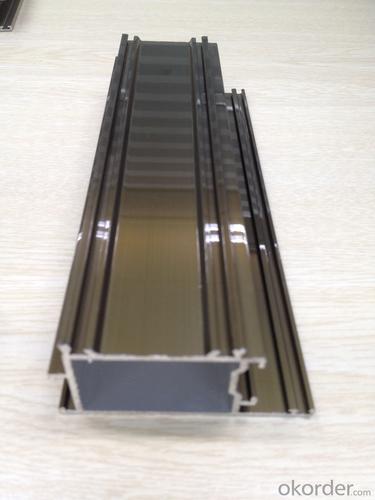

Aluminum Pipes for Building Material Aluminum Profile

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are the largest aluminum profilemanufacture in

Material | Alloy Aluminum 6063,6061,6005,6082 or customer nominated |

Temper | T3, T4, T5, T6 and other |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Not more than 16 meters |

Good Package | Inner plastic film /outside carton/wooden pallets |

Payment Method | T/T, L/C, etc |

Delivery Time | Normally 2-4 weeks, Delivery time can be consulted. |

Press Machine | 500-12500 tons all together 93 press lines. |

Fabrication | 1. Furniture;2. Drilling; 3. Bending; 4. Cutting; 5. Windows and doors;6.etc. |

Certificate | ISO/TS 16949,DNV,IRIS,CCS,AFA,etc. |

Dies | 1. Using our dies, no fee; |

2. Using customer drawing, opening dies, usually about 5~50 tons then the dies cost can be refunded. | |

3. Die cost is negotiable base on the order quantity | |

Capability | Annual output 800,000 tons |

- Q: How to distinguish between copper tube or aluminum pipe?

- I am back to a repair is already installed. I worried about this version is not the original version, tangled ah, he said can Quanguolianbao 3 months but you have to take what I call if I give evidence of bad warranty can be taken directly that you can trustChasing the answerIs it mainly made of copper tubes into aluminum tubes now?. If it is, you can ask for replacement, the aluminum pipe is not innate than copper tube, especially for a long time, the aluminum tube is easy to punch.

- Q: 1100 what is the difference between the aluminum tube and the 6063 material aluminum tube, please advise

- The 1100 is rust proof aluminum grades, good corrosion resistance, good plasticity, but the intensity is the lowest, 6063 forging Aluminum Alloy, is Aluminum Alloy, if after solid solution treatment and aging, high strength and hardness, but the corrosion resistance of less than 1100,

- Q: Are aluminum pipes lightweight?

- Yes, aluminum pipes are lightweight.

- Q: Aluminum seamless aluminium oxidation welding line how to do?

- If you decide to buy is seamless aluminium oxide, it is certainly not possible after the welding line, if there is a welding line, that is the hot extrusion of aluminum, aluminum is seamed we usually say, if it is oxidized welding line, there is no way to solve, can't use it can only be scrapped in fact, the hot extruded aluminum tube also can avoid the welding line, this time you have to order and that of the factory, this can be solved above the mold! At least your eye is very ugly after oxidation of a welding line. In fact, seamed pipe and seamless pipe mainly is the surface quality, but the mechanical properties!

- Q: What is the difference between aluminium pipe and aluminium alloy pipe?

- Aluminum tube refers to a pure aluminum or aluminum alloy by extrusion processing into its longitudinal length of hollow metal tubular material. There may be one or more closed through holes with uniform wall thickness and cross section to be delivered in a straight or coiled form. Widely used in automobiles, ships, aerospace, aviation, electrical appliances, agriculture, machinery and electrical, home and other industries.

- Q: Can aluminum pipes be used for hydroponic systems?

- Yes, aluminum pipes can be used for hydroponic systems. Aluminum pipes are lightweight, durable, and resistant to corrosion, making them an ideal choice for hydroponic applications. They can be easily cut and assembled to create a customized hydroponic system that meets the specific needs of plants. Aluminum pipes also have good thermal conductivity, allowing for efficient heat transfer in the system. However, it is important to note that aluminum pipes should be properly coated or lined to prevent any potential leaching of aluminum into the nutrient solution, which can be harmful to plants.

- Q: The aluminum pipe in the fridge is leaking. What should I do to fill it up?

- With good brothers gluing, 1; polished by voile. 2; with good brothers glued on the line, remember a few times glue.

- Q: Do aluminum pipes expand or contract with temperature changes?

- Aluminum pipes expand with temperature increases and contract with temperature decreases.

- Q: Are aluminum pipes suitable for chemical storage facilities?

- Due to their potential reactivity with certain chemicals, aluminum pipes might not be the optimal choice for chemical storage facilities. Although aluminum is typically resistant to corrosion, it can still undergo reactions with certain acids and alkaline substances, resulting in damage and potentially jeopardizing the pipes' integrity. Moreover, aluminum pipes may lack the essential strength and durability necessary for the safe handling and storage of chemicals. To identify the most suitable pipes for specific chemical storage requirements, it is recommended to seek advice from a chemical engineer or a material compatibility expert.

- Q: resulting in the pipe can not be used after folding, how to deal with? Fifteen08 years to buy three AUX air-conditioning, moving this year, the pipe was folded, and then installed, AUX said after the sale of the pipe can not be used, to replace all new, because the aluminum pipe can not be welded. We all know that the tube is very expensive, then bought 5 meters or so, I think it will not have to spend money again, I did not expect, because of this reason, even for old pipes, the installation of new tubes, but also spend nearly 1000 yuan. When I bought it, I didn't think they would use the aluminum tube. I thought it was copper. It was entirely cost saving by the factory, which made the consumer pay the bill. I was so angry that I didn't buy anything from AUX any more. Would you like to ask if you have ever touched this situation? What can you do to reuse the old pipes?

- You only have to spend this money, or who help you install.

Send your message to us

Aluminum Pipes for Building Material Aluminum Profile

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords