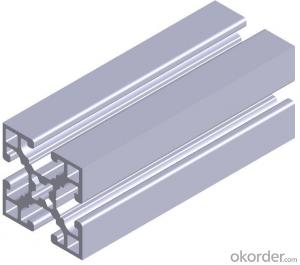

Aluminum Cladding Profiles for Heat Radiator

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Aluminum profile.heat sink profile

1.Short lead time: 7-15days.

2.professional technology supports.

3.Factory direct price

aluminum profile,industrial aluminum extrusion, construction aluminum profile

Feature:

Specification: according to your aluminum profile drawing or sample

Alloy Code: 6063-T5.6061-T6 o

Surface treatment:

Mill finish

electrophresis

Anodized(silver anodizing,bronze anodizing,champagne anodizing,etc.),

powder coating (need your confirmation by the panton colour, such as RAL9001 )

Length: no more 6.0 M

Sample time: about 13 days o

Lead time:

about 20 days for 1x40' feet

package:

Shrink film and wrapper, kraft paper ,plastic film or per client's requirement.

price: A00(SMM)+Processing fee

payment :

30% deposit +70% before the delivery or against the copy of B/L

delivery : 15-25 days after the deposit confirmed

- Q: Can aluminum profiles be used for solar panel installations?

- Yes, aluminum profiles can be used for solar panel installations. Aluminum is a commonly used material in the construction industry due to its lightweight, durability, and resistance to corrosion. These characteristics make it an ideal choice for supporting and mounting solar panels. Aluminum profiles can be easily fabricated and customized to fit specific installation requirements, such as roof or ground mounting systems. Moreover, aluminum has excellent thermal conductivity, allowing for efficient heat dissipation from the solar panels, which is crucial for maintaining their performance and lifespan. Additionally, aluminum profiles are often used for framing solar panels, providing structural support and ensuring their stability in various weather conditions. Overall, aluminum profiles are a popular choice for solar panel installations due to their strength, longevity, and adaptability.

- Q: Can aluminum profiles be used in electrical panel manufacturing?

- Yes, aluminum profiles can be used in electrical panel manufacturing. Aluminum is a lightweight and durable material that is highly conductive and resistant to corrosion, making it suitable for electrical applications. It is commonly used to construct the framework and housing of electrical panels due to its strength and ability to dissipate heat effectively.

- Q: Is it feasible to recycle aluminum profiles economically and in significant quantities?

- <p>Yes, aluminum profiles can be recycled at a reasonable cost and volume. Recycling aluminum is more cost-effective than mining and refining new aluminum from bauxite. The process requires less energy, which reduces costs. Additionally, aluminum has a high recycling rate, with about 75% of all aluminum ever produced still in use today. This indicates that aluminum recycling is both economically viable and can be done in significant volumes, contributing to sustainability and waste reduction.</p>

- Q: How to distinguish the true and false of aluminum profile

- 1. Light weight 2. 3 and after the incision is white within 4 hard, very fine very hard

- Q: Can aluminum profiles be used for solar panel mounting systems?

- Yes, aluminum profiles can be used for solar panel mounting systems. Aluminum is a popular choice for solar panel mounting systems due to its numerous advantages. Firstly, aluminum is lightweight, making it easier to handle and install. This is especially important when considering the weight that solar panels can add to a structure. Secondly, aluminum is corrosion-resistant, which is crucial as solar panel mounting systems are exposed to various weather conditions. Additionally, aluminum is a durable material that can withstand high winds, snow loads, and other environmental factors. Furthermore, aluminum profiles can be easily customized and fabricated to fit specific project requirements. They are available in various sizes and shapes, allowing for flexibility in design and installation. Overall, aluminum profiles provide a reliable and efficient solution for solar panel mounting systems.

- Q: Where is the aluminum profile market in Nanjing? Specific address, bus route

- Aluminum does not have the corresponding market basically, basically in Nanjing to do a relatively large Nanjing Meida aluminum, Nanjing Heng aluminium, yum Nanjing aluminum, Nanjing to build up the aluminum industry, basically is the nature of the company, you can go directly to their website to search their own needs aluminum.

- Q: What are the different types of fasteners used for aluminum profiles?

- There are several types of fasteners that are commonly used for aluminum profiles: 1. T-slot nuts: T-slot nuts are designed to fit into the T-slot grooves of aluminum profiles. They have a threaded hole that allows for the attachment of bolts, screws, or other fasteners. 2. Bolts and screws: Bolts and screws are used to secure aluminum profiles together or to other components. They come in a variety of lengths and sizes to accommodate different applications. 3. Corner brackets: Corner brackets are used to create strong joints between aluminum profiles at right angles. They typically have holes for screws or bolts, allowing for easy attachment. 4. T-bolts: T-bolts are similar to regular bolts, but they have a T-shaped head that fits into the T-slot grooves of aluminum profiles. This allows for quick and secure attachment without the need for nuts or additional hardware. 5. Angle brackets: Angle brackets are used to create joints between aluminum profiles at different angles. They typically have holes for screws or bolts, making it easy to secure the profiles together. 6. Clamps: Clamps are used to hold aluminum profiles in place or to attach them to other components. They come in various designs, such as lever clamps or eccentric clamps, and can be easily adjusted and tightened for a secure fit. 7. End caps: End caps are used to cover the ends of aluminum profiles, providing a finished look and protecting the profile from debris or damage. These are just a few examples of the different types of fasteners used for aluminum profiles. The choice of fastener will depend on the specific application and the desired level of strength and versatility.

- Q: This question asks for a list of various fastening methods or components used to attach aluminum profiles in roofing systems.

- <p>In roofing systems, various types of fasteners are used to secure aluminum profiles, ensuring stability and longevity. Some common fasteners include: 1. Self-tapping screws, which thread directly into the aluminum without pre-drilling. 2. Rivets, which join two pieces of aluminum by compressing them together. 3. Nuts and bolts, used in conjunction with pre-drilled holes for a secure fit. 4. Clamps, which hold profiles together without penetrating the material. 5. Adhesives, used for bonding profiles in situations where mechanical fasteners are not suitable. 6. Clips and brackets, which can be used to attach profiles to other structural elements. Each type of fastener has its specific application and is chosen based on the design requirements and environmental conditions of the roofing system.</p>

- Q: Are aluminum profiles suitable for use in mining and construction equipment?

- Yes, aluminum profiles are suitable for use in mining and construction equipment. Aluminum offers a unique set of properties that make it highly suitable for these industries. Firstly, aluminum is lightweight, which helps in reducing the overall weight of the equipment, making it easier to transport and maneuver on construction sites or in mining operations. This lightweight nature also allows for increased fuel efficiency, reducing operational costs. Additionally, aluminum profiles have excellent corrosion resistance, which is crucial in these industries where equipment may be exposed to harsh weather conditions or corrosive substances. This resistance to corrosion ensures that the equipment remains durable and long-lasting, even in challenging environments. Furthermore, aluminum profiles can be easily fabricated and customized to suit specific requirements. This flexibility in design allows for the creation of complex shapes and structures, enabling the construction of equipment with optimal strength and functionality. Moreover, aluminum profiles have high thermal conductivity, which effectively dissipates heat generated during mining and construction operations. This property is essential in preventing overheating or damage to the equipment and ensures efficient performance even in intense working conditions. Overall, the combination of lightweight, corrosion resistance, versatility, and thermal conductivity makes aluminum profiles a suitable choice for use in mining and construction equipment.

- Q: The company must tender, but it needs material certification, but what do not know exactly?

- Enterprise legal person business license, China Quality Association approved, the national industrial product production permit, 9001 certificate, a copy of tax registration certificate. Surely that will be enough

Send your message to us

Aluminum Cladding Profiles for Heat Radiator

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords