Custom Aluminum Profiles for Aluminium Profile of Casting Material for Windows

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminium Profile of Casting Material for Windows Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminium Profile of Casting Material for Windows:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

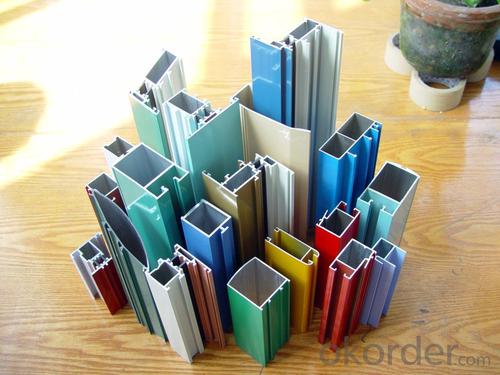

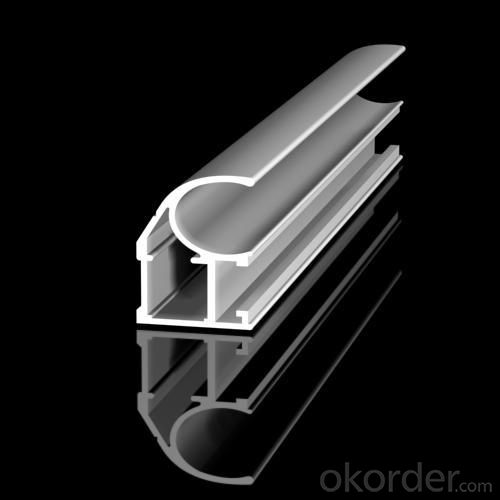

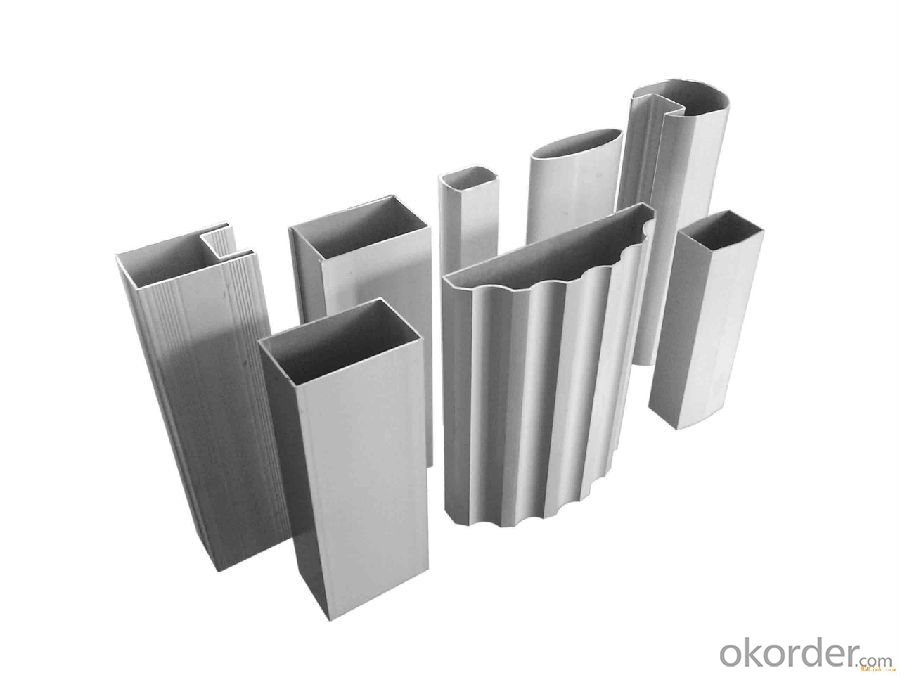

3.Aluminium Profile of Casting Material for Windows Images:

4.Aluminium Profile of Casting Material for Windows Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Are aluminum profiles suitable for constructing interior partitions or ceilings in commercial buildings?

- <p>Yes, aluminum profiles are commonly used for interior partitions and ceilings in commercial buildings. They offer several advantages such as strength, durability, and resistance to corrosion. Aluminum profiles are lightweight, easy to install, and can be custom designed to fit specific architectural requirements. They also provide good thermal insulation and can be used in both new constructions and renovations.</p>

- Q: Are aluminum profiles suitable for use in the electronics industry?

- The electronics industry finds aluminum profiles to be a suitable option. Aluminum, being lightweight, durable, and resistant to corrosion, becomes an excellent choice for different electronic applications. Its exceptional thermal conductivity facilitates efficient dissipation of heat in electronic devices, which is crucial to avoid overheating and ensure optimal performance. Moreover, aluminum profiles can be easily customized and fabricated to fulfill specific design requirements, making them adaptable for various electronic components and enclosures. They also possess electromagnetic shielding properties, safeguarding sensitive electronic circuits from interference. All in all, aluminum profiles provide numerous advantages for the electronics industry, making them a popular and appropriate option for electronic devices and equipment.

- Q: The latest list of aluminum China

- Lear aluminum is also good Oh, A Well-Known Trademark in China, China energy-saving innovation enterprise ten, Hebei enterprises in Handan

- Q: What are the potential hazards or risks associated with the use of aluminum profiles in construction projects?

- <p>Safety concerns related to using aluminum profiles in construction include potential corrosion due to exposure to harsh weather conditions, risk of electrical conductivity which may lead to electrocution hazards, and the possibility of thermal expansion and contraction causing structural instability. Additionally, improper installation can lead to structural failure, and the lightweight nature of aluminum may not provide sufficient strength in load-bearing applications. It's crucial to ensure proper design, quality materials, and adherence to safety standards to mitigate these risks.</p>

- Q: Are there various ways to install aluminum profiles?

- <p>Yes, aluminum profiles can be installed using different methods. Common installation techniques include direct fastening with screws or bolts, using adhesives or sealants, and employing clip or channel systems. The choice of method depends on the specific application, load-bearing requirements, and aesthetic considerations. Some methods may provide quicker installation, while others might offer better structural integrity or visual appeal. It's important to consult with a professional or follow manufacturer guidelines to ensure the proper installation method is used for the intended application.</p>

- Q: Are aluminum profiles suitable for exhibition displays?

- Yes, aluminum profiles are highly suitable for exhibition displays. They are lightweight, durable, and can be easily customized to fit various display requirements. Aluminum profiles also offer a sleek and modern aesthetic, making them ideal for creating visually appealing exhibition displays. Additionally, they are versatile and can be easily assembled and disassembled, allowing for easy transportation and setup at different exhibition venues.

- Q: Can aluminum profiles be used in the construction of greenhouses?

- Yes, aluminum profiles can be used in the construction of greenhouses. Aluminum is a lightweight and durable material, making it an excellent choice for greenhouse construction. It is resistant to corrosion, which is important in a moist and humid environment like a greenhouse. Aluminum profiles can be easily fabricated and assembled, allowing for flexibility in design and construction. Additionally, aluminum is a sustainable material as it is 100% recyclable, making it environmentally friendly for greenhouse construction. Overall, aluminum profiles are a practical and reliable option for building greenhouses.

- Q: What are the different extrusion processes used for aluminum profiles?

- Aluminum profiles can be produced using various extrusion processes, each with its own advantages and applications. The most commonly used processes for aluminum profiles are as follows: 1. Direct extrusion: This process involves forcing a heated aluminum billet through a die to form the desired shape. It is widely used and efficient, offering cost-effectiveness and the ability to produce profiles with consistent cross-sections, ranging from simple to complex. 2. Indirect extrusion: In this process, the billet remains stationary while the die moves, pushing the aluminum through the die to create the profile. Indirect extrusion is preferred when intricate internal features, higher surface finish, and tighter tolerances are required. 3. Impact extrusion: Specialized in creating hollow aluminum profiles like tubes or containers, impact extrusion involves placing an aluminum slug in a die and driving a punch into it. The slug flows around the punch to form the desired shape, making it suitable for thin-walled profiles with complex shapes. 4. Hydrostatic extrusion: This cold extrusion process utilizes high-pressure liquid to force the aluminum billet through a die. It is commonly used for producing high-strength profiles with improved mechanical properties and dimensional accuracy. 5. Hot extrusion: The aluminum billet is heated above its recrystallization point and then forced through a die in hot extrusion. This process is ideal for complex-shaped profiles, as the elevated temperature allows for better material flow and deformation. Each extrusion process offers unique benefits and is selected based on the specific requirements of the aluminum profile. Factors such as shape, complexity, surface finish, tolerances, and mechanical properties all play a crucial role in determining the most suitable extrusion process.

- Q: Are aluminum profiles suitable for use in the construction of high-rise buildings?

- <p>Yes, aluminum profiles can be used in high-rise buildings. They are known for their high strength-to-weight ratio, which makes them ideal for structural applications where weight is a concern. Aluminum profiles are also resistant to corrosion and can withstand harsh weather conditions, making them a popular choice for exterior applications. Additionally, their recyclability and sustainability make them an environmentally friendly option. However, it's important to ensure that the aluminum profiles meet the specific load-bearing requirements and safety standards for high-rise construction.</p>

- Q: This question asks about the various methods employed in the production of aluminum profiles, which are long, extruded shapes made from aluminum.

- <p>Aluminum profiles are manufactured using several processes, primarily extrusion, which involves forcing aluminum through a die to create specific shapes. Other processes include casting, where aluminum is poured into molds, and rolling, used to create flat sheets or plates. Machining processes like cutting, drilling, and milling are also used for further shaping and finishing. Additionally, aluminum profiles can be fabricated through bending, which shapes the material into curves or angles, and welding, which joins pieces together. Surface treatments like anodizing, painting, or powder coating are also applied to enhance appearance and durability.</p>

Send your message to us

Custom Aluminum Profiles for Aluminium Profile of Casting Material for Windows

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords