Aluminum F Molding Extrusion Profiles - Well Structured and High Quality Aluminium Profiles

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminium Profile of Well Sturctured and Good Quality Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminium Profile of Well Sturctured and Good Quality:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

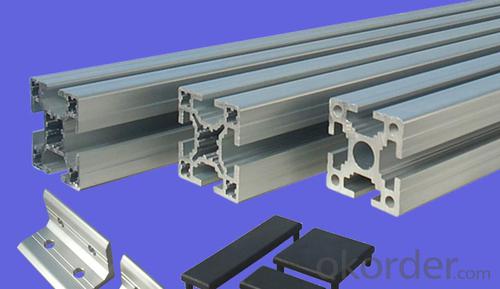

3.Aluminium Profile of Well Sturctured and Good Quality Images:

4.Aluminium Profile of Well Sturctured and Good Quality Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How do aluminum profiles perform in terms of heat resistance?

- Aluminum profiles possess commendable heat resistance properties, as they possess a relatively high melting point of 660.3°C (1220.5°F) and demonstrate a low coefficient of thermal expansion. These characteristics enable aluminum profiles to endure elevated temperatures without experiencing notable distortion or structural harm. Consequently, aluminum profiles are well-suited for diverse applications that demand heat resistance, including heat sinks, automotive components, and industrial equipment. Furthermore, aluminum's exceptional thermal conductivity facilitates effective dissipation of heat, further augmenting their performance in environments characterized by high levels of heat. Nevertheless, it is imperative to acknowledge that aluminum's heat resistance does not match the level of certain other metals like steel or titanium, thereby necessitating the consideration of alternative materials in exceedingly high-temperature scenarios.

- Q: What are the different surface engraving options for aluminum profiles?

- There are several surface engraving options available for aluminum profiles. Some of the most common methods include: 1. Laser engraving: This technique uses a high-powered laser to etch the desired design or text onto the surface of the aluminum profile. Laser engraving provides precise and clean results, making it ideal for intricate patterns and fine details. 2. Diamond drag engraving: Also known as diamond scratch engraving, this method uses a diamond-tipped tool to scratch the surface of the aluminum profile. It creates shallow grooves that can be used to create logos, serial numbers, or other simple designs. 3. Chemical etching: Chemical etching involves using a chemical solution to remove specific areas of the aluminum profile. This process is often used to create custom designs, patterns, or textures on the surface of the profile. 4. Mechanical engraving: Mechanical engraving utilizes a rotating cutting tool to engrave the aluminum profile. This method is commonly used for basic text or simple designs and can be done manually or with the help of a CNC machine. 5. Sandblasting: Sandblasting involves shooting a high-pressure stream of sand or other abrasive materials onto the surface of the aluminum profile. This process creates a textured surface and can be used to achieve a matte or frosted finish. Each of these surface engraving options offers unique benefits and can be chosen based on the desired outcome, complexity of the design, and budget considerations. It is important to consider factors such as durability, precision, and aesthetic appeal when selecting the most suitable engraving method for aluminum profiles.

- Q: How do aluminum profiles perform in seismic or earthquake-prone areas?

- Aluminum profiles have proven to be highly effective in seismic or earthquake-prone areas due to their unique properties. The lightweight nature of aluminum makes it a popular choice for construction in such areas as it reduces the overall weight of the structure, thus minimizing the potential for collapse during an earthquake. Additionally, aluminum possesses excellent ductility, meaning it can deform under stress without fracturing, which allows it to absorb and dissipate the energy generated by seismic activity. Moreover, aluminum profiles have high strength-to-weight ratio, allowing them to withstand the dynamic forces exerted during an earthquake. This strength, combined with the material's corrosion resistance, makes aluminum profiles particularly suitable for seismic areas where the risk of structural damage is heightened. Furthermore, aluminum is a highly malleable material, making it easy to shape and fabricate into various structural components. This flexibility allows for the creation of customized designs that can withstand seismic forces. Additionally, aluminum profiles can be easily bolted or welded together, providing a secure and reliable connection that further enhances the structural integrity of the building. It is important to note that the performance of aluminum profiles in seismic areas also depends on the overall design and construction techniques used. Proper engineering practices, such as incorporating seismic bracing systems or using specialized connectors, can further improve the performance of aluminum structures during earthquakes. Overall, due to its lightweight, ductile, strong, and corrosion-resistant properties, aluminum has proven to be a reliable and effective material for use in seismic or earthquake-prone areas. When appropriately designed and constructed, aluminum profiles can significantly enhance the safety and resilience of structures in these challenging environments.

- Q: This question asks about the variety of dimensions and forms that aluminum profiles can come in.

- <p>Aluminum profiles are available in a wide range of sizes and shapes to suit various applications. Common shapes include rectangular, square, circular, and special profiles like angles, channels, and tees. Sizes can vary from thin strips to thick bars, with specific dimensions tailored to the needs of the project. The profiles can be flat, hollow, or have complex cross-sectional geometries. They are also available in different surface finishes, such as anodized, painted, or powder-coated, to enhance their appearance and durability. The selection of aluminum profiles depends on the structural requirements, design specifications, and the industry they are intended for, such as construction, automotive, or aerospace.</p>

- Q: What are the advantages of utilizing aluminum profiles in construction projects in terms of environmental impact?

- <p>Aluminum profiles in construction offer several environmental benefits. They are highly recyclable, which reduces waste and conserves natural resources. Aluminum is lightweight, reducing transportation emissions. It also has a high strength-to-weight ratio, allowing for more efficient use of materials. Additionally, aluminum has excellent thermal conductivity, which can contribute to energy efficiency in buildings. Furthermore, aluminum production technology has advanced to reduce energy consumption and emissions during the manufacturing process. Overall, the use of aluminum profiles can lead to more sustainable and environmentally friendly construction practices.</p>

- Q: Can aluminum profiles be used in structural applications?

- Yes, aluminum profiles can be used in structural applications. Aluminum is a lightweight and durable material that offers excellent strength-to-weight ratio, making it suitable for various structural applications. Aluminum profiles are commonly used in the construction industry for the fabrication of frames, beams, columns, and trusses in buildings and infrastructure. These profiles are also used in the manufacturing of automotive components, aerospace structures, and marine applications. Aluminum profiles provide advantages such as corrosion resistance, ease of fabrication, and recyclability, making them a popular choice for structural applications.

- Q: What are the different types of fasteners used for aluminum profiles?

- Some of the different types of fasteners used for aluminum profiles include screws, bolts, nuts, rivets, and T-slot nuts. These fasteners are designed to securely join aluminum profiles together for various applications in industries such as construction, manufacturing, and automotive.

- Q: Are aluminum profiles capable of being tailored to fulfill unique design needs or standards?

- <p>Yes, aluminum profiles can be customized to meet specific design requirements or specifications. This customization can include varying the dimensions, finishes, and shapes to fit the intended application. Manufacturers can modify the extrusion process to create profiles with specific tolerances, surface treatments, and mechanical properties. This flexibility makes aluminum profiles suitable for a wide range of industries, including construction, automotive, and aerospace.</p>

- Q: This question asks about the characteristics of aluminum profiles, specifically whether they are lightweight and easy to handle.

- <p>Yes, aluminum profiles are known for their lightweight nature and ease of handling. They are made from aluminum, which is a lightweight metal with a low density. This makes aluminum profiles ideal for applications where weight is a concern, such as in construction, automotive, and aerospace industries. Additionally, their lightweight characteristic also contributes to their ease of handling, as they can be easily maneuvered and installed without requiring heavy machinery or excessive manpower.</p>

- Q: Is it feasible to recycle aluminum profiles and what factors affect the recycling process?

- <p>Yes, aluminum profiles can be recycled easily. Aluminum is one of the most recycled materials globally due to its low melting point, which requires less energy for recycling compared to other metals. The recycling process involves melting the aluminum, which can be done at temperatures significantly lower than those needed for other metals. Additionally, aluminum retains its properties even after multiple recycling cycles, making it an ideal material for sustainable use. The recycling rate of aluminum is high, and it contributes to energy savings and reduced environmental impact. However, the ease of recycling can be affected by factors such as the presence of impurities, the complexity of the profile shapes, and the efficiency of collection systems.</p>

Send your message to us

Aluminum F Molding Extrusion Profiles - Well Structured and High Quality Aluminium Profiles

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords