All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the measures for recycling and reusing aluminum profiles in infrastructure projects and sustainable urban planning?

There are several measures that can be implemented to promote recycling and reuse of aluminum profiles in infrastructure projects and sustainable urban planning.

1. Collection and separation: Establishing a systematic collection and separation process for aluminum profiles at construction sites and urban areas can ensure proper recycling and reuse. This can involve setting up dedicated containers or bins for aluminum profiles, making it easier for contractors and individuals to dispose of them separately.

2. Recycling facilities: Developing recycling facilities specifically for aluminum profiles can help in effectively processing and reusing the material. These facilities should have the necessary equipment and technology to efficiently extract aluminum from profiles and convert them into new products or components.

3. Awareness and education: Raising awareness among stakeholders, including architects, engineers, contractors, and residents, about the benefits and importance of recycling and reusing aluminum profiles is crucial. Educating them about the environmental impact of aluminum extraction and production, as well as the potential savings and resource conservation through recycling, can encourage their active participation.

4. Design for disassembly: Encouraging the design of infrastructure and urban projects with disassembly in mind can facilitate the reuse of aluminum profiles. By considering the ease of dismantling and separating aluminum profiles during the design phase, it becomes feasible to salvage and reuse them in future construction or retrofitting projects.

5. Incentives and regulations: Governments and local authorities can play a significant role by implementing incentives or regulations to promote the recycling and reuse of aluminum profiles. This can include financial incentives for contractors or developers who prioritize recycling, or incorporating requirements for the use of recycled aluminum profiles in infrastructure projects.

Overall, by implementing these measures, we can enhance the circular economy approach, reduce waste, and promote the sustainable use of aluminum profiles in infrastructure projects and urban planning.

What are the key differences between aluminum profiles and aluminum sheets in terms of applications?

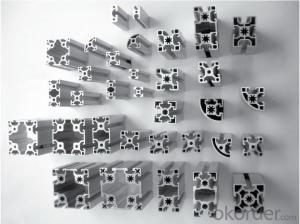

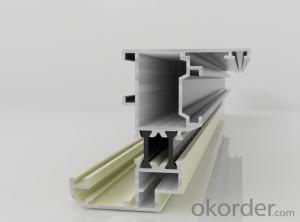

The key differences between aluminum profiles and aluminum sheets in terms of applications lie in their respective shapes and structural properties. Aluminum profiles are typically extruded into various shapes, such as beams, channels, or angles, making them suitable for structural applications where strength and load-bearing capabilities are required. They are commonly used in construction, automotive, aerospace, and machinery industries.

On the other hand, aluminum sheets are flat and thin, often used for surface applications, such as cladding, roofing, or decorative purposes. They are versatile and can be easily cut, bent, or formed into different shapes, making them suitable for a wide range of applications including signage, food packaging, electronics, and transportation.

Overall, while aluminum profiles excel in structural strength and support, aluminum sheets offer flexibility and aesthetic appeal, making them ideal for surface applications.

How do you clean and maintain aluminum profiles?

To clean and maintain aluminum profiles, start by removing any loose dirt or debris using a soft brush or cloth. Then, mix a mild detergent with warm water and use a sponge or cloth to gently scrub the surface of the profiles. Rinse thoroughly with clean water and dry with a soft towel to prevent water spots. For regular maintenance, wipe the profiles with a damp cloth to remove any dust or grime. Avoid using abrasive cleaners or materials that can scratch the surface of the aluminum.

Wholesale Aluminum Profiles from supplier in Panama

We are confident that our extensive range of Aluminum Profiles in Panama, combined with our expertise and commitment to customer satisfaction, will meet and exceed your expectations. Whether you are looking for standard profiles or customized solutions, we have the knowledge and resources to deliver the best results for your projects.

Our team of professionals is dedicated to providing you with seamless procurement services, from sales and quotations to technical support. We understand the unique requirements and challenges of the Panama market, and we are well-prepared to offer valuable insights and assistance throughout the process.

With our strong partnership with CNBM, a Fortune Global 500 company, we have access to a wide range of high-quality products and resources. This enables us to provide you with competitive prices, timely delivery, and excellent customer service.

We value building long-lasting partnerships with our clients, and we are committed to ensuring your satisfaction. When you choose us as your supplier of Aluminum Profiles in Panama, you can trust that you are working with a reliable and trustworthy partner.

Contact us today to discuss your Aluminum Profiles needs and let us contribute to the success of your projects. We look forward to serving you and providing you with the best solutions in Panama.

Our team of professionals is dedicated to providing you with seamless procurement services, from sales and quotations to technical support. We understand the unique requirements and challenges of the Panama market, and we are well-prepared to offer valuable insights and assistance throughout the process.

With our strong partnership with CNBM, a Fortune Global 500 company, we have access to a wide range of high-quality products and resources. This enables us to provide you with competitive prices, timely delivery, and excellent customer service.

We value building long-lasting partnerships with our clients, and we are committed to ensuring your satisfaction. When you choose us as your supplier of Aluminum Profiles in Panama, you can trust that you are working with a reliable and trustworthy partner.

Contact us today to discuss your Aluminum Profiles needs and let us contribute to the success of your projects. We look forward to serving you and providing you with the best solutions in Panama.