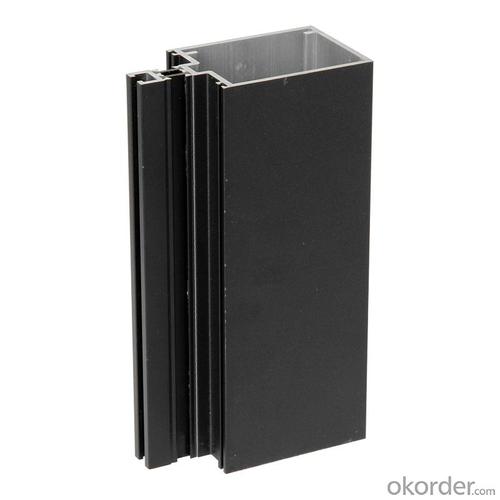

Aluminum Glazing Profiles for Window and Door Aluminium Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium profile

1) Alloy: AA6061, AA6063

2) Temper: T5, T6

3) Series of surface treament:

1. Mill Finished

2. Anodizing: Silver, champagne, light bronze, dark bronze, black, light titanium, dark titanium.

3. Electrophoretic Coating: Silver, champagne, bronze, black, light bronze, dark bronze.

4. Electrostatic Color Powder Coating: Normal color, special color.

5. Fluorocarbon Powder Spraying: Normal color, special color.

6. Wood Grain Coating: Import paper, domestic paper.

- Q: How do I choose the right aluminum profile for my project?

- When selecting the appropriate aluminum profile for your project, there are several factors that should be taken into consideration. To begin with, it is crucial to ascertain the specific needs of your project. Take into account the purpose and function of the aluminum profile, as well as any specific dimensions or specifications that must be met. This will aid in narrowing down the options and guaranteeing the selection of a profile that is suitable for your project. Next, ponder over the type of aluminum profile that would be most suitable for your project. There are various types available, such as T-slotted profiles, angle profiles, or channel profiles. Each type possesses its own advantages and applications, so it is essential to comprehend the distinctions and choose the one that best aligns with your requirements. Evaluate the strength and durability of the aluminum profile. Assess its load-bearing capacity and resistance to corrosion or other environmental factors. Depending on the nature of your project, you may require a profile that can withstand heavy loads or harsh conditions. Another crucial aspect to consider is the compatibility of the aluminum profile with other components or systems. If you intend to use the profile alongside other materials or hardware, ensure that they are compatible and can be seamlessly integrated. Furthermore, take into account the cost and availability of the aluminum profile. Compare prices from different suppliers and consider the availability of the profile in the required quantity and timeframe. Lastly, seeking expert advice or consulting with professionals who have experience working with aluminum profiles can prove to be advantageous. They can offer valuable insights and recommendations based on their knowledge and expertise. By considering these factors, you can make an informed decision and select the appropriate aluminum profile that will fulfill the specific requirements of your project.

- Q: Are aluminum profiles suitable for modular construction?

- Yes, aluminum profiles are highly suitable for modular construction. They are lightweight, yet strong and durable, making them ideal for creating modular structures. Aluminum profiles are easy to fabricate and can be easily assembled or disassembled, allowing for flexibility in design and construction. Additionally, aluminum is resistant to corrosion, which ensures the longevity of the modular construction.

- Q: Are aluminum profiles fire-resistant?

- Aluminum profiles are commonly acknowledged as being fire-resistant due to their non-combustible nature and inability to ignite or support combustion. Their high melting point of approximately 660 degrees Celsius surpasses typical fire temperatures. Nevertheless, it is crucial to acknowledge that while aluminum itself exhibits fire resistance, the accessories or components utilized alongside aluminum profiles, like gaskets or seals, may not possess the same level of fire resistance. These accessories might possess varying fire ratings, potentially influencing the overall fire resistance of the assembly. In specific scenarios, fire-resistant coatings or treatments can be applied to aluminum profiles to enhance their fire performance. These coatings offer supplementary protection and bolster the fire resistance of the profiles. To ensure fire safety in a particular application, it is always advisable to consult the manufacturer or supplier of the specific aluminum profile. They can provide insights into the profile's fire-resistant properties and suggest additional measures that can be taken to enhance fire safety.

- Q: This question asks for an overview of the typical materials used in the production of aluminum profiles.

- <p>Aluminum profiles are commonly made from various aluminum alloys, each with specific properties suited for different applications. The most common materials include 6063 aluminum alloy, known for its good mechanical properties and corrosion resistance, making it ideal for construction and industrial applications. 6061 aluminum alloy is also widely used due to its high strength-to-weight ratio and is often found in aerospace and automotive industries. Other alloys such as 6082 and 7075 are used for their superior strength and are common in heavy-duty applications. Each alloy is chosen based on the required strength, weight, and resistance to environmental factors for the intended use of the aluminum profile.</p>

- Q: Are aluminum profiles suitable for earthquake-resistant structures?

- Yes, aluminum profiles can be suitable for earthquake-resistant structures. Aluminum is a lightweight and high-strength material that offers several advantages for earthquake resistance. Firstly, its high strength-to-weight ratio allows for the construction of lighter and more flexible structures, which can better withstand seismic forces. This characteristic is particularly important as it reduces the overall mass of the structure, minimizing the inertia forces during an earthquake. Furthermore, aluminum profiles have excellent corrosion resistance, ensuring the long-term durability and structural integrity of earthquake-resistant buildings. This is crucial as corrosion can weaken the structure over time, making it more vulnerable to seismic events. In addition, aluminum's malleability allows for the creation of complex and customized profiles, enabling architects and engineers to design structures that can effectively absorb and dissipate seismic energy. This flexibility is essential in earthquake-resistant design, as it allows the structure to deform and absorb the energy generated during an earthquake, reducing the impact on the building and its occupants. Moreover, aluminum is a sustainable material, as it is highly recyclable and requires significantly less energy to produce compared to other metals. This makes it an environmentally friendly choice for earthquake-resistant structures. However, it is worth noting that the suitability of aluminum profiles for earthquake-resistant structures also depends on various factors, such as the specific design requirements, local seismic conditions, and the expertise of the engineers and architects involved. Therefore, a thorough analysis and evaluation of the specific project requirements and conditions should be conducted before determining the suitability of aluminum profiles for earthquake-resistant structures.

- Q: What are the advantages of using aluminum profiles in transportation vehicles?

- There are several advantages of using aluminum profiles in transportation vehicles. Firstly, aluminum is a lightweight material, which helps to reduce the overall weight of the vehicle. This, in turn, improves fuel efficiency and reduces emissions. Additionally, aluminum profiles offer excellent strength-to-weight ratio, providing structural integrity and safety to the vehicle. Aluminum is also corrosion-resistant, ensuring durability and longevity of the vehicle. Moreover, aluminum profiles can be easily fabricated, allowing for flexible and efficient manufacturing processes. Overall, the use of aluminum profiles in transportation vehicles brings benefits such as improved fuel efficiency, enhanced safety, and increased durability.

- Q: Can aluminum profiles be used in signage and display applications?

- Aluminum profiles are indeed applicable for signage and display purposes. With its lightweight and versatility, aluminum offers numerous advantages for these applications. Not only is it durable and resistant to corrosion, but it also has the ability to withstand various weather conditions, making it suitable for both indoor and outdoor use. Furthermore, aluminum profiles can be easily customized in terms of shape, size, and finish, enabling the creation of distinctive and captivating signs and displays. Additionally, the convenience of assembling and disassembling aluminum profiles makes transportation and installation hassle-free. In conclusion, aluminum profiles offer an excellent solution for signage and display applications due to their resilience, adaptability, and visual appeal.

- Q: Can aluminum profiles be used in sports equipment manufacturing?

- Yes, aluminum profiles can be used in sports equipment manufacturing. Aluminum is a lightweight and durable material that is commonly used in the production of sports equipment such as bicycles, tennis rackets, golf clubs, and hockey sticks. It offers excellent strength-to-weight ratio, corrosion resistance, and flexibility for design customization, making it a popular choice for many sports-related applications.

- Q: Are aluminum profiles suitable for balcony railings?

- Indeed, balcony railings can be effectively made using aluminum profiles. Aluminum is a favored material for balcony railings because it possesses qualities such as resilience, robustness, and minimal upkeep requirements. Its resistance to rust and corrosion makes it exceedingly appropriate for outdoor applications. Moreover, aluminum profiles can be effortlessly tailored and molded to match any desired design or architectural style. Although lightweight, they offer ample strength to ensure necessary support and safety for balcony railings. Additionally, aluminum railings are obtainable in a plethora of finishes and colors, providing limitless possibilities for design. On the whole, aluminum profiles are a dependable and fashionable choice for balcony railings.

- Q: What are the weatherproofing properties of aluminum profiles?

- Aluminum profiles have excellent weatherproofing properties due to their inherent resistance to corrosion and their ability to withstand extreme weather conditions. They are highly durable and can effectively protect against moisture, UV radiation, and temperature fluctuations, making them ideal for outdoor applications. Additionally, aluminum profiles can be treated with various coatings or finishes to enhance their weather resistance even further.

Send your message to us

Aluminum Glazing Profiles for Window and Door Aluminium Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords