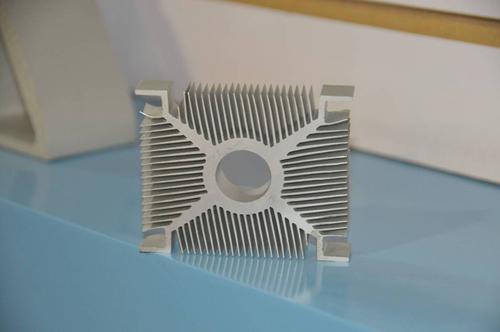

Aluminum Corner Extrusion Profiles for Industrial Field Equipment Chilling

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Aluminum extrusion radiator profile for industry field equipment chilling

1. Usage: Industrial radiator

2. Surface:Anodizing, Powder coating, Electrophoresis

3. Alloy:6063

4. Size:according to customer’s requirement

5. Advantage:Durability, good corrosion resistance and lightweight

6. Package:Normal paper package and soft plastic interleaving each profile to protect the surface. In case of any special package, additional packing cost will be charged.

- Q: Can aluminum profiles be used in the construction of data centers?

- Yes, aluminum profiles can be used in the construction of data centers. Aluminum profiles have several advantages that make them suitable for use in this industry. Firstly, aluminum is lightweight yet strong, making it an ideal material for constructing structures that need to support heavy loads. Data centers often house racks of servers and other equipment, so using aluminum profiles can provide the necessary strength without adding excessive weight. Secondly, aluminum profiles are highly customizable and can be easily fabricated to meet specific design requirements. This flexibility allows for efficient use of space within a data center, as the profiles can be tailored to fit the layout and dimensions of the facility. Additionally, aluminum is resistant to corrosion, which is crucial in a data center environment where equipment generates heat and humidity levels can be high. By using aluminum profiles, the risk of rust and corrosion is minimized, ensuring the longevity and reliability of the infrastructure. Furthermore, aluminum is a sustainable and recyclable material, which aligns with the growing demand for environmentally friendly construction practices. Using aluminum profiles in data center construction contributes to reducing the carbon footprint of the facility. In summary, aluminum profiles can indeed be used in the construction of data centers due to their strength, customization capabilities, resistance to corrosion, and sustainability.

- Q: Can aluminum profiles be recycled and reused for interior wall cladding purposes?

- <p>Yes, aluminum profiles can be recycled and reused in interior wall cladding applications. Aluminum is a highly recyclable material, and its recycling process does not degrade its properties, making it an excellent choice for sustainable construction. Recycled aluminum profiles can be used to create new wall cladding systems, reducing waste and the environmental impact of mining and processing new aluminum. This practice not only conserves natural resources but also contributes to energy savings and a lower carbon footprint.</p>

- Q: Can aluminum profiles be used for electrical cabinets?

- Yes, aluminum profiles can be used for electrical cabinets. Aluminum is a lightweight and durable material that offers excellent corrosion resistance and electrical conductivity, making it suitable for use in electrical cabinets. Additionally, aluminum profiles can be easily customized and fabricated to meet specific design and functional requirements of electrical cabinets.

- Q: What are the weight limitations of aluminum profiles?

- The weight limitations of aluminum profiles vary depending on their dimensions, thickness, and overall structural design. However, in general, aluminum profiles can support significant loads due to the strength and durability of the material. It is best to consult with the manufacturer or engineer to determine the specific weight limitations based on the intended application and structural requirements.

- Q: the middle of the following is a groove structure, as if you can not bolt hole, then how to install the rail on it? What's the use of flat sealing strips and slip bars embedded inside? Is it necessary to mount the guide rail on the aluminum profile, you can choose more than 6060 of the profiles, the middle is flat structure, and then drill holes in the bolt connection rail Thanks

- Use the T nuts (in the T groove) to fit the rail! Flat sealing strips and slip bars are embedded inside for dust proof, waterproof, oil proof and so on!!!Satisfaction, please adopt

- Q: What are the minimum thickness specifications for aluminum alloy door and window profiles?

- The main force member without the minimum wall thickness of aluminum profile measured door surface treatment not less than 2, the window is not less than 1.4, piecing material, horizontal and vertical should be determined through calculation, please refer to the specific GB8478:2008 Aluminum Alloy "window"

- Q: What are the different types of surface coatings for aluminum profiles?

- Aluminum profiles can be coated with various types of surface coatings, each possessing unique characteristics and benefits. 1. Anodizing: A popular method involves creating a protective oxide layer on the aluminum's surface. This not only enhances the profile's appearance but also improves its resistance to corrosion, wear, and scratches. Anodized aluminum profiles can be further enhanced through color dyeing or other finishing techniques. 2. Powder coating: This dry finishing process entails applying a powdered coating material to the aluminum profile. The powder, which is electrostatically charged, is then heated to form a durable and attractive coating. Powder coating provides excellent protection against scratches, UV rays, and chemical damage, making it a preferred choice for outdoor applications. 3. Liquid paint coating: Aluminum profiles can also be coated with liquid paint. In this method, the profile is either sprayed or dipped into a liquid paint solution, which is then cured to form a tough and durable finish. Liquid paint coatings offer a wide range of color options and can be customized to meet specific aesthetic requirements. 4. PVDF coating: A high-performance coating material called polyvinylidene fluoride (PVDF) is used to achieve exceptional resistance to weathering, fading, and corrosion. Typically applied through a liquid paint process, PVDF coatings can create long-lasting and vibrant finishes on aluminum profiles, particularly in architectural applications. 5. E-coating: Also known as electrophoretic deposition (EPD), this method involves immersing the aluminum profile in a bath of paint or coating solution and applying an electric current to uniformly deposit the paint onto the surface. E-coating provides excellent coverage and adhesion, making it suitable for complex-shaped profiles. It also offers good corrosion resistance and can serve as a primer before applying other coatings. Ultimately, the choice of surface coating for aluminum profiles depends on specific application requirements, including desired appearance, durability, corrosion resistance, and environmental factors. Each type of coating has its own advantages and limitations, necessitating careful consideration of these factors before making a selection.

- Q: How do you prevent galvanic corrosion in marine environments with aluminum profiles?

- One way to prevent galvanic corrosion in marine environments with aluminum profiles is by using sacrificial anodes made of a different, more active metal. These anodes, typically made of zinc or magnesium, are connected to the aluminum profiles and act as a sacrificial material that corrodes instead of the aluminum. This helps in protecting the aluminum profiles from galvanic corrosion. Additionally, proper insulation and coating of the aluminum profiles can also be effective in preventing direct contact with other metals and reducing the risk of galvanic corrosion.

- Q: How do aluminum profiles perform in terms of corrosion resistance?

- The outstanding corrosion resistance of aluminum profiles is well-known, attributed to the formation of a protective oxide layer on the surface. This oxide layer effectively shields against corrosion, even in challenging environments, acting as a barrier to halt further oxidation and corrosion. Moreover, the corrosion resistance of aluminum profiles can be further improved through diverse surface treatments like anodizing or powder coating, offering supplementary defense against corrosion. Consequently, aluminum profiles possess remarkable corrosion resistance, rendering them ideal for a vast array of applications in industries such as construction, transportation, and manufacturing.

- Q: Can aluminum profiles be subjected to painting or coating processes to enhance their aesthetic appeal and longevity?

- <p>Yes, aluminum profiles can be painted or coated to improve their appearance and durability. The process usually involves cleaning the aluminum to remove any contaminants, followed by a conversion coating to enhance adhesion. After that, a primer is applied, and finally, the paint or coating is applied. This not only enhances the visual appeal but also protects the aluminum from corrosion and wear, extending its lifespan.</p>

Send your message to us

Aluminum Corner Extrusion Profiles for Industrial Field Equipment Chilling

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords