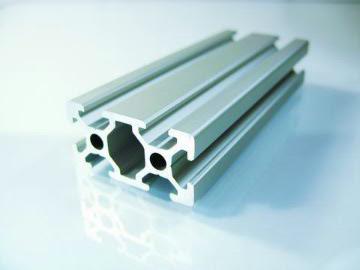

Industrial Aluminum Profile for LED Tape Light Strip

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Industial Aluminum Profile

Alloy: 6063, Temper: T5, T6.

surface:mill finished,anodized3.

widely used for building,furniture,transportation

Industial Aluminum Profile

Alloy: 6063,

Temper: T5, T6.

building,furniture,transportation,machine

Anodized silver, anodized champagne, anodized bronze, anodized black, powder coated, electrophoresis, polished, Thermal break, wooden grain.

Length: 5.8---6 meters, depend on customers' requested.

Packing: kraft paper, carton, or on customers' requested.

Exported to different countries worldwide.

- Q: This question asks if aluminum profiles can be utilized in cold weather conditions and seeks an explanation for their suitability.

- <p>Yes, aluminum profiles can be used in cold climates. Aluminum is a lightweight and durable material that maintains its strength and structural integrity even in extreme low temperatures. It does not rust or corrode, which makes it ideal for use in environments with harsh weather conditions. Additionally, aluminum has good thermal conductivity, which allows it to dissipate heat effectively, but it also has low thermal expansion, meaning it does not expand or contract significantly with temperature changes. This characteristic helps prevent warping or cracking in cold climates. Properly designed and installed aluminum profiles can withstand the challenges of cold weather without compromising their performance or longevity.</p>

- Q: Can aluminum profiles be used for modular exhibition booths?

- Indeed, modular exhibition booths can utilize aluminum profiles. Being light in weight, durable, and simple to assemble, aluminum profiles prove to be an excellent selection for crafting such booths. Customization and reconfiguration of these profiles to meet specific design needs is effortless. Moreover, these profiles provide a polished and professional look and can be employed in constructing walls, frames, panels, and display shelves within the booth. Furthermore, aluminum profiles are easily transportable and storable, rendering them a pragmatic choice for exhibition booths that require frequent setup and dismantling.

- Q: Can aluminum profiles be used for electrical busbars?

- Yes, aluminum profiles can be used for electrical busbars. Aluminum offers excellent electrical conductivity, and its lightweight nature makes it a cost-effective choice for busbar applications. Additionally, aluminum profiles can be easily shaped and customized to meet specific requirements, making them suitable for various electrical systems.

- Q: Are aluminum profiles suitable for use in chemical processing environments?

- Yes, aluminum profiles are generally suitable for use in chemical processing environments. Aluminum has excellent corrosion resistance properties and can withstand various chemicals, acids, and bases. Additionally, aluminum profiles can be further enhanced with protective coatings or anodization to provide even greater resistance to chemical exposure. However, the suitability may depend on the specific chemicals and conditions involved, so it is important to consult with experts or suppliers to ensure the best choice of aluminum profiles for a particular chemical processing environment.

- Q: What kinds of profiles are made of aluminium alloy windows?

- Four, look at the materialMaterial in the material, there are 6 main areas of reference:The thickness: Aluminum Alloy sliding window of 70 series, 90 series two, Aluminum Alloy housing interior sliding doors with 70 series. The number of aluminum alloys indicates the number of millimeters of the thickness of the door frame. Common aluminum alloy sliding window has 55 series, 60 series, 70 series, 90 series of four kinds. Selection should be based on the window size and the local wind pressure value is determined as shall be not less than 70 series Aluminum Alloy closed balcony sliding window.The strength: tensile strength should be 157 per square millimeter of Newton, yield strength to reach 108 per square millimeter of Newton. When buying, you can moderate bending profiles, and then you should be able to restore the original state.3: the same color Aluminum Alloy profile color should be consistent, such as color, that is not to buy.The flatness: check the Aluminum Alloy profile surface, should not sag or bulge.The gloss: avoid buying Aluminum Alloy doors and windows opening on the surface of the bubble (white) and ash (black), crack, burr, profile leather and other obvious defects.The oxidation degree of oxide film thickness should reach 10 micron. When choosing, light the surface of the profile to see if the oxide film on the surface can be removed.

- Q: What is the difference between aluminum alloy and 6063-T5 6060-T66?

- 6060-T66, higher strength, average mechanical performance is higher than T6 under 20-30Mpa condition [T66 is in T6 (solid solution strengthening + fully artificial aging) condition, strengthened by special process status - in European standard can be found] 6063-T5 is the most common aluminum alloy and delivery condition, and most of the architectural profiles are applied

- Q: Can aluminum profiles be used for exhibition stands?

- Yes, aluminum profiles can be used for exhibition stands. Aluminum is a popular choice for constructing exhibition stands due to its lightweight nature, durability, and versatility. It allows for easy transportation and assembly, while providing a sleek and professional appearance. Additionally, aluminum profiles can be customized to fit specific design requirements, making them ideal for creating unique and eye-catching exhibition displays.

- Q: This question asks about the various materials used to coat aluminum profiles for improving their appearance.

- <p>There are several types of coating materials used on aluminum profiles for aesthetic purposes, including: 1. Powder coating, which offers a durable and colorful finish. 2. Anodizing, a process that enhances the surface hardness and provides a decorative effect. 3. Electrophoretic coating, known for its smooth and even finish. 4. PVDF (Polyvinylidene Fluoride) coating, which is weather-resistant and offers a wide color palette. 5. Thermal spraying, which can provide a decorative or protective layer. 6. Sol-gel coating, a newer technology that offers excellent adhesion and corrosion resistance. These coatings not only enhance the visual appeal but also protect the aluminum from environmental factors and wear.</p>

- Q: Is aluminum alloy made of industrial aluminum?

- Three, according to the requirement of surface treatment: 1. anodic alumina material 2. electrophoretic coating aluminum powder spraying 3. aluminum 4. aluminum 5. aluminum transfer grain planing (divided into mechanical polishing and chemical polishing of two, the chemical polishing of the highest cost, the price is the most expensive)

- Q: What are the weatherproofing properties of aluminum profiles?

- Aluminum profiles have excellent weatherproofing properties due to their inherent resistance to corrosion and their ability to withstand extreme weather conditions. They are highly durable and can effectively protect against moisture, UV radiation, and temperature fluctuations, making them ideal for outdoor applications. Additionally, aluminum profiles can be treated with various coatings or finishes to enhance their weather resistance even further.

Send your message to us

Industrial Aluminum Profile for LED Tape Light Strip

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords