Extrusion Profiles Aluminum Coil in Accordion to European Standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Coil in Acoording to Europ Standard Description:

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of the Aluminium Coil in Acoording to Europ Standard Applications:

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

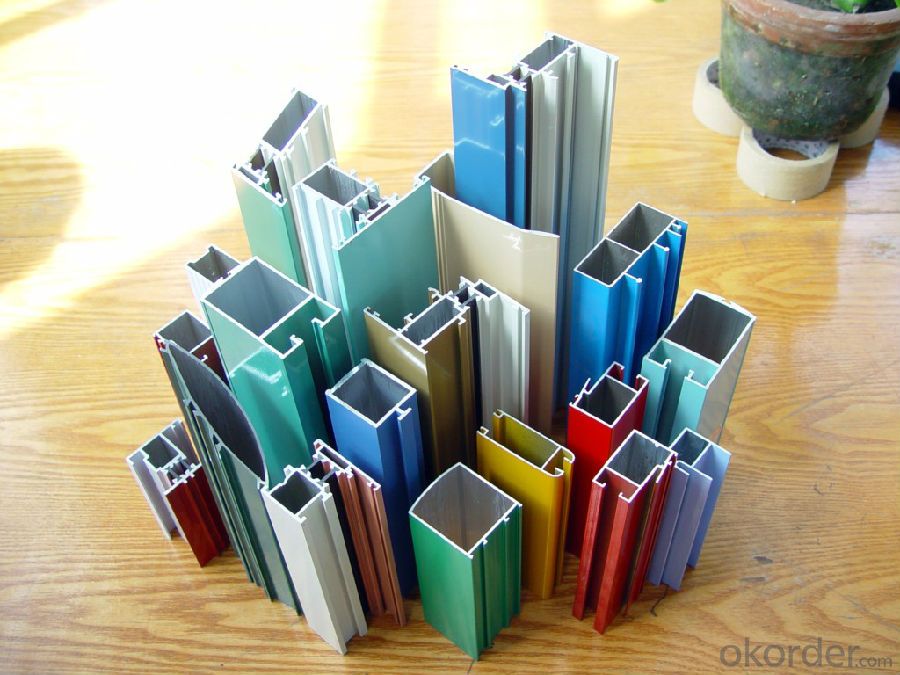

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

Images of the AAluminium Coil in Acoording to Europ Standard:

AAluminium Coil in Acoording to Europ Standard Specification:

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q: How is the aluminum alloy profile series divided?

- According to alloy composition.1 pure aluminum, such as 1100,2 series aluminum alloy3 Series al Mn alloys, such as 3003, 3A214 series Al Si alloy5 Series Al Mg alloy6 series Al Mg Si alloy, such as 606360617 Series Al Zn Alloy8 lines, others9 line standby

- Q: What are the different bending options available for aluminum profiles?

- There are several bending options available for aluminum profiles, depending on the specific requirements and desired outcomes. Some of the common bending methods for aluminum profiles include: 1. Roll Bending: This method involves passing the aluminum profile between a series of rollers to achieve the desired bend. Roll bending is typically used for larger and thicker profiles, as it provides a gradual and consistent bend. 2. Press Bending: Press bending uses a hydraulic or mechanical press to apply force and shape the aluminum profile into the desired form. This method is suitable for both small and large profiles and can achieve various bend angles. 3. Mandrel Bending: Mandrel bending involves inserting a mandrel, which is a rod or tube, into the aluminum profile to maintain its shape during the bending process. This method ensures precise and uniform bends, making it suitable for complex shapes and tight radius bends. 4. Stretch Bending: Stretch bending applies controlled stretching forces to the aluminum profile, allowing it to flex and bend. This method is often used for profiles with large radii and gentle curves. 5. Rotary Draw Bending: Rotary draw bending utilizes a die and a rotating arm to bend the aluminum profile around a specific radius. This method is highly accurate and commonly used for precise and repeatable bends. 6. Heat Bending: Heat bending involves applying heat to the aluminum profile to soften it before bending. Once the desired bend is achieved, the profile is cooled to retain its new shape. This method is suitable for profiles with complex shapes and sharp angles. Each bending option has its advantages and limitations, and the selection depends on factors such as the profile size, shape complexity, bend angle, and required precision. Consulting with a professional or a bending specialist is recommended to determine the most appropriate bending method for specific aluminum profile applications.

- Q: How do aluminum profiles contribute to lightweight construction?

- Due to their inherent properties and versatile applications, aluminum profiles play a crucial role in the field of lightweight construction. Firstly, aluminum, being a lightweight material, has a density that is roughly one-third of that of steel. This implies that using aluminum profiles instead of heavier materials like steel or concrete aids in minimizing the overall weight of the structure or product. The lightweight nature of aluminum profiles presents several advantages in the construction industry. One notable benefit is the ease of handling and installation, which reduces the reliance on heavy machinery and labor-intensive processes. Consequently, this not only enhances the efficiency of construction projects but also leads to cost reductions. Furthermore, the utilization of aluminum profiles in lightweight construction contributes to energy efficiency. Aluminum is an excellent conductor of heat and electricity, allowing for effective heat dissipation and decreased energy consumption in buildings. This property is particularly advantageous in the construction of energy-efficient buildings, aligning with sustainability objectives. Another aspect in which aluminum profiles contribute to lightweight construction is their exceptional strength-to-weight ratio. In spite of their lightweight nature, aluminum profiles possess high tensile strength, making them highly durable and capable of withstanding various loads and stresses. This characteristic enables the creation of robust and stable structures while minimizing the use of materials. Moreover, aluminum profiles offer design flexibility and versatility. They can be extruded into various shapes and sizes, empowering architects and designers to conceive intricate and innovative structures. The ability to customize profiles according to specific project requirements enhances the architectural possibilities in lightweight construction. Additionally, aluminum profiles exhibit corrosion resistance, significantly extending their lifespan and reducing maintenance costs. This makes them suitable for applications in diverse climates and environments, including coastal regions where saltwater corrosion is prevalent. In conclusion, aluminum profiles contribute to lightweight construction by reducing overall weight, enhancing energy efficiency, providing strength and durability, offering design flexibility, and ensuring corrosion resistance. These factors establish aluminum profiles as a preferred choice in a wide array of construction projects, ranging from residential buildings to large-scale infrastructure.

- Q: What are the advantages of industrial aluminum profiles? What are the problems that should be paid attention to?

- Among a large number of aluminum processing materials, a large number of international advanced products and national famous brand products have emerged, representing the mainstream of the development and application of modern aluminum processing technology in china.

- Q: Is it possible to recycle aluminum profiles and use them again in construction projects?

- <p>Yes, aluminum profiles can be recycled and reused in construction. Aluminum is highly recyclable, and the recycling process requires significantly less energy compared to the production of new aluminum. Recycled aluminum maintains its properties, making it suitable for various construction applications. This practice not only conserves resources but also reduces waste and environmental impact.</p>

- Q: What are the different cutting options available for aluminum profiles?

- Aluminum profiles have various cutting options to choose from, depending on the project's specific requirements. Some commonly used cutting methods include: 1. Miter Saw: A popular choice for aluminum profiles, the miter saw utilizes a circular blade to make precise angled cuts, ensuring accuracy and cleanliness. 2. Chop Saw: Similar to the miter saw, the chop saw is also frequently employed for cutting aluminum profiles. It effortlessly creates straight cuts at 90-degree angles, making it efficient and capable of handling larger profiles. 3. Bandsaw: Offering versatility, the bandsaw utilizes a continuous looped blade to make straight cuts. It provides flexibility in terms of cutting angles and can handle thicker aluminum profiles. 4. CNC Cutting: Renowned for its precision, CNC cutting involves the use of a computer-controlled cutting machine that can follow intricate design patterns. This method is ideal for detailed and intricate cuts, guaranteeing high precision and repeatability. 5. Laser Cutting: Laser cutting is a popular choice due to its high precision and ability to create clean cuts. By using a focused laser beam to melt or vaporize the aluminum, laser cutting ensures smooth and accurate results. It is suitable for both simple and complex designs. 6. Waterjet Cutting: Waterjet cutting is a versatile method that employs a high-pressure jet of water mixed with abrasive particles to cut through aluminum profiles. It can handle various thicknesses and shapes, providing precise cuts without altering the properties of the aluminum or generating heat. 7. Shearing: A basic yet effective cutting method, shearing involves using sharp blades to trim or cut aluminum profiles. It is commonly used for straight cuts and is suitable for thinner profiles. 8. Plasma Cutting: Plasma cutting employs a high-velocity jet of ionized gas to cut through aluminum profiles. It is suitable for thicker profiles and allows for faster cutting speeds compared to other methods. These are just a few of the cutting options available for aluminum profiles. The choice of method depends on factors such as desired cut type, accuracy requirements, profile thickness, and design complexity. It is crucial to consider these factors and seek professional consultation to determine the most suitable cutting option for a specific project.

- Q: The 50 series and the 60 series of aluminum profiles, which one is good?

- respectively60 of the cross section is larger than 50 1cm, much stronger. The glass gap that can be installed is also larger

- Q: Acrylic coating principle, coating on the aluminum section, he and fluorocarbon powder spraying, what is the difference

- Compared with the other two spraying methods, the best quality, the most beautiful appearance, but the price is expensive, not green. Used in high-end buildings, commercial building more

- Q: Can aluminum profiles be used in the production of audiovisual equipment?

- Yes, aluminum profiles can be used in the production of audiovisual equipment. Aluminum is a lightweight and durable material that can be easily molded into various shapes and designs. It offers excellent heat dissipation properties and is resistant to corrosion, making it suitable for audiovisual equipment such as speaker stands, camera mounts, and TV brackets. Additionally, aluminum profiles can be customized to fit specific requirements, providing flexibility in design and construction.

- Q: This question asks about the impact of aluminum profiles on the thermal efficiency of a building.

- <p>Aluminum profiles can significantly affect the thermal performance of a building. They are excellent conductors of heat, which means they can transfer heat quickly. This property can be both advantageous and disadvantageous. On the positive side, aluminum profiles can help dissipate heat from the building, reducing the need for air conditioning. However, they can also lead to heat loss in colder climates, reducing the building's energy efficiency. To mitigate this, thermal breaks are often incorporated into aluminum profiles to reduce heat transfer. Additionally, insulating materials can be used alongside aluminum profiles to enhance the building's thermal insulation. Proper design and material selection are crucial to optimize the thermal performance of a building with aluminum profiles.</p>

Send your message to us

Extrusion Profiles Aluminum Coil in Accordion to European Standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords