Sheets of Aluminum 4x8 - High Quality Aluminium Thick Sheet for Ships AA5052

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminium Thick Sheet for Ships AA5052 Description:

Plastic Film Coated Aluminum Sheets are widely used for building use, decoration use, making cookware, busing making, shipping building, airplane making and so on。Sizes of aluminum sheet for decoration use: Thickness: 0.3mm~300mm Width: Under 2000mm ( Standard: 1000mm, 1219mm, 1500mm, 1540mm) Length: Under 10000mm. Products commonly used in signs, billboards, building exterior decoration, bus body, high factory wall decoration, kitchen sink, lamp, fan, electronic components, chemical apparatus, sheet processing, deep drawing or spinning hollow ware, welding parts, heat exchangers, Bell surface and plate, plates, kitchen utensils, accessories, safety equipment and other.

2.Main Features of Aluminium Thick Sheet for Ships AA5052:

Be free from Oil Stain, Dent

Accurate tolerance

Nice mechanical property

High Quality

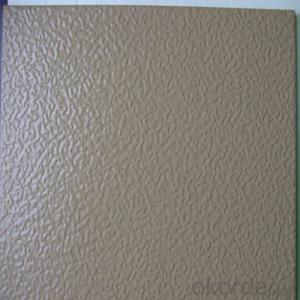

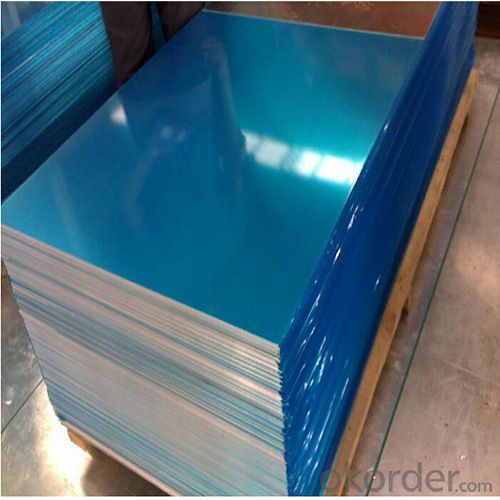

3. Aluminium Thick Sheet for Ships AA5052 Images:

4. Aluminium Thick Sheet for Ships AA5052 Specification:

Aluminum Alloy Grade | 5005 5052 5754 5083 |

| Pattern | H14 H16 H18 H24 H26 HO |

| Thickness | 0.8mm~200mm |

| MOQ | 8 tons |

| Packing | Waterproof film,kraft paper,wooden pallet and so on |

| Usage | LED Light Solar reflector plate Architectural appearance Indoor decoration: ceiling, curtain wall Furniture Elevator Index tag Case and bag Decoration in car Household appliances Boat and ship |

5.FAQ

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process..

- Q: Is it possible to use aluminum sheets in environments with high temperatures?

- <p>Yes, aluminum sheets can be used in high-temperature environments, but with certain considerations. Aluminum has a high melting point of around 660掳C (1220掳F), which allows it to withstand high temperatures. However, its mechanical properties can degrade over time when exposed to sustained high temperatures, especially above 200掳C (392掳F). For applications requiring long-term exposure to high temperatures, special heat-resistant aluminum alloys or coatings may be necessary to maintain structural integrity and performance. It's also important to consider the specific conditions and the maximum temperature the aluminum will be exposed to when determining its suitability for a high-temperature application.</p>

- Q: What is the price range of aluminum sheets?

- The price range of aluminum sheets can vary depending on factors such as size, thickness, and quality. However, generally speaking, aluminum sheets can range in price from $1 to $5 per square foot.

- Q: What are the different methods of surface finishing for aluminum sheet?

- Aluminum sheets can undergo various surface finishing methods, each with its own distinct characteristics and advantages. Some commonly used methods include anodizing, painting, powder coating, polishing, and brushing. Anodizing is a widely employed technique that forms a protective oxide layer on the aluminum's surface. This process not only enhances the sheet's appearance but also improves its resistance to corrosion and durability. Anodized aluminum sheets are available in different colors and finishes, making them suitable for diverse applications. Painting is another frequently used method where a layer of paint is applied to the aluminum sheet to provide both decorative and protective coating. This approach allows for a wide range of colors and finishes, enabling customization and design versatility. Moreover, painting can enhance the sheet's resistance to weathering and scratches. Powder coating involves applying a dry, powdered coating to the aluminum sheet, which is then heated to create a durable and uniform layer. This technique offers excellent protection against corrosion, chemicals, and UV rays, making it ideal for applications requiring high durability and weather resistance. Polishing is a surface finishing method that employs abrasive materials to create a smooth and shiny surface on the aluminum sheet. This technique is commonly used to enhance the sheet's aesthetic appeal by eliminating imperfections and scratches. Polished aluminum sheets are often used in decorative applications where a reflective and lustrous surface is desired. Brushing is a process that gives the aluminum sheet a textured surface using abrasive brushes or pads. This method creates parallel lines or patterns on the sheet, resulting in a distinctive and attractive appearance. Brushed aluminum sheets find applications in architectural and interior design, as well as in the manufacturing of household appliances and automotive components. In conclusion, the various surface finishing methods for aluminum sheets offer a range of options to enhance their appearance, durability, and functionality. Whether it is anodizing, painting, powder coating, polishing, or brushing, each method brings unique benefits that can be tailored to specific applications and design requirements.

- Q: I am looking for info on grades of aluminum like 3003, 5053, 6160 what's the differance witch one are cheaper and weld easy please explain

- 1) okorder /

- Q: Can aluminum sheets be embossed or textured?

- Aluminum sheets are indeed capable of being embossed or textured. To achieve this, specialized machinery is employed to press or roll the sheet, thereby creating patterns or designs on its surface. The purpose of embossing or texturing aluminum sheets can be twofold: enhancing the sheet's aesthetic appeal or enhancing its functionality by providing grip or augmenting its strength. These embossed or textured aluminum sheets find widespread usage across different industries, including automotive, interior design, and packaging.

- Q: Can aluminum sheets be bent or formed without cracking or breaking?

- Yes, aluminum sheets can be bent or formed without cracking or breaking, but it depends on the thickness of the sheet and the method used for bending or forming. Aluminum is a highly malleable metal, which means it can be easily bent or formed into various shapes without breaking. However, if the sheet is too thin or the bending or forming process is done without proper care or precision, there is a risk of cracking or breaking. To avoid this, it is important to use appropriate tools and techniques, such as using a bending brake or a rolling machine, and ensuring that the sheet is not subjected to excessive force or stress during the process. Additionally, annealing the aluminum sheet before bending or forming can increase its flexibility and reduce the chance of cracking. Overall, with the right approach and precautions, aluminum sheets can be successfully bent or formed without cracking or breaking.

- Q: Is this aluminium plate ceiling dark keel or bright keel?

- I see you're a layman...... Where is the ceiling keel now?.... Now they are made of dark keel, so it's better to look at comfort, and we need to go through the lines and some pipes

- Q: A solid aluminum sphere has a mass of 83 g.Use the density of aluminum to find the radius of the sphere in inchesExpress your answer using two significant figures.I can't figure this out :(

- Aluminum has a density of 2.702 g/cm^3. 83 g x (1 cm^3 / 2.702 g) = 30.7 cm^3 That's the volume of the Al sphere. The formula for the volume of a sphere is V = (4/3)(pi)(r^3) where r is the radius. 30.7 = (4/3)(3.1416)((r^3) 7.33 = r^3 1.94 cm = r 1.94 cm x (1 in / 2.54 cm) = 0.76 inches.

- Q: What is the typical thickness tolerance for aluminum sheets?

- The typical thickness tolerance for aluminum sheets can vary depending on the specific grade and manufacturing process, but it is generally around ±0.005 to ±0.01 inches.

- Q: What are the different methods for engraving aluminum sheets?

- There are several different methods for engraving aluminum sheets, each with its own advantages and applications. 1. Laser engraving: This is one of the most popular methods for engraving aluminum sheets. It uses a laser beam to vaporize the aluminum surface, creating a permanent and precise engraving. Laser engraving offers high precision, speed, and versatility, making it suitable for a wide range of applications. 2. Mechanical engraving: This method involves using a mechanical tool, such as a rotary cutter or diamond-tipped tool, to physically remove material from the aluminum surface. Mechanical engraving can achieve deep and detailed engravings, making it suitable for applications where durability and depth are important. 3. Chemical etching: Chemical etching involves using chemicals to selectively remove material from the aluminum surface. It is a highly precise method that can create intricate and detailed designs. Chemical etching is often used in industries such as electronics and aerospace, where precision and high-quality finishes are required. 4. CNC milling: Computer Numerical Control (CNC) milling is a method that uses a computer-controlled machine to remove material from the aluminum sheet. It can achieve precise and complex engravings, making it suitable for applications that require intricate designs or 3D engravings. 5. Hand engraving: Hand engraving involves using handheld tools, such as gravers or chisels, to manually create engravings on the aluminum surface. While it may not offer the same level of precision as other methods, hand engraving allows for artistic freedom and customization. Each method has its own advantages and limitations, so the choice of engraving method depends on factors such as the desired design, level of detail, production volume, and budget.

Send your message to us

Sheets of Aluminum 4x8 - High Quality Aluminium Thick Sheet for Ships AA5052

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords