China Made Extruded Aluminum Profiles for Door Extrusion Profiles

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Extruded Profile Aluminium Profile To Make Doors Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Extruded Profile Aluminium Profile To Make Doors :

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

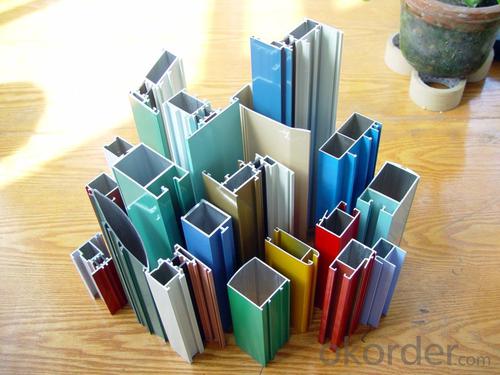

3.Extruded Profile Aluminium Profile To Make Doors Images:

4.Extruded Profile Aluminium Profile To Make DoorsSpecification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Are aluminum profiles resistant to pests or insects?

- Yes, aluminum profiles are generally resistant to pests or insects. Aluminum is a non-porous material that does not provide a suitable environment for pests or insects to nest or feed on. Unlike wood, which can be vulnerable to termite infestations, aluminum profiles are not susceptible to damage from insects. The smooth surface of aluminum makes it difficult for insects to crawl or burrow into, effectively preventing them from gaining access to the structure. Additionally, aluminum profiles are often used for windows, doors, and other entry points, and their tight seals further limit the entry of pests or insects into a building. Overall, aluminum profiles provide a durable and pest-resistant solution for various applications.

- Q: How do you install aluminum profiles?

- Follow these instructions for installing aluminum profiles: 1. Begin by measuring and cutting the profiles to the desired length using a saw equipped with a fine-tooth blade. It is essential to wear safety goggles and gloves during the cutting process. 2. Prior to installation, ensure the surface where the profiles will be placed is thoroughly cleaned. Remove any dirt, dust, or debris that could interfere with the installation. 3. Apply adhesive or silicone sealant to the back of the profile to securely attach it to the surface and create a watertight seal. 4. Position the profile on the surface and firmly press it down to guarantee proper adhesion. Utilize a level to ensure it is straight and correctly aligned. 5. If needed, utilize screws or fasteners to further secure the profile to the surface. Pre-drill pilot holes to prevent any cracking of the aluminum. 6. Repeat this process for each profile, leaving a small gap between them to account for expansion and contraction. 7. Once all profiles are installed, remove any excess adhesive or sealant. Use a damp cloth or sponge to wipe away any residue. 8. Allow the profiles to fully cure according to the manufacturer's instructions before applying any additional finishes or utilizing the area. Always consult the manufacturer's instructions for specific installation guidelines and recommendations.

- Q: What are the impact resistance properties of aluminum profiles?

- Aluminum profiles have excellent impact resistance properties due to their inherent strength and durability. They can withstand high impact forces without deforming or breaking, making them suitable for various applications where impact resistance is crucial, such as automotive, construction, and aerospace industries. Additionally, aluminum profiles can absorb and distribute impact energy effectively, minimizing the risk of damage or injury.

- Q: How about the weight calculation of 180 series semi concealed curtain wall aluminum profile

- There's something wrong with your questionFirst, do you mean the unit or the frame? (I think the unit may be a little bigger)Second, if it's the unit, your 180 is the two male boxes and the width is 180If you want to calculate the weight, no one will tell you, because the calculation requirements require your profile drawing

- Q: Aluminum bending or curling

- Ordinary people are squeezed out, take it with the mold, pull the bending and then aging, already aging good profiles can also pull the bend, that is, no aging before pulling good-looking, to pull the bend, the most important thing is to mold

- Q: What is the difference between aluminum alloy and 6063-T5 6060-T66?

- 6060-T66, higher strength, average mechanical performance is higher than T6 under 20-30Mpa condition [T66 is in T6 (solid solution strengthening + fully artificial aging) condition, strengthened by special process status - in European standard can be found] 6063-T5 is the most common aluminum alloy and delivery condition, and most of the architectural profiles are applied

- Q: Can aluminum be utilized as a material for constructing railings and fences?

- <p>Yes, aluminum profiles are commonly used for railings and fences due to their durability, low maintenance, and resistance to corrosion. They are lightweight, easy to install, and can be powder-coated in various colors to match architectural styles. Aluminum railings and fences are also appreciated for their strength and ability to withstand harsh weather conditions without rusting or rotting, making them a popular choice for both residential and commercial applications.</p>

- Q: I have a disinfection cabinet to cut off a piece of aluminum to install the control board, how to cut? What tool to cut?

- The use of wire saw can be sawed, if you cannot use a wire saw, it can only be used to drill holes along the need the position of the drill hole, finally use a tool to trim it to the edge.

- Q: Can aluminum profiles be used in the construction of playground equipment?

- Yes, aluminum profiles can be used in the construction of playground equipment. Aluminum is a lightweight and durable material that is resistant to corrosion, making it an ideal choice for outdoor applications such as playground equipment. It offers strength and stability while being easy to work with, allowing for the creation of various structures and designs. Additionally, aluminum profiles can be customized to meet specific requirements, ensuring the safety and functionality of the playground equipment. Overall, the use of aluminum profiles in playground equipment construction provides a reliable and long-lasting solution.

- Q: What are the different types of anodizing options for aluminum profiles?

- Aluminum profiles can be anodized in several ways, each with its own benefits and characteristics. Here are some commonly used types of anodizing: 1. Chromic Acid Anodizing (Type I): This process creates a thin, non-decorative layer that offers excellent corrosion resistance. It is often used as a primer for paints or adhesives. 2. Sulfuric Acid Anodizing (Type II): This is the most widely used anodizing process, resulting in a thicker and more durable oxide layer. It has two subtypes: regular sulfuric anodizing, which provides good corrosion resistance and can be dyed in different colors, and hardcoat anodizing, which produces a very hard and wear-resistant surface suitable for high abrasion applications. 3. Sulfuric Acid Hardcoat Anodizing (Type III): Also known as hard anodizing, this specialized process creates an even thicker and denser oxide layer than regular sulfuric anodizing. It offers enhanced wear and corrosion resistance, making it ideal for harsh environments. 4. Boric-Sulfuric Acid Anodizing (Type IV): This newer process combines sulfuric acid anodizing with a boric acid bath. It produces a thin and hard oxide layer with improved wear resistance and reduced electrical conductivity. 5. Phosphoric Acid Anodizing (Type V): This type of anodizing is used for specific applications that require a thin, dense, and hard oxide layer. It offers good corrosion resistance and can be dyed for aesthetic purposes. These different anodizing options for aluminum profiles provide a range of properties and appearances, making them suitable for various industries such as architecture, automotive, aerospace, electronics, and more. The choice of anodizing type depends on the specific requirements and desired outcome for the aluminum profile.

Send your message to us

China Made Extruded Aluminum Profiles for Door Extrusion Profiles

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords