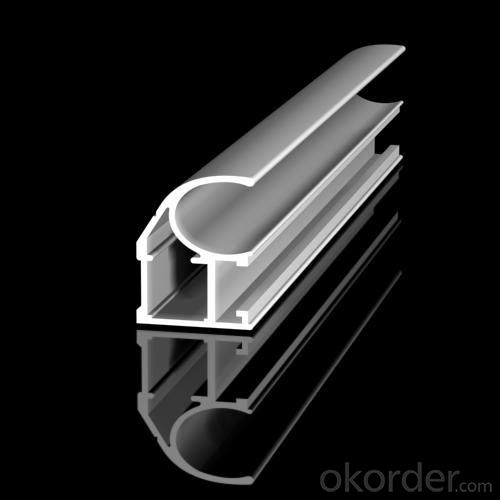

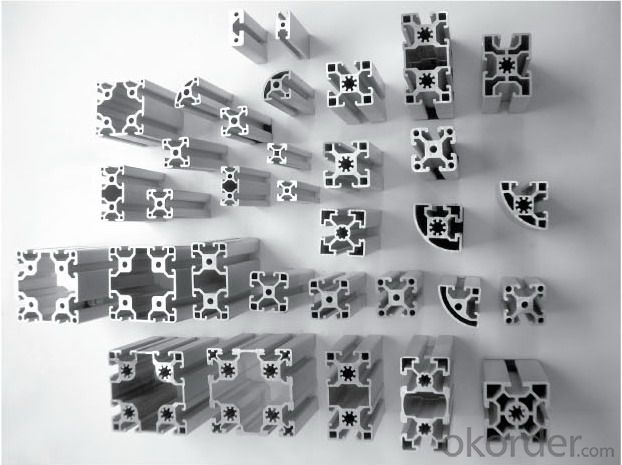

Images of the Aluminium Profile for Door and Window Frame:

Aluminium Profile for Door and Window Frame Specification:

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q: How do you prevent warping or distortion of aluminum profiles during fabrication?

- In order to prevent warping or distortion of aluminum profiles during fabrication, there are several key measures that can be implemented: 1. Storage in a controlled environment is crucial prior to fabrication. It is essential to store the aluminum profiles in an environment with stable temperature and humidity levels. This will help minimize any potential changes in the shape or dimensions of the metal. 2. Proper handling techniques must be employed to avoid bending or twisting the aluminum profiles. This includes using appropriate lifting equipment, avoiding excessive force, and ensuring even support during transportation. 3. During the fabrication process, it is important to utilize suitable machining techniques that minimize heat buildup. Excessive heat can cause the aluminum to expand and potentially warp. Utilizing cooling techniques such as lubricants or coolants can disperse heat and prevent distortion. 4. Controlled welding is crucial when working with aluminum profiles. Maintaining proper control over the welding process is essential. Employing appropriate welding techniques, such as preheating and post-weld heat treatment, can help minimize distortion. 5. Adequate fixturing methods should be employed during fabrication to ensure that the aluminum profiles are held in the correct position throughout the process. This prevents unintended bending or warping that could occur due to improper support or clamping. 6. Stress-relieving processes can be implemented after fabrication to minimize residual stresses within the aluminum profiles. This will prevent distortion or warping that may occur during subsequent handling or usage. 7. Regular inspection and measurement of the aluminum profiles during fabrication is necessary to identify any deviations from the desired specifications. This enables prompt corrective actions to be taken, reducing the risk of warping or distortion. By implementing these steps, manufacturers can significantly decrease the likelihood of warping or distortion in aluminum profiles during fabrication, ensuring the production of high-quality components or products.

- Q: The original aluminum is silver, but now the market has black, yellow and green, aluminum radiator, radiator is the color what are formed by oxidation of different colors, what are the benefits of it, are used in the above types of products?

- As for the coating and metal coating materials processing as the first surface degreasing and coarsening process, then spraying or cathodic electrophoresis mode is used in aluminum surface with a layer of film, choose different properties and color of paint can make the aluminum surface to obtain the corresponding protection performance.

- Q: This question asks for an overview of the various types of aluminum profiles that are typically utilized in construction projects.

- <p>Aluminum profiles used in construction come in various types, each serving specific purposes. Common types include: 1. Extruded Profiles: These are the most common, created by forcing aluminum through a die to achieve desired shapes. 2. Structural Profiles: Used for structural integrity in buildings, such as beams and columns. 3. Fa莽ade Profiles: Specifically designed for the exterior cladding of buildings. 4. Window and Door Profiles: For frame construction in windows and doors. 5. Fastening Profiles: Used for joining and fixing other aluminum components. 6. Special Profiles: Custom-made for unique applications. 7. Decorative Profiles: For aesthetic purposes, enhancing the appearance of structures. Each type has specific properties and is chosen based on the structural requirements and design considerations of the construction project.</p>

- Q: How can I distinguish the aluminum profiles in the building and the aluminum in the industry?

- Door frames, aluminum profiles and doors and windows, aluminum profiles are in the building. Your picture is a line of scaffold material, usually in industrial material.

- Q: What are the different surface treatment options available for aluminum profiles?

- Aluminum profiles offer a range of surface treatment options, each with its own advantages that enhance both appearance and performance. Let's explore some common treatments for aluminum profiles: 1. Anodizing: A widely used method, anodizing forms a protective oxide layer on the aluminum surface. This treatment provides excellent corrosion resistance, durability, and allows for a variety of color options. Architects, automotive manufacturers, and aerospace industries often rely on anodized aluminum profiles. 2. Powder coating: By applying a dry powder to the aluminum surface and curing it with heat, powder coating creates a tough and decorative layer. This treatment enhances durability, scratch resistance, and weatherability. The construction industry favors powder-coated aluminum profiles due to their appealing aesthetics and resistance to fading. 3. Electrophoretic coating: Also known as electrocoating or e-coating, this process immerses the aluminum profile in a paint bath while applying an electric current to evenly deposit paint particles. Electrophoretic coating offers excellent corrosion resistance, uniform thickness, and a smooth finish. It is commonly used in automotive and electronics manufacturing. 4. Mechanical finishing: To enhance appearance and smoothness, mechanical finishing techniques like brushing or polishing are employed. Brushing creates a brushed or satin finish, while polishing yields a mirror-like reflective surface. These finishes are often applied to decorative or architectural aluminum profiles. 5. Chemical etching: By selectively removing material using acid or a chemical solution, chemical etching can create decorative patterns, logos, or text on the aluminum surface. Various industries utilize chemical etching for branding or aesthetic purposes. 6. Plating: Plating involves depositing a thin layer of metal, such as chrome or nickel, onto the aluminum surface. This treatment enhances appearance, corrosion resistance, and wear resistance. Automotive, electronics, and decorative industries often make use of plated aluminum profiles. It's important to note that the choice of surface treatment depends on specific application requirements, such as aesthetics, durability, corrosion resistance, or conductivity. Consulting with professionals or suppliers can help determine the most suitable treatment option for aluminum profiles based on individual needs.

- Q: How is the price of aluminum profile calculated?

- The price is in accordance with the composition of aluminum ingot price plus processing fees in the form of the aluminum price is according to the informed price this is the South China Sea, the Internet can be found on the aluminum ingot prices every day is not the same, Saturday Sunday is not the price of aluminum ingot processing, to look at the cost of the products, aluminum price + welding rod cost the processing cost is + aluminum prices, profile surface treatment is not the same, the price is not the same

- Q: This question asks for the method to determine the amount of aluminum required for a construction project.

- <p>To calculate the weight of aluminum profiles needed for a building project, follow these steps: 1. Determine the length and cross-sectional area of each aluminum profile required. 2. Use the aluminum density, which is approximately 2.7 grams per cubic centimeter (g/cm鲁). 3. Multiply the volume (length 脳 cross-sectional area) by the density to get the weight of each profile. 4. Sum the weights of all profiles to get the total weight needed. Ensure to account for any additional material for joints, connections, and potential waste. It's also advisable to consult with an engineer or use specialized software for precise calculations tailored to your project's specific requirements.</p>

- Q: How do aluminum profiles perform in terms of sound insulation?

- Aluminum profiles generally have poor sound insulation properties compared to other materials such as wood or uPVC. This is because aluminum is a relatively lightweight and thin material, which allows sound waves to easily pass through it. Additionally, aluminum profiles often have a hollow structure, further reducing their ability to block or absorb sound. However, it is important to note that the overall sound insulation performance of a window or door system depends on various factors such as the thickness of the glass, the quality of the seals, and the installation method. To enhance the sound insulation capabilities of aluminum profiles, manufacturers may incorporate additional features like double or triple glazing, laminated glass, or acoustic seals. In conclusion, while aluminum profiles alone may not provide optimal sound insulation, they can be combined with other elements to improve their performance. If sound insulation is a significant concern, it is advisable to consider alternative materials that offer better inherent sound insulation properties.

- Q: Can aluminum profiles be painted or coated?

- Yes, aluminum profiles can be painted or coated.

- Q: This question asks for a list of various aluminum profiles that are specifically designed or used for roofing systems in regions with cold climates.

- <p>In cold climates, aluminum profiles for roofing systems are selected for their durability, strength, and resistance to harsh weather conditions. Common types include: 1. Standing Seam Profiles: These are popular for their weather-tightness and resistance to snow and ice. 2. Trapezoidal Profiles: Known for their strength and ability to handle heavy snow loads. 3. Box Rib Profiles: These provide excellent structural integrity and are suitable for areas with high wind uplift. 4. Snap-Lock Profiles: Easy to install and offer good resistance to snow and ice. 5. Corrugated Profiles: Provide a traditional look while being cost-effective and offering good drainage. 6. Panel Rib Profiles: These are designed for long spans and can withstand heavy snowfall. Each profile has specific applications and advantages, and the choice depends on the specific roofing requirements and local climate conditions.</p>

Send your message to us

Solidworks Aluminum Extrusion Profiles for Door and Window Frame

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords