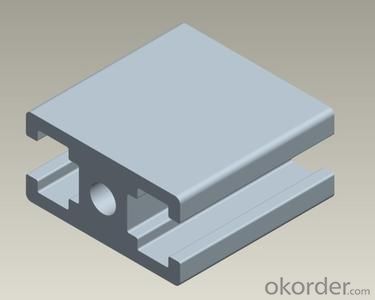

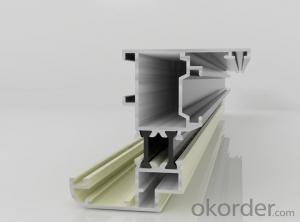

Aluminum Heat Sink Extrusion Profiles for Decoration

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetal with appearance ranging from silvery to dull gray,depending on the surface roughness. It is nonmagnetic and does not easilyignite. A fresh film of aluminium serves as a good reflector (approximately92%) of visible light and an excellent reflector (as much as98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffnessof steel. It iseasily machined,cast, drawn and extruded.

Alu Profile:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C at sight

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Guangzhou/Shenzhen port

4. Delivery time?

15-20 days after client’s deposit

- Q: How do I cut and shape aluminum profiles?

- In order to cut and shape aluminum profiles, one must possess several tools and techniques. Here is a step-by-step manual to aid you in accomplishing this task: 1. Obtain the required tools: A miter saw or a circular saw equipped with a carbide-tipped blade suitable for aluminum cutting is essential. Additionally, it is advisable to possess a metal file, sandpaper, a deburring tool, and a tape measure. 2. Measure and mark: Utilize a tape measure to determine the desired length of the aluminum profile. Indicate the location where the cut is to be made using a pencil or marker. 3. Secure the aluminum: Firmly place the aluminum profile on a workbench or cutting surface. Utilize clamps or a vice to hold it securely in place, ensuring it remains stationary during the cutting process. 4. Cut the aluminum: Position the saw blade at the marked location and align it perpendicular to the aluminum profile. Initiate the saw and gradually guide it through the aluminum, applying constant pressure. Allow the saw to perform the task without exerting excessive force, as excessive pressure may cause the blade to bind or chip. Exercise caution and wear safety goggles and gloves to shield yourself from any flying debris. 5. Smooth the edges: Following the cut, you may observe sharp or rough edges on the aluminum profile. Employ a metal file or sandpaper to level these edges, ensuring a clean and safe outcome. 6. Deburring: Employ a deburring tool to eliminate any burrs or rough spots remaining from the cutting process. Gently run the tool along the cut edges, applying slight pressure to smoothen them. 7. Shape the aluminum: If shaping the aluminum profile is necessary, numerous methods can be employed. A common technique involves clamping the profile to a workbench and gradually bending it using a hammer or rubber mallet. Alternatively, specialized tools such as a metal brake or bending machine can be utilized for more precise shaping. 8. Final touches: Once the aluminum profile has been cut and shaped, thoroughly clean it to eliminate any debris or metal shavings. Inspect the profile for any imperfections and make necessary adjustments before employing it for the intended application. Remember to exercise proper safety precautions throughout the process, including wearing safety goggles, gloves, and securely fastening the aluminum profile to prevent accidents.

- Q: How is the aluminum alloy profile series divided?

- According to alloy composition.1 pure aluminum, such as 1100,2 series aluminum alloy3 Series al Mn alloys, such as 3003, 3A214 series Al Si alloy5 Series Al Mg alloy6 series Al Mg Si alloy, such as 606360617 Series Al Zn Alloy8 lines, others9 line standby

- Q: The 50 series and the 60 series of aluminum profiles, which one is good?

- respectively60 of the cross section is larger than 50 1cm, much stronger. The glass gap that can be installed is also larger

- Q: This question asks for methods to ensure the reliable and durable installation of aluminum profiles.

- <p>To ensure the reliable and durable installation of aluminum profiles, follow these steps: Use high-quality aluminum materials that meet industry standards for strength and durability. Ensure proper alignment and level during installation to prevent warping or stress on the profiles. Use appropriate fasteners and adhesives recommended for aluminum to ensure a strong bond. Avoid over-tightening fasteners, which can cause deformation. Regularly inspect and maintain the profiles to check for signs of wear or damage, and address any issues promptly. This will help maintain the integrity and longevity of the aluminum profiles.</p>

- Q: This question asks for an overview of the various types of aluminum profiles that are typically utilized in construction projects.

- <p>Aluminum profiles used in construction come in various types, each serving specific purposes. Common types include: 1. Extruded Profiles: These are the most common, created by forcing aluminum through a die to achieve desired shapes. 2. Structural Profiles: Used for structural integrity in buildings, such as beams and columns. 3. Fa莽ade Profiles: Specifically designed for the exterior cladding of buildings. 4. Window and Door Profiles: For frame construction in windows and doors. 5. Fastening Profiles: Used for joining and fixing other aluminum components. 6. Special Profiles: Custom-made for unique applications. 7. Decorative Profiles: For aesthetic purposes, enhancing the appearance of structures. Each type has specific properties and is chosen based on the structural requirements and design considerations of the construction project.</p>

- Q: Aluminum profiles and plastic doors and windows which good, what market?

- Aluminum profiles and plastic doors and windows are not absolute, which is good or bad, each has its own advantages.1, Aluminum Alloy regular manufacturers are standard models of materials, thickness of 1.2 mm or more, and surface spraying or electrophoresis are very bright, the thickness of the coating is thick, make the effect and its performance are good. The insulation and heat insulation effect of the doors and windows made of plastic steel profiles and plastics are very good. Advantages: heat insulation, heat preservation, sound insulation, aging resistance, tightness2, plastic doors and windows using multi-layer sealing design, and type only smooth surface, not easy to adhesion dust, dirt, dustproof effect is excellent. Elegant and beautiful, plastic steel can be matched into a variety of colors.

- Q: Are there any special considerations for installing aluminum profiles?

- Yes, there are several special considerations for installing aluminum profiles. Firstly, it is important to ensure that the profiles are properly aligned and leveled during installation. This is crucial for achieving a seamless and professional-looking finished product. Using a laser level or a spirit level can help in this process. Secondly, it is essential to use the correct type and size of fasteners when installing aluminum profiles. Stainless steel or aluminum screws or rivets are commonly used, as they are resistant to corrosion and provide a secure hold. Additionally, it is important to pre-drill holes in the profiles to prevent cracking or splitting. Another consideration is the expansion and contraction of aluminum due to temperature changes. Aluminum has a high coefficient of thermal expansion, so it is necessary to leave enough space for the profiles to expand and contract without causing damage. This can be achieved by leaving a small gap between the profiles during installation. Furthermore, it is important to take into account the weight of the profiles and the load they will be subjected to. If the profiles are intended to support heavy loads or structural components, additional support or reinforcement may be required. Lastly, it is crucial to follow the manufacturer's instructions and guidelines for installation. Each type of aluminum profile may have specific requirements, such as recommended installation techniques or maximum spans between supports. Adhering to these guidelines will ensure a safe and secure installation. In conclusion, installing aluminum profiles requires careful attention to alignment, fasteners, expansion and contraction, load considerations, and following manufacturer's instructions. By considering these factors, one can ensure a successful and long-lasting installation.

- Q: Are aluminum profiles suitable for use in exterior wall insulation systems?

- <p>Yes, aluminum profiles can be used for exterior wall insulation systems. They are known for their durability, resistance to corrosion, and ability to withstand various weather conditions. Aluminum profiles provide a strong structural framework that can support insulation materials effectively. They are also lightweight, which makes them easy to handle and install. Additionally, aluminum profiles can be anodized or coated to enhance their resistance to environmental factors, making them a popular choice for exterior insulation systems.</p>

- Q: What are the noise insulation properties of aluminum profiles?

- Compared to other commonly used soundproofing materials like wood or PVC, aluminum profiles demonstrate relatively poor noise insulation properties. Due to its lightweight and thin nature, aluminum allows sound waves to effortlessly penetrate it. Consequently, it fails to offer a substantial obstacle for sound blocking or absorption, resulting in minimal noise reduction. Nevertheless, the noise insulation capabilities of certain aluminum profiles can be enhanced through the inclusion of insulating materials or the utilization of thicker profiles. While these adjustments can somewhat improve the soundproofing performance, they may still not match the effectiveness of materials specifically designed for noise insulation.

- Q: I would like to know where Urumqi has industrial aluminum profiles, such as 3030, 4040, 3060 aluminum, etc., note that industrial aluminum, not doors and windows, aluminum profiles, the difference between the two very large!

- And shares in the east railway station there, the east railway station and then go one Station Road (near the North Main Road) can see.

Send your message to us

Aluminum Heat Sink Extrusion Profiles for Decoration

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords