Aluminum Alloy Door and Window Profiles for Power Amplifier Aluminum Heat Sink Aluminum Profile

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Heat Sink Aluminum Profile for Power Amplifier

Alloy | State | Tensile Strength δbMpa | Non-proportional Stretching Stress(δp0.2Mpa) | Stretching rate (δ%) | Pattern Thickness (mm) | HV | HW |

No Less Than | |||||||

6061 | T4/T6 | 180/265 | 110/245 | 16/8 | - | - | - |

6063 | T5/T6 | 160/205 | 110/180 | 8/8 | 0.8/- | 58/- | 8/- |

6063A | T5/T6 | 200,190/230,220 | 160,150/190,180 | 5,5/5,4 | 0.8,0.8/-,- | 65,65/-,- | 10,10/-,- |

2. Application of Aluminum Heat Sink Aluminum Profile for Power Amplifier

wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors,windows…

3. Feature of Aluminum Heat Sink Aluminum Profile for Power Amplifier

Surface Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Decoration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mochenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

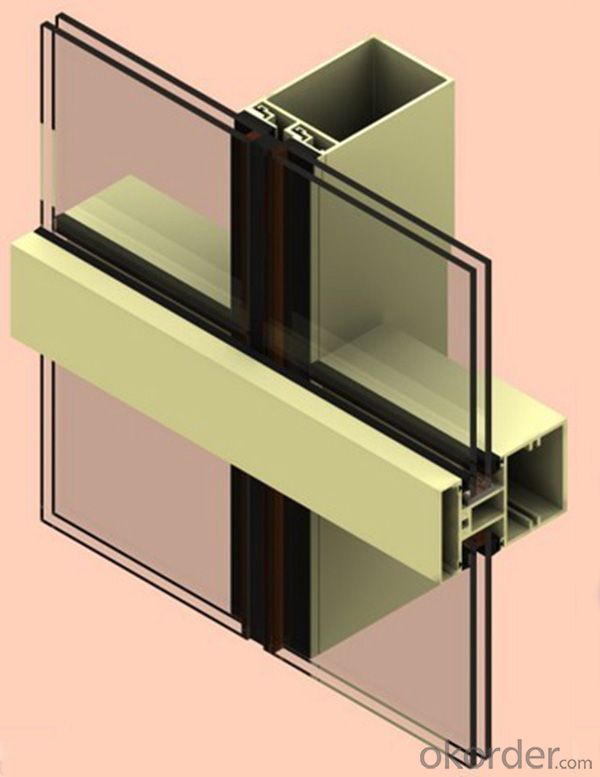

5. Image of Aluminum Heat Sink Aluminum Profile for Power Amplifier

6. Package and shipping of Aluminum Heat Sink Aluminum Profile for Power Amplifier

First, plastic cloth with drying agent inside; Second, Pearl Wool; Third, wooden cases with dry agent, fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

Question 1: What is your MOQ?

We accept one ton per type for an order. But the detail we could negotiate.

Question 2: What is your normal terms of payment?

We always trade with you by T/T. But we also accept the L/C as you require.

Question 3: How many kinds of the surface treatment we can choose?

You could choose different color of powder coated. Anodized of black. matte silver, nature, champagne, bronze color. Mill finished. Wooden finished and printed.etc.

Question 4: Can you supply OEM services?

We offer OEM services for 17 years.

Question 5: How many days for opening the mould?

Normally about 10 days.According to the difficulty of your drawing.

Question 6: Can i choose the package what i want?

Yes, of course. We offer various kinds of package.e.g.PE foam. Shrink film. Wrapping paper.

But we would give you professional suggestion of package.

- Q: This question seeks to understand the various types of aluminum profiles that are specifically utilized in the construction of railings and fences.

- <p>Aluminum profiles for railings and fences come in various types, each designed for specific applications and aesthetic preferences. Common types include: 1) Rectangular profiles, which are versatile for both commercial and residential settings; 2) Square profiles, offering a modern look and are often used in minimalist designs; 3) Round profiles, providing a classic appearance suitable for traditional or vintage styles; 4) Slotted profiles, which allow for easy assembly and are popular for their adjustability; 5) Hollow profiles, known for their strength and lightness, ideal for high-load applications; 6) Angled profiles, used to create corners and intersections in railing and fence designs. Each type can be further customized in terms of size, thickness, and finish to meet specific project requirements.</p>

- Q: Who would like to know, aluminum radiator mainly used in which instruments or equipment, trouble to say more detailed points, thank you

- Application of aluminum radiator is quite extensive, you do not know where to, because he has the quality of light, and the price is reasonable, the general electronic instruments and equipment will be used, such as TV, audio amplifier, car circuit board, CPU computer graphics.

- Q: How much is aluminum freight per kilometer per ton?

- The most accurate and effective way of Logistics: find a phone call to ask ah, less than 1 tons and tons of vehicle and hair are not the same, where to go is not the same, some small place to transfer is much more expensive, General Logistics 1 tons in about 500

- Q: Is it possible to utilize aluminum profiles for constructing exterior railings and staircases?

- <p>Yes, aluminum profiles can be used for exterior railings and staircases. They are known for their durability, resistance to corrosion, and low maintenance requirements, making them ideal for outdoor applications. Aluminum's strength and lightweight properties also contribute to its suitability for these structures. However, it's important to ensure that the aluminum is of high quality and properly treated to withstand weather conditions and ensure longevity.</p>

- Q: How do aluminum profiles contribute to daylighting strategies?

- Daylighting strategies rely on aluminum profiles to effectively utilize natural light in buildings. These profiles are utilized in the construction of windows, skylights, and curtain wall systems, promoting the optimal penetration of sunlight into interior spaces. A key benefit of incorporating aluminum profiles into daylighting strategies lies in their capacity to support sizable glass panes. Aluminum possesses a lightweight yet robust structure, facilitating the creation of expansive glazing systems that maximize the transmission of natural light. These profiles can be designed with slim sightlines, enabling unobstructed views and greater ingress of sunlight. In addition, aluminum profiles can be thermally insulated, featuring a layer of insulation between their interior and exterior sections. This thermal break effectively prevents the transfer of heat and cold, thereby enhancing the energy efficiency of the building. By minimizing thermal bridging, aluminum profiles minimize heat or cool air loss, resulting in reduced energy consumption for heating and cooling systems. Furthermore, aluminum profiles can be coated with a variety of finishes to enhance their daylighting performance. For example, reflective coatings redirect sunlight deeper into the interior, augmenting overall brightness within the space. Such coatings also serve to reduce glare and regulate sunlight intensity, creating a more comfortable and visually appealing environment. Moreover, aluminum profiles offer design flexibility and customization options. They can be molded into diverse shapes and sizes, empowering architects to devise innovative and distinctive daylighting solutions. Whether curved, angled, or combined with other materials, these profiles enable the realization of specific aesthetic and functional requirements. In summary, aluminum profiles significantly contribute to daylighting strategies by promoting the efficient utilization of natural light in buildings. Through their structural strength, thermal capabilities, and customizable nature, these profiles enable the creation of expansive glazing systems that optimize sunlight entry while maintaining energy efficiency and visual comfort.

- Q: This question asks if aluminum profiles can be utilized for constructing interior partitions or walls within a building.

- <p>Yes, aluminum profiles can be used for interior partitions or walls. They are lightweight, durable, and offer excellent resistance to corrosion. Aluminum profiles are easy to install and can be used in various configurations, making them suitable for both residential and commercial spaces. They also provide good thermal insulation and can be combined with other materials like glass or fabric for aesthetic and functional purposes.</p>

- Q: What are the regulations and standards that govern the use of aluminum profiles in construction?

- <p>Yes, there are several regulations and standards related to the use of aluminum profiles in construction. These include international standards such as ISO 7039 for anodized aluminum and ISO 9001 for quality management systems. Additionally, regional standards like the European EN 755 for extruded aluminum alloys and the American Architectural Manufacturers Association (AAMA) standards for aluminum products in buildings are crucial. Compliance with these standards ensures the safety, durability, and performance of aluminum profiles in construction applications.</p>

- Q: How is the thickness of the base plate of the aluminum profile radiator calculated? Are there formulas for calculation?

- There should be empirical formula, the heat of the surface heat dissipation is related to thermal conductivity, thickness, temperature change, surface area. Then the best thickness is calculated by linear programming.

- Q: What are the different types of anodizing options for aluminum profiles?

- There are several types of anodizing options for aluminum profiles, including sulfuric acid anodizing (SAA), chromic acid anodizing (CAA), hard anodizing, and two-step anodizing. SAA is the most common type, providing a durable and corrosion-resistant finish. CAA offers a thinner and less durable coating, but it is commonly used for aerospace applications. Hard anodizing produces a thicker and harder coating, ideal for high-wear applications. Two-step anodizing involves an additional coloring process, allowing for a wide range of decorative finishes.

- Q: How about the price of aluminum profile?

- Aluminum prices are calculated according to the price of aluminum ingot + processing fees, such as: aluminum ingot price 16000+, processing fee 6000 = 22000 yuan / ton

Send your message to us

Aluminum Alloy Door and Window Profiles for Power Amplifier Aluminum Heat Sink Aluminum Profile

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords