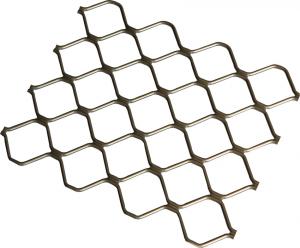

Aluminum Grills Mesh Moulding Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

aluminum mesh

1)Material : 6063 6061 6060 and different aluminium alloy

2)Status:T4 T5 T6 or other special status

3)Surface treatment: mill finish, anodized sliver ,anodized bronze, anodized champagne, anodized black pearl, various power coating color, electrostatic sliver, electrostatic champagne, electrostatic golden, electrostatic titanium , machine polish sliver, machine polish bronze, wooden grain color, and Fluorocarbon spraying.

4)Annual capacity : 120000TON

5)Quality : China Nation Standard GB/T 5237 2008 (advanced class)

6)Use: can be widely using aluminium window, door, curtain wall, hand railing , normal aluminium profile, decorative and industrial aluminium profile

7)Advantage: Famous Brand reasonable&market price, soonest delivery and good after sale- service

8)Type of package:protection foam+heat contracted plastic film. / wooden packing / Metal pallet or depand on clientspecial requirement.

9)Payment term:T/T:30% of total value as deposite should paid by T/T within 3 days when confirmation ,and the remaining sum should be paid by T/T before delivery.L/C: 100% at sight

10)Delivery Day: 15-30days

11)Honor : CHINA FAMOUS TRADEMARK, CHINA TOP BRAND, ISO9001-2000, CHINA SQUARE&ROUND COMMITTEE DNV

- Q: What is wearing a heat insulation aluminum profile? What is pouring heat insulation aluminum profile?

- Process a comparison, "wear type" VS "pouring" process comparison (1) production process strip insulation aluminum strip, generally separated teeth, rolling three steps, there are equipment manufacturers opened the teeth and wear on a piece of equipment to complete, known as the "two step". Gulleting: is a hard roll with gear device will aluminum part out of insulation to tooth wear. The aim is to increase the roughness of the profile by hobbing, thereby increasing the shear force of the composite profile. As the profile is divided into two parts, both inside and outside, according to the needs of production, gear equipment is generally two units. Wear: it is to wear the insulation strip to the profile, the inside and outside the two parts linked together, for the next step rolling preparation. Just one device. Rolling: the process can be divided into three steps: direction and pre clamping, main clamping and straightening (horizontal direction and vertical direction). It is the key to ensure the compactness and verticality of finished profiles. (2) the production process of "casting" is the surface treatment of aluminium and good linear motion through the driving system, the heat insulation slot of the aluminum profile after bottom pouring head pouring machine, liquid flow to the heat insulation material groove, after solidification after a period of time and then cut the bridge.

- Q: This question asks for an explanation of the various methods employed in the manufacturing of aluminum profiles.

- <p>Aluminum profiles are produced using several manufacturing processes, each suited to different applications and profile shapes. The primary methods include: Casting, where molten aluminum is poured into molds to form profiles; Extrusion, the most common process, where aluminum is pushed through a die to create long, continuous shapes; Rolling, used for creating flat or curved sheets and plates; Forging, which involves shaping aluminum by applying compressive forces; and Machining, where aluminum profiles are cut and shaped using tools. Each process has its advantages and is chosen based on the desired profile's complexity, strength, and cost-effectiveness.</p>

- Q: What are the different surface polishing options for aluminum profiles?

- Aluminum profiles offer various surface polishing options, each with its own shine and finish levels. These methods include mechanical polishing, chemical polishing, electrolytic polishing, and anodizing. Mechanical polishing involves using abrasives and polishing compounds to physically eliminate surface imperfections and achieve a smooth, reflective finish. This can be done manually or with automated machines. While it provides a high shine, it requires careful attention to detail and multiple steps. Chemical polishing, on the other hand, employs chemical solutions to dissolve a thin layer of aluminum, resulting in a smoother surface. It is often used for large-scale production due to its quick and uniform application, but it may not offer the same level of shine as mechanical polishing. Electrolytic polishing utilizes an electric current to eliminate surface imperfections and create a polished finish. By using the aluminum profile as an anode and a conductive material as the cathode, electrolytic polishing produces a mirror-like finish with excellent precision and uniformity. Although not a polishing method itself, anodizing is a commonly used surface treatment for aluminum profiles. It involves creating a protective oxide layer on the metal's surface through an electrochemical process. Anodizing enhances the appearance of profiles by providing a smooth, colored, or clear finish, while also improving their durability and resistance to corrosion. The choice of surface polishing option depends on factors such as the desired shine level, the complexity of the profile's design, and the intended application. It is essential to consider cost, time, and quality requirements when selecting the most suitable option, as each method has its advantages and limitations.

- Q: How can I distinguish aluminum from aluminium oxide or electrophoresis aluminum or spray aluminium material?

- The electrophoretic material looks very textured, very uniform, and full range. Spray paint will not spray in some places, and the color is not as good as electrophoresis.

- Q: This question asks for the standard specifications and measurements of aluminum profiles that are frequently utilized in construction projects.

- <p>Aluminum profiles used in construction come in various specifications and measurements. Commonly, they are categorized by series such as 6060, 6061, 6063, and 6082, each with different mechanical properties. Sizes can range from small profiles like 20x20mm to large ones like 200x200mm or more. Thicknesses typically vary from 1mm to 6mm, depending on the structural requirements. Lengths can be customized but are generally available in standard lengths such as 6 meters. The profiles are measured in terms of their width, height, and thickness, and they are designed to meet specific load-bearing and aesthetic needs in construction. It's important to consult with suppliers or construction specifications for the exact measurements required for a particular project.</p>

- Q: What are the different bending radii available for aluminum profiles?

- Depending on the specific application requirements, the available bending radii for aluminum profiles can vary. However, aluminum profiles typically offer a range of bending radii options to accommodate different needs. Common bending radii for aluminum profiles include 1.5D, 2D, 3D, and 4D. In these radii, the "D" refers to the outer diameter of the profile. For instance, a 1.5D bending radius indicates that the bend radius is 1.5 times the outer diameter of the profile. The choice of bending radius depends on various factors, such as the thickness and alloy of the aluminum, the desired bending angle, and the intended application. Smaller bending radii are often employed for tighter bends or when a more compact design is necessary. Conversely, larger bending radii are suitable for gentler bends or when maintaining the structural integrity of the profile is crucial. It is important to note that the bending process can impact the mechanical properties of the aluminum profile, including its strength and stiffness. Therefore, it is crucial to carefully consider the bending radius to ensure that the profile retains its desired properties post-bending. To determine the most appropriate bending radius for a specific aluminum profile, it is advisable to seek guidance from manufacturers or experts knowledgeable in aluminum bending processes. They can offer valuable insights based on the specific requirements and limitations of the application.

- Q: What are the load-bearing capacities of different aluminum profile shapes?

- The load-bearing capacities of different aluminum profile shapes vary depending on various factors such as the specific alloy of aluminum used, the size and dimensions of the profile, and the specific application or use case. Aluminum profiles, also known as extrusions, come in a wide range of shapes including I-beams, T-beams, square tubes, rectangular tubes, angles, and channels. Each profile shape has its own unique load-bearing capacity due to its structural design and cross-sectional properties. For example, I-beams are known for their high load-bearing capacity due to their shape, which allows for efficient weight distribution along the flanges. They are commonly used in structural applications where heavy loads need to be supported. T-beams, on the other hand, have a load-bearing capacity similar to I-beams but with a different cross-sectional shape. They are often used in applications where a flat surface is required on one side, such as in construction or automotive industries. Square and rectangular tubes are versatile profiles that are often used in building structures, frames, and support systems. Their load-bearing capacity depends on the wall thickness and size of the tube. Angles and channels, which have a L-shaped and U-shaped cross-section respectively, are commonly used in construction and manufacturing industries. Their load-bearing capacity depends on the size and dimensions of the profile. It is important to note that the load-bearing capacities of aluminum profiles are typically provided by the manufacturer and should be consulted for specific applications. Additionally, engineering calculations and considerations such as deflection, bending moments, and safety factors should be taken into account when determining the appropriate aluminum profile shape and size for a given load-bearing requirement.

- Q: How do aluminum profiles perform in terms of creep resistance?

- Aluminum profiles generally have good creep resistance due to their high strength and stiffness. They can withstand sustained loads and high temperatures over a long period of time without significant deformation. However, the creep resistance of aluminum profiles may vary depending on the specific alloy and manufacturing process used.

- Q: Are aluminum profiles resistant to termites and insects?

- Yes, aluminum profiles are highly resistant to termites and insects. Unlike wood, which is susceptible to termite infestations and insect damage, aluminum is a nonporous material that does not provide a food source for these pests. Additionally, aluminum profiles are typically coated with protective finishes, such as powder coating or anodizing, which further enhance their resistance to termites and insects. This makes aluminum profiles a durable and long-lasting option for various applications, such as window frames, door frames, and other construction projects where termite or insect damage is a concern.

Send your message to us

Aluminum Grills Mesh Moulding Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords