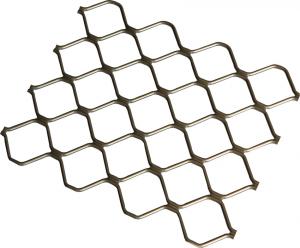

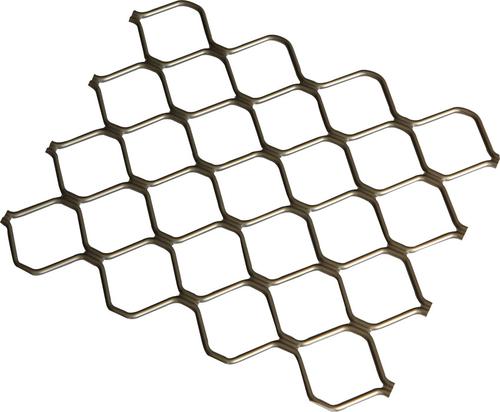

China Aluminum Frame Extrusion Profiles for Aluminum Mesh

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ALUMINUM MESH

Industrial aluminium profile

1)Material : 6063 6061 6060 and different aluminium alloy

2)Status:T4 T5 T6 or other special status

3)Surface treatment: mill finish, anodized sliver ,anodized bronze, anodized champagne, anodized black pearl, various power coating color, electrostatic sliver, electrostatic champagne, electrostatic golden, electrostatic titanium , machine polish sliver, machine polish bronze, wooden grain color, and Fluorocarbon spraying.

4)Annual capacity : 120000TON

5)Quality : China Nation Standard GB/T 5237 2008 (advanced class)

6)Use: can be widely using aluminium window, door, curtain wall, hand railing , normal aluminium profile, decorative and industrial aluminium profile

7)Advantage: Famous Brand reasonable&market price, soonest delivery and good after sale- service

8)Type of package:protection foam+heat contracted plastic film. / wooden packing / Metal pallet or depand on clientspecial requirement.

9)Payment term:T/T:30% of total value as deposite should paid by T/T within 3 days when confirmation ,and the remaining sum should be paid by T/T before delivery.L/C: 100% at sight

10)Delivery Day: 15-30days

11)Honor : CHINA FAMOUS TRADEMARK, CHINA TOP BRAND, ISO9001-2000, CHINA SQUARE&ROUND COMMITTEE DNV

- Q: Can aluminum profiles be used in the production of agricultural equipment?

- Aluminum profiles have the potential to be utilized in the manufacturing of agricultural equipment. The versatility and lightweight characteristics of aluminum provide numerous benefits for agricultural applications. Its resistance to corrosion is crucial when considering equipment that is exposed to outdoor conditions and various farming chemicals. Moreover, aluminum profiles have the capability to be easily molded and customized to meet specific design requirements, enabling the creation of intricate and functional agricultural equipment. The lightweight nature of aluminum also simplifies the transportation and handling of the equipment, resulting in reduced labor costs. Additionally, aluminum profiles are recyclable, making them an environmentally conscious choice for the production of agricultural equipment. In conclusion, incorporating aluminum profiles into agricultural equipment can enhance durability, efficiency, and sustainability within the farming industry.

- Q: This question asks about the variety of dimensions and forms that aluminum profiles can come in.

- <p>Aluminum profiles are available in a wide range of sizes and shapes to suit various applications. Common shapes include rectangular, square, circular, and special profiles like angles, channels, and tees. Sizes can vary from thin strips to thick bars, with specific dimensions tailored to the needs of the project. The profiles can be flat, hollow, or have complex cross-sectional geometries. They are also available in different surface finishes, such as anodized, painted, or powder-coated, to enhance their appearance and durability. The selection of aluminum profiles depends on the structural requirements, design specifications, and the industry they are intended for, such as construction, automotive, or aerospace.</p>

- Q: This question asks for a variety of green building materials that incorporate recycled aluminum profiles, indicating an interest in sustainable construction practices.

- <p>Recycled aluminum profiles are used in various green building materials to promote sustainability. These include: 1) Window and door frames, known for their durability and energy efficiency. 2) Facade systems, which provide a lightweight and strong alternative to traditional materials. 3) Structural components, such as beams and columns, offering strength with less material. 4) Roofing materials, which can be lightweight and resistant to corrosion. 5) Modular building systems, which use prefabricated aluminum components for quick assembly. 6) Fencing and railings, offering a low-maintenance option. 7) Solar panel supports, combining recycled aluminum with renewable energy technology. These materials reduce waste, save energy, and lower carbon emissions in construction.</p>

- Q: High compartment aluminum profiles are generally divided into several specifications, what are the attributes?

- Aluminum alloy profiles are basically no GB non-standard, but the state has special specifications for architectural aluminum profiles, mainly on the thickness of the material, materials and so on.Each aluminum alloy profiles manufacturing enterprises are basically similar products, but in specific structure of the discrepancy. But such as the more general series, such as GB 50, 868, and 90, these are basically the same.The 80 series and the 60 series refer to the aluminium alloy profiles with widths of 80 mm and 60 mm.

- Q: How are aluminum profiles joined together?

- Depending on the desired strength, functionality, and aesthetic appeal, various methods can be employed to join aluminum profiles. The most commonly utilized techniques include mechanical fastening, welding, and adhesive bonding. When it comes to ease of assembly and disassembly, mechanical fastening is a preferred option. Screws, bolts, nuts, rivets, and self-tapping screws are frequently employed to connect aluminum profiles, ensuring a stable and secure joint that allows for easy adjustment or dismantling. Welding, on the other hand, presents an effective means of joining aluminum profiles. Techniques such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) can be applied to melt and fuse the profiles together, resulting in a strong and permanent joint. Welding finds common usage in structural applications where high strength and rigidity are imperative. For a more visually appealing connection, adhesive bonding is often employed. Industrial-grade adhesives specifically formulated for aluminum bonding create a robust bond between the profiles. This method offers a seamless appearance, with no visible fasteners or weld marks. Adhesive bonding is commonly utilized in architectural applications, where a clean and sleek finish is desired. In certain instances, a combination of these methods may be employed to achieve the desired joint. For example, adhesive bonding can secure the profiles together, while mechanical fasteners provide additional strength and stability. Ultimately, the choice of joining method is contingent upon factors such as the application, required strength, accessibility, and desired appearance. Manufacturers and fabricators meticulously consider these factors to determine the most suitable method for joining aluminum profiles.

- Q: Can aluminum profiles be used in exhibition booth and stand manufacturing?

- Yes, aluminum profiles can be used in exhibition booth and stand manufacturing. Aluminum profiles offer several advantages in this context. Firstly, they are lightweight, making them easy to transport and assemble at the exhibition venue. This also helps in reducing shipping costs. Secondly, aluminum profiles are highly durable and can withstand heavy usage. They are resistant to corrosion, ensuring that the exhibition booth or stand remains in good condition even after multiple uses. Additionally, aluminum profiles allow for easy customization and flexibility in design. They can be easily cut, shaped, and joined together to create various structures and configurations for the exhibition booth or stand. Furthermore, aluminum profiles can be powder-coated or anodized to provide a professional and visually appealing finish. Overall, aluminum profiles are a popular choice in exhibition booth and stand manufacturing due to their lightweight, durable, and customizable nature.

- Q: What is a pouring type heat insulation aluminum profile?

- The liquid insulation material injection curing Aluminum Alloy section casting trough and temporary bridge resection Aluminum Alloy profiles of the casting trough to disconnect the connection through metal, insulation materials will be the two part Aluminum Alloy profile disconnect combined composite together.For more information, please visit the Dalian Chinese laborers' Creative Technology Limited website.

- Q: This question asks for the method to determine the amount of aluminum required for a construction project.

- <p>To calculate the weight of aluminum profiles needed for a building project, follow these steps: 1. Determine the length and cross-sectional area of each aluminum profile required. 2. Use the aluminum density, which is approximately 2.7 grams per cubic centimeter (g/cm鲁). 3. Multiply the volume (length 脳 cross-sectional area) by the density to get the weight of each profile. 4. Sum the weights of all profiles to get the total weight needed. Ensure to account for any additional material for joints, connections, and potential waste. It's also advisable to consult with an engineer or use specialized software for precise calculations tailored to your project's specific requirements.</p>

- Q: How do aluminum profiles contribute to the reduction of carbon footprint?

- Aluminum profiles contribute to the reduction of carbon footprint primarily through their lightweight nature and recyclability. As aluminum is a lightweight material, it requires less energy to transport and install compared to heavier materials, resulting in lower carbon emissions. Additionally, aluminum profiles are highly recyclable, allowing for the conservation of resources and reduction of energy consumption during the manufacturing process. By choosing aluminum profiles over other materials, carbon emissions can be minimized, contributing to a more sustainable and eco-friendly approach.

- Q: This question asks for methods to protect aluminum profiles from corrosion and damage during the processes of transportation and storage.

- <p>To prevent corrosion and damage to aluminum profiles during transportation and storage, follow these guidelines: 1. Keep aluminum profiles dry and clean. Moisture and dirt can accelerate corrosion. 2. Use protective packaging, such as plastic wrap or padded covers, to shield profiles from physical damage and moisture. 3. Store profiles in a cool, dry place away from direct sunlight and corrosive substances. 4. Stack profiles with appropriate padding between layers to prevent scratching. 5. Avoid overloading during transportation and ensure secure fastening to prevent movement and potential damage. 6. Regularly inspect stored profiles for signs of corrosion or damage and address any issues promptly.</p>

Send your message to us

China Aluminum Frame Extrusion Profiles for Aluminum Mesh

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords