Anodized Aluminum Profiles for LED Strips of Good Quality

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminium Profile of Good Quality with Anodizing Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of theAluminium Profile of Good Quality with Anodizing:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

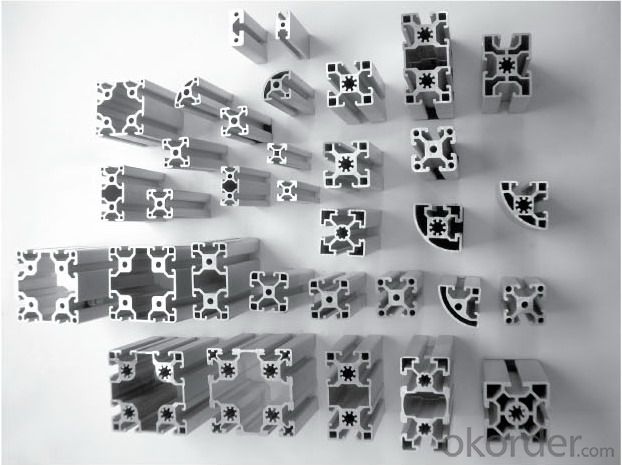

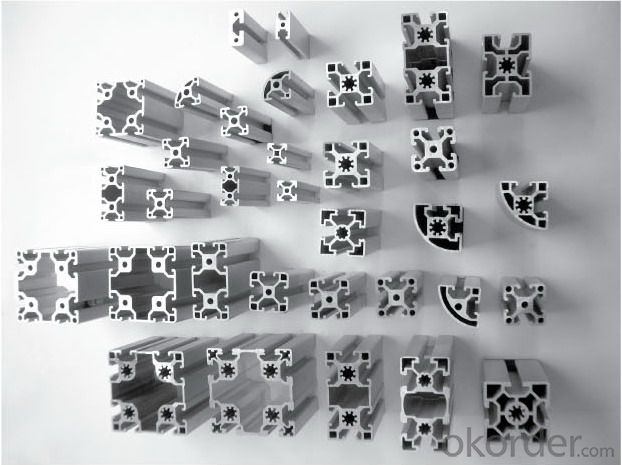

3.Aluminium Profile of Good Quality with Anodizing Images:

4.Aluminium Profile of Good Quality with AnodizingSpecification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the necessary upkeep and care procedures for aluminum profiles post-installation?

- <p>After installation, aluminum profiles generally require minimal maintenance due to their corrosion resistance and durability. However, regular cleaning to remove dust and dirt is recommended to maintain their aesthetic appeal and performance. This can be done using mild detergents and water. Periodic inspection for any signs of damage or wear is also important to ensure the structural integrity of the profiles. In case of any damage, it should be promptly attended to to prevent further deterioration. Despite their low maintenance nature, it's crucial to follow the manufacturer's guidelines for care and upkeep to prolong the life of the aluminum profiles.</p>

- Q: What are the factors involved in the selection of industrial aluminum profiles?

- Machinability: processability, package, formability, and machinability. Because of the formability and the state, in the selection of aluminum alloy brand, but also need to consider the range of various state of strength, usually the high strength of the material is difficult to shape. The platform should be bent, stretched, deep washed and so on. After finishing, the material has the best formability. On the contrary, the material in the heat treatment state has the worst formability. The cutting of the poor, Aluminum Alloy for molds, machinery parts need cutting better, on the other hand, the low strength of cutting is poor, the mold, machinery parts and other products need cutting, cutting Aluminum Alloy are important factors to consider.Weldability: the weldability of most aluminum alloys is no problem, especially Part 5 series aluminum alloy. It is specially designed for welding consideration. Relatively speaking, it is difficult to weld parts of the 2 and 7 series aluminum alloy.Decorative performance: aluminum used in decoration or some special occasions, need the anodic oxidation of the surface coating processing, to obtain the corresponding color and surface tissue, then the decoration should be a key consideration, in general, good corrosion resistance of the anode material, processing performance, surface treatment coating performance. The performance is very good.

- Q: Are aluminum profiles suitable for use in exterior insulation systems?

- <p>Yes, aluminum profiles can be used for exterior insulation systems. They offer high strength, durability, and resistance to weathering, making them ideal for external applications. Aluminum profiles are lightweight, easy to install, and can be used to create a robust framework for insulating materials, enhancing the energy efficiency and thermal performance of buildings.</p>

- Q: Can aluminum profiles be used in signage and display applications?

- Aluminum profiles are indeed applicable for signage and display purposes. With its lightweight and versatility, aluminum offers numerous advantages for these applications. Not only is it durable and resistant to corrosion, but it also has the ability to withstand various weather conditions, making it suitable for both indoor and outdoor use. Furthermore, aluminum profiles can be easily customized in terms of shape, size, and finish, enabling the creation of distinctive and captivating signs and displays. Additionally, the convenience of assembling and disassembling aluminum profiles makes transportation and installation hassle-free. In conclusion, aluminum profiles offer an excellent solution for signage and display applications due to their resilience, adaptability, and visual appeal.

- Q: This question asks about the various finishing options that can be applied to aluminum profiles.

- <p>Aluminum profiles can be finished in several ways to enhance their appearance and durability. Common types of finishes include: 1. Anodizing, which provides a protective oxide layer and can be colored. 2. Powder coating, a durable and customizable finish that offers a wide range of colors and textures. 3. Electrophoretic coating, which results in a smooth, even finish and is often used for automotive parts. 4. Polishing, which can produce a mirror-like finish. 5. Brushing, which creates a鍝戝厜 texture with a satin-like appearance. 6. Painting, which can be done with solvent-based or water-based paints for a variety of color options. 7. Wood grain transfer, which gives aluminum profiles the appearance of wood. Each finish has its own advantages and is chosen based on the specific application and aesthetic requirements.</p>

- Q: Are aluminum profiles resistant to chemicals or solvents?

- Yes, aluminum profiles are generally resistant to chemicals and solvents. Due to their natural oxide layer, they exhibit good corrosion resistance and can withstand exposure to many common chemicals and solvents without significant degradation or damage. However, it is important to note that the specific resistance may vary depending on the type of chemical or solvent involved, concentration, temperature, and exposure duration.

- Q: How to calculate the spraying powder of aluminium profile?

- Powder consumption is calculated according to the thickness of the coating film, powder density according to 1.2-1.6g/ cm fand effective coating rate of 50-70% formula, don't I teach.

- Q: How do you join two aluminum profiles together?

- To achieve the desired strength, appearance, and functionality of a joint between two aluminum profiles, there are multiple techniques available. Here are a few commonly employed methods: 1. Utilizing Mechanical Fasteners: One straightforward and widely used approach is to employ mechanical fasteners like screws, bolts, or rivets. These fasteners can be drilled through both profiles and tightened to securely connect them. The selection of the appropriate size and type of fastener should be based on the profiles' thickness and material. 2. Employing Welding: Welding is another popular means of joining aluminum profiles. It involves melting the aluminum at the joint and allowing it to solidify, creating a strong bond between the profiles. Different welding techniques, such as TIG (Tungsten Inert Gas) welding and MIG (Metal Inert Gas) welding, can be utilized depending on the specific application and requirements. 3. Implementing Adhesives: Adhesive bonding provides a non-intrusive method for connecting aluminum profiles. Specially formulated adhesives designed for aluminum bonding can be applied to the profile surfaces and then pressed together. This type of joint is particularly advantageous when a seamless appearance is desired, as it eliminates the need for visible fasteners or welds. However, the strength of the adhesive bond may vary depending on the adhesive type. 4. Employing Interlocking Systems: Certain aluminum profiles are designed with interlocking systems that allow for easy connection. These systems typically involve the use of connectors or accessories specifically designed for the given profiles. They can deliver a secure and sturdy joint while also simplifying the assembly process. When choosing the appropriate method to join two aluminum profiles, it is vital to consider factors such as strength requirements, aesthetics, ease of assembly, and the potential need for disassembly. Additionally, consulting professionals or experts in aluminum fabrication is recommended to ensure the chosen method suits the specific application.

- Q: Can aluminum profiles be used in the manufacturing of furniture?

- Furniture production can utilize aluminum profiles, which are versatile and lightweight materials. Aluminum possesses numerous advantages for furniture manufacturing, such as durability, corrosion resistance, and a high strength-to-weight ratio. Due to these properties, it is suitable for various furniture applications, including chairs, tables, shelving units, and frames. Moreover, aluminum profiles offer easy customization, enabling the creation of distinctive and contemporary designs. By incorporating aluminum into furniture manufacturing, sustainability is promoted as it is a recyclable material. In conclusion, aluminum profiles offer flexibility and durability to designers and manufacturers, rendering them a favored option in the furniture industry.

- Q: How do aluminum profiles perform in blast-resistant structures?

- Aluminum profiles are widely used in blast-resistant structures due to their exceptional performance characteristics. These profiles offer several advantages that make them suitable for such applications. Firstly, aluminum profiles possess excellent strength-to-weight ratio, which allows them to provide high structural integrity while keeping the overall weight of the structure relatively low. This is crucial in blast-resistant structures as it helps to minimize the impact of an explosion and reduce potential damage. Furthermore, aluminum profiles exhibit remarkable corrosion resistance, making them highly durable in harsh environments. This is particularly important in blast-resistant structures, where exposure to intense pressure waves, debris, and extreme temperatures may occur during an explosion. Moreover, aluminum profiles have excellent energy absorption capabilities. They can effectively absorb and dissipate the energy generated by a blast, thereby reducing the impact on the structure and enhancing its overall blast resistance. This feature is essential in ensuring the safety of occupants and preventing structural failure. Additionally, aluminum profiles offer excellent design flexibility, allowing architects and engineers to create complex and innovative structures. This versatility enables the construction of blast-resistant structures that can be tailored to specific requirements and design constraints. In summary, aluminum profiles perform exceptionally well in blast-resistant structures due to their high strength-to-weight ratio, corrosion resistance, energy absorption capabilities, and design flexibility. These qualities make them a preferred choice for architects and engineers when designing structures that need to withstand the forces generated by an explosion.

Send your message to us

Anodized Aluminum Profiles for LED Strips of Good Quality

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords