Wholesale Sublimation Aluminum Sheets for Semi-Unitized Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminium Sheets for Semi-Unitized Curtain Wall

Aluminium Sheets for Semi-Unitized Curtain Wall are one type of non-frame curtain wall than consist of glass panels, point-fixing components on such panels and their supporting structures. .

Aluminium Sheets for Semi-Unitized Curtain Wall are good at ductility, heat conductivity, anti-corrosion and moisture resistance. They are widely used in roofing, electronics, instruments, lighting decoration, packing, decoration, curtain wall, sandwich panels, boats, etc.

2.Main Features of Aluminium Sheets for Semi-Unitized Curtain Wall

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

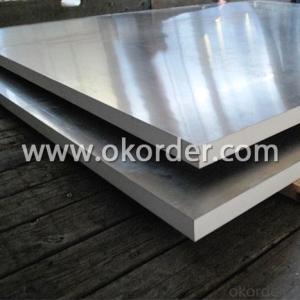

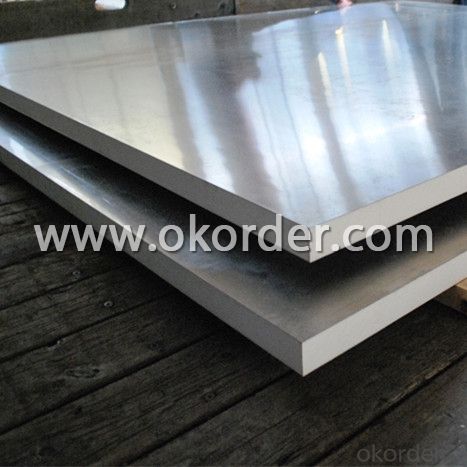

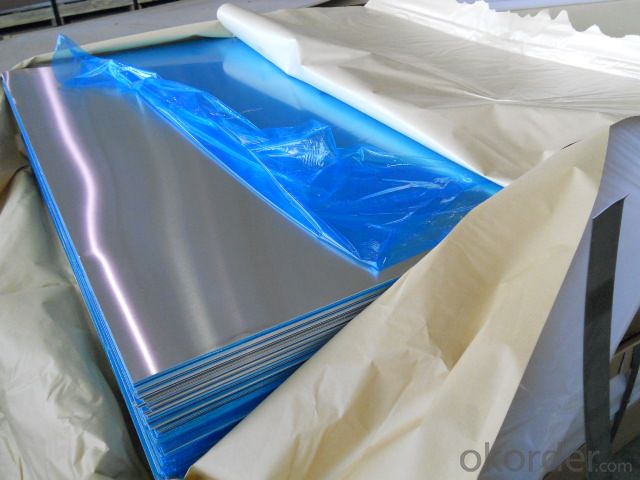

3. Aluminium Sheets for Semi-Unitized Curtain Wall Images

4.Specification of Aluminium Sheets for Semi-Unitized Curtain Wall

Alloy | AA1050,AA1060, AA1070, AA1100 |

Temper: | H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness: | 0.10-500mm |

Width: | 10mm- 2200mm |

Standard: | GB/T3880-2006, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement | |

5.FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: Can someone please help me with the resonance structure for AlCl3. When I draw it, the central Al does not have a complete octet. I read that this is usually the case for atoms like Boron and Aluminium who only have three valence electrons. Is this correct? Also, as a follow on question, does AlCl3 display resonance?

- Since aluminum only has 3 valence electrons it will be missing two electrons from its octet. This means that one of the chloride groups must share an extra electron group with the aluminum. Any three of the chlorides can share an extra electron pair with it (i.e. they'll have 2 lines attached to aluminum), so there is resonance. There are 3 to be specific, one for each chloride sharing another electron pair with Al.

- Q: Are aluminum sheets suitable for outdoor use?

- Yes, aluminum sheets are suitable for outdoor use. Aluminum is a durable and corrosion-resistant material that can withstand various weather conditions, making it ideal for outdoor applications.

- Q: What are the different methods of joining aluminum sheets without welding?

- There are several methods of joining aluminum sheets without welding, including adhesive bonding, mechanical fastening (such as screws or rivets), clinching, and using non-welding techniques like friction stir welding or laser welding.

- Q: What are the common uses of aluminum sheets?

- Aluminum sheets possess excellent properties, rendering them highly versatile and extensively utilized across various industries. Their applications encompass: 1. Construction: In the construction industry, aluminum sheets find common usage for roofing, siding, and insulation purposes. Their lightweight nature, durability, and resistance to corrosion make them ideal for shielding against the elements. 2. Transportation: The automotive and aerospace industries heavily rely on aluminum sheets. These sheets contribute to the manufacturing of car bodies, truck trailers, and aircraft parts owing to their impressive strength-to-weight ratio. Consequently, the utilization of aluminum sheets aids in enhancing fuel efficiency and reducing overall vehicle weight. 3. Packaging: Aluminum sheets serve as a popular choice for packaging purposes, specifically within the food and beverage industry. Cans, foils, and containers are frequently crafted from aluminum sheets, as they effectively safeguard packaged products by acting as barriers against moisture, light, and oxygen. 4. Electrical and Electronics: The electrical and electronics industry benefits from the application of aluminum sheets due to their exceptional conductivity. Their utilization extends to the manufacturing of electrical enclosures, heat sinks, and wiring, as they efficiently dissipate heat and protect delicate electronic components. 5. Marine Industry: Aluminum sheets hold significant value within the marine industry due to their resistance to corrosion. They are employed in the construction of boat hulls, ship fittings, and other marine equipment. The ability of aluminum sheets to withstand harsh marine environments, alongside their lightweight properties, renders them an appealing choice. 6. Decorative Applications: Architectural applications often feature aluminum sheets for their aesthetic appeal. These sheets can be effortlessly shaped, formed, and colored to create diverse decorative elements like wall cladding, ceilings, and decorative panels. In conclusion, aluminum sheets serve as a fundamental material across numerous industries, including construction, transportation, packaging, electrical and electronics, marine, and decorative applications. Their versatility and significance are evident in their widespread utilization throughout various sectors.

- Q: What is the typical flammability rating of aluminum sheets?

- Aluminum sheets typically have a flammability rating of Class A. This means that they are highly resistant to fire and will not easily ignite or contribute to the spread of flames. Aluminum is a non-combustible material, making it a popular choice for various applications where fire safety is a concern, such as construction, transportation, and aerospace industries. It has a high melting point and excellent heat dissipation properties, which further enhances its fire-resistant characteristics.

- Q: will it influence powder injection effect after wiping the oil contamination on the surface of aluminum sheet?

- no, but I'm not certain.

- Q: I have tried every possible method that I could find on the web for cleaning aluminum, tungsten, filler wire. Nothing has seemed to work. I've tried looking for leaks in the argon line. I'm getting decent welds but there is gunk in the welds for sure. I'm worried about overall strength of the welds. Does anybody out there know of a tried and true method for cleaning aluminum, tungsten, filler etc. that is sure to work? If I can follow that method and still have problems It could possibly be a problem with the machine. Any help would be much appreciated.

- Preweld cleaning requires two operations: oil/grease removal and oxide removal. As below, remove oils and greases first, then remove the oxide. Don’t reverse this order. Take the following steps before welding aluminum: 1. Remove oil, grease, and water vapor using an organic solvent such as acetone or a mild alkaline solution like a strong soap. You may also use citrus-based degreasers, but be sure to rinse and dry the part before welding. 2. Remove surface oxides with a stainless steel wire brush (used only for aluminum) or strong alkaline or acid. Many welding suppliers sell oxide-removal solutions in spray or squeeze bottles for local application. Exercise extreme care when handling these solutions, and again, rinse and dry the part before welding. 3. Assemble the joint. If it won't be welded immediately, cover the joint with brown Kraft paper to prevent dirt and grit in the air from getting into the joint. 4. Keep the aluminum dry and at room temperature. 5. Weld within a few days. Clean the joint again if it isn't welded within that time. Good luck!!!

- Q: What is the maximum width available for aluminum sheets?

- The maximum width available for aluminum sheets varies depending on the supplier and the specific requirements. However, standard widths for aluminum sheets typically range from 36 inches to 72 inches.

- Q: Are aluminum sheets resistant to impact and vibration?

- Aluminum sheets, in general, show resistance to impact and vibration. The notable feature of aluminum lies in its remarkable strength-to-weight ratio, rendering it a robust and lightweight substance. With commendable mechanical properties, including outstanding resistance to impact and vibration, aluminum sheets frequently find application in various sectors necessitating protection against such forces. Take, for instance, automotive parts, aircraft structures, and building facades. Furthermore, the addition of other elements to aluminum alloys can amplify its impact resistance and diminish vibrations. To sum up, aluminum sheets prove to be a dependable option in enduring the forces of impact and vibration.

- Q: How much weight/people can a 12ft aluminum boat hold?and if anyone knows how much weight can a 6.5hp motor push around

- 12 Ft Aluminum Jon Boat

Send your message to us

Wholesale Sublimation Aluminum Sheets for Semi-Unitized Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords