Led Strip Channels Aluminum Profiles for Windows and Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Aluminum profile

1. Brand: Bright Star

2. Place of origin: Guangdong, China

3. Temper: T5/T6

4. Grade: 6000 S

Goldsword Aluminum Factory | |

Business Type | Aluminum profile Manufacturer |

Product series | aluminum profile for window and doors |

Price Determination | Based on Aluminum Ingot Price + Process fee |

Payment Term | T/T, L/C at sight |

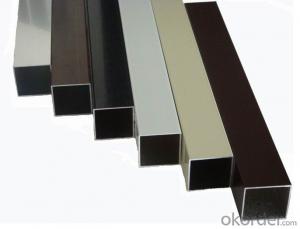

Surface Treatment | We can provide aluminum profiles with mill finish, powder coating, anodizing, polishing, sand blasting, electrophoresis and wood color. |

Color | We can provide white, wood color, black, golden, blue, champagne, and other colors as required. |

Packing | Composite paper, Plastic paper, other packing method required by customers is available. 2 to 20 pcs per bundle, sometimes small profiles are plugged in big ones so as to save space for customers. |

Product specification | 1. Alloy: 6063-T5/T6 2. Length: 3-6.5 m 3. Normal anodizing thickness: 8 to 12 micro 4. Normal powder coating thickness: 60 – 100 micro 5. Tensile Strength: ≥160 MPa 6. Yield strength: ≥110 MPa 7. Extensibility: ≥8% 8. Hardness (HW): ≥8 |

- Q: How can the aluminum profile T6 and T5 be distinguished?

- Mechanical properties are inconsistent, T5 tensile strength is 160 MPa; T6 tensile strength is 215 mpa. (normally determined by this method) do a tensile test and you'll see

- Q: Can aluminum profiles be cut to size?

- Yes, aluminum profiles can be cut to size. Aluminum profiles are typically manufactured in standard lengths and can be easily cut to the desired length or size using various cutting methods such as sawing, shearing, or CNC machining. This allows for customization and flexibility in using aluminum profiles for different applications.

- Q: Where is the aluminum profile market in Tianjin?

- Fen Shui Dao aluminum tube, aluminum strip,,,Tianjin Hongyuan Aluminum Co. ltd..Main business products: industrial aluminum series and its accessories, aluminum accessories, aluminum frame, table, line, standard, European standard and non-standard aluminum industrial profiles and accessories, free drawings analysis, drawing and mold production, a series of industrial aluminum frame, assembly line etc..

- Q: Can aluminum profiles be used in the production of packaging materials?

- Aluminum profiles have the capability to be utilized for the creation of packaging materials. Renowned for its durability, lightweight nature, and strength, aluminum is an excellent selection for packaging applications. These profiles can be extruded into diverse shapes and sizes, accommodating personalized packaging solutions. They can be employed to fabricate packaging containers, like cans, bottles, and tubes, which are commonly utilized for food, beverages, pharmaceuticals, cosmetics, and various other consumer goods. The utilization of aluminum profiles in packaging materials presents numerous benefits, such as resistance to corrosion, impermeability to light, oxygen, and moisture, as well as ease of molding and printing. Furthermore, aluminum is a fully recyclable material, rendering it an environmentally conscious choice for packaging production. Ultimately, aluminum profiles serve as a dependable and effective alternative for the manufacturing of packaging materials.

- Q: How do aluminum profiles perform in terms of static electricity discharge?

- Aluminum profiles possess exceptional properties for discharging static electricity. By virtue of their high electrical conductivity, aluminum profiles effectively dissipate static charges that might accumulate on their surface. This aids in the prevention of static electricity buildup, a matter of great significance in industries where electrostatic discharge can endanger sensitive electronic components or pose safety hazards. The conductivity of aluminum profiles facilitates the convenient grounding of any static charges, thereby ensuring a safe working environment. Additionally, aluminum profiles frequently find application in the construction of ESD protective equipment and structures, further underscoring their efficacy in managing static electricity. All in all, aluminum profiles offer utmost reliability in terms of static electricity discharge, rendering them a preferred choice in various industries necessitating static control.

- Q: What are the industries that require aluminum profiles in industry?

- 10, furniture aluminum profiles are mainly used for furniture decorative boxes, tables and chairs, support components11, solar photovoltaic solar energy profiles include: aluminium frame, solar photovoltaic, solar photovoltaic and other fastener scaffold.12, rail vehicle structure aluminum alloy profile: mainly used for rail vehicle body manufacturing. Aluminum alloy profiles have the characteristics of light weight, good formability, high strength, corrosion resistance and recycling. In recent years, aluminum and aluminum alloys have been used more and more widely in the field of rail vehicles.13, Mount Aluminum Profiles: made of aluminum alloy frame, mounting a variety of exhibitions, decorative paintings.14, medical equipment aluminum profile is mainly used in: stretcher frame, medical equipment, medical bed, etc..

- Q: Can aluminum profiles be used in the production of transportation containers?

- Yes, aluminum profiles can be used in the production of transportation containers. Aluminum is a lightweight and durable material that is widely used in various industries, including transportation. It offers several advantages for container production, such as corrosion resistance, high strength-to-weight ratio, and ease of fabrication. Aluminum profiles can be used to construct the framework and walls of transportation containers, providing structural integrity while keeping the overall weight of the container low. Additionally, aluminum profiles can be easily customized and shaped to fit specific container requirements. Overall, the use of aluminum profiles in transportation container production offers numerous benefits and is a popular choice among manufacturers.

- Q: How is the thickness of the base plate of the aluminum profile radiator calculated? Are there formulas for calculation?

- There should be empirical formula, the heat of the surface heat dissipation is related to thermal conductivity, thickness, temperature change, surface area. Then the best thickness is calculated by linear programming.

- Q: What are the advantages and disadvantages of the use of magnesium profiles compared with aluminum profiles?

- 3 oxidation of metals: the periodic table clearly shows that magnesium alloy is more easily oxidized than aluminum alloy.4 manufacturing cost Description: because magnesium alloy is a lively metal, so manufacturing equipment and environment have higher requirements, leading to high manufacturing costs, production of bicycle frame cost performance is far less than aluminum alloy frame.

- Q: Can aluminum profiles be used in the production of automotive interiors?

- Yes, aluminum profiles can be used in the production of automotive interiors. Aluminum profiles offer lightweight, durable, and corrosion-resistant properties, making them suitable for various interior components such as door panels, dashboard trims, seat frames, and console accents. Additionally, aluminum profiles can be easily customized and integrated with other materials, allowing for innovative designs and improved functionality in automotive interiors.

Send your message to us

Led Strip Channels Aluminum Profiles for Windows and Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords