4x8 Sheets of 5052 Aluminum - High Quality Aluminium Stucco Embossed Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminium Stucco Embossed Plate Description:

Aluminium Stucco Embossed Plate are widely used for building use, decoration use, making cookware, busing making, shipping building, airplane making and so on。Sizes of aluminum sheet for decoration use: Thickness: 0.3mm~300mm Width: Under 2000mm ( Standard: 1000mm, 1219mm, 1500mm, 1540mm) Length: Under 10000mm. Products commonly used in signs, billboards, building exterior decoration, bus body, high factory wall decoration, kitchen sink, lamp, fan, electronic components, chemical apparatus, sheet processing, deep drawing or spinning hollow ware, welding parts, heat exchangers, Bell surface and plate, plates, kitchen utensils, accessories, safety equipment and other.

2.Main Features of Aluminium Stucco Embossed Plate:

1)Light

2)Corrosion-resistant

3) The mechanical intensity is high

4) The conducting rate is high

5)The reflecting rate is high.

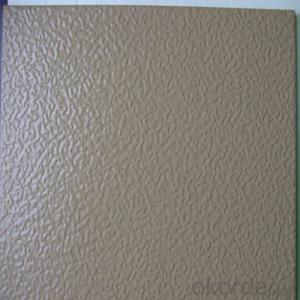

3. Aluminium Stucco Embossed Plate Images:

4. Aluminium Stucco Embossed Plate Specification:

| Aluminium sheet | |||||

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: What will affect the performance of the aluminum ingot in the process of casting?

- We all know that in 50s our technical standards are from the former Soviet Union, "A00" is the national standard in the Soviet Russian brand, "A" is the Russian alphabet, rather than English "A" word, nor the Chinese phonetic alphabet "A" and the international community, "said standard aluminum is more precise. Standard aluminium is the aluminum ingot containing 99.7% aluminium, which is registered in the London market.

- Q: Can aluminum sheets be used for chemical storage containers?

- Yes, aluminum sheets can be used for chemical storage containers. Aluminum is a corrosion-resistant metal that can withstand the chemical reactions of various substances, making it suitable for storing a wide range of chemicals. Additionally, aluminum is lightweight, durable, and easily formable, making it a practical choice for manufacturing chemical storage containers.

- Q: Are aluminum sheets resistant to UV radiation?

- Yes, aluminum sheets are highly resistant to UV radiation.

- Q: I have tried every possible method that I could find on the web for cleaning aluminum, tungsten, filler wire. Nothing has seemed to work. I've tried looking for leaks in the argon line. I'm getting decent welds but there is gunk in the welds for sure. I'm worried about overall strength of the welds. Does anybody out there know of a tried and true method for cleaning aluminum, tungsten, filler etc. that is sure to work? If I can follow that method and still have problems It could possibly be a problem with the machine. Any help would be much appreciated.

- Preweld cleaning requires two operations: oil/grease removal and oxide removal. As below, remove oils and greases first, then remove the oxide. Don’t reverse this order. Take the following steps before welding aluminum: 1. Remove oil, grease, and water vapor using an organic solvent such as acetone or a mild alkaline solution like a strong soap. You may also use citrus-based degreasers, but be sure to rinse and dry the part before welding. 2. Remove surface oxides with a stainless steel wire brush (used only for aluminum) or strong alkaline or acid. Many welding suppliers sell oxide-removal solutions in spray or squeeze bottles for local application. Exercise extreme care when handling these solutions, and again, rinse and dry the part before welding. 3. Assemble the joint. If it won't be welded immediately, cover the joint with brown Kraft paper to prevent dirt and grit in the air from getting into the joint. 4. Keep the aluminum dry and at room temperature. 5. Weld within a few days. Clean the joint again if it isn't welded within that time. Good luck!!!

- Q: What are the different packaging options available for aluminum sheets during transportation?

- There are several packaging options available for aluminum sheets during transportation. Some common methods include wrapping the sheets in protective film or paper, using wooden crates or pallets to stack and secure the sheets, and using cardboard or plastic edge protectors to prevent damage. Additionally, aluminum sheets can also be packaged in custom-cut foam or bubble wrap for added cushioning and protection during transit.

- Q: Aluminum does not react with oxygen.Aluminum is a very unreactive metal.Aluminum forms a tough protective coating with oxygen.Aluminum tarnishes instead of corroding.If you could explain why it would be helpful!

- Aluminum forms a tough protective coating with oxygen. The coating of aluminum oxide is not porous enough to let further oxygen through it, so the aluminum underneath is protected from further corrosion.

- Q: Can aluminum sheets be anodized in different finishes?

- Different finishes can be achieved when anodizing aluminum sheets. Anodizing, an electrochemical process, enhances the natural oxide layer on aluminum, increasing its thickness and durability. It is possible to customize this process to achieve clear, colored, or textured surfaces. The finish type relies on factors such as alloy composition, anodizing technique, and desired appearance. Due to their corrosion resistance, aesthetic appeal, and ability to maintain color over time, anodized aluminum sheets find extensive use in architecture, automotive, and electronics industries.

- Q: I have some carbon arrows for my bow but I was wondering if aluminum arrows penetrate farther into a deer because they weigh more. I read somewhere that they do but I just wanted to confirm that.

- Aluminum arrows do not penetrate nearly as well as the carbon arrows do. The carbon arrows penetrate better due to the carbon arrow generating more speed then the aluminum arrow and the stiffness of the carbon arrow plays a factor in it's superior penetration. If you watch a slow motion video of an aluminum arrow striking a target, the arrow flexes several times upon impact. This absorbs some of the force of the arrow. Carbon on the other hand has almost zero flex when hitting the target, therefore all the power goes into Penetration. Another fact I found out when I made the switch to carbon arrows.They are actually cheaper to use then the aluminum.A dozen carbon arrows will last much longer then a dozen aluminum ones will.You can make an aluminum arrow worthless as a hunting shaft with a broad head on it by merely dinging it a little while target practicing.Or if it becomes bent even if unable to see with the naked eye will ruin it for use with a broad head. Carbon on the other hand will never bend or ding.They last forever unless a deer rolls over on it and breaks it. It took me forever to make the switch to carbon arrows, but once I did I will never go back to aluminum again.In the old days everyone thought that weight alone was the contributing factor to penetration. But now it has been discovered that speed and stiffness are even greater factors that contribute to penetration. Stick with the carbons.

- Q: (2) when aluminium foil is dipped in mercury for a short time and then placed in water a reaction is seen to occur with hydrogen gas being one of the products.?????

- Aluminium is very reactive in air and forms a protective oxide coating. This protects it when placed in water as aluminium oxide is unreactive with water. When immersed in mercury the oxide coating is removed and therefore the aluminium itself reacts when the cleaned aluminium metal is immersed in water.

- Q: Can aluminum sheets be plasma cut?

- Indeed, aluminum sheets are able to undergo plasma cutting. The technique of plasma cutting presents itself as a versatile and highly effective method capable of cutting various materials, including aluminum, with great efficiency. By utilizing a high-speed stream of ionized gas, commonly referred to as plasma, the aluminum sheet can be meticulously shaped and tailored to meet specific requirements. Plasma cutting boasts a multitude of advantages, such as faster cutting speeds, more precise cuts, and significantly reduced heat-affected zones, in contrast to traditional cutting methods. As a result, it has become a widely utilized technique in numerous industries, including automotive, aerospace, and construction, for the purpose of cutting aluminum sheets of varying thicknesses.

Send your message to us

4x8 Sheets of 5052 Aluminum - High Quality Aluminium Stucco Embossed Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords