DC Aluminium Strip in Coils AA3105 Temper F - Aluminum Foil Sheets 12x10.75

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 80 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

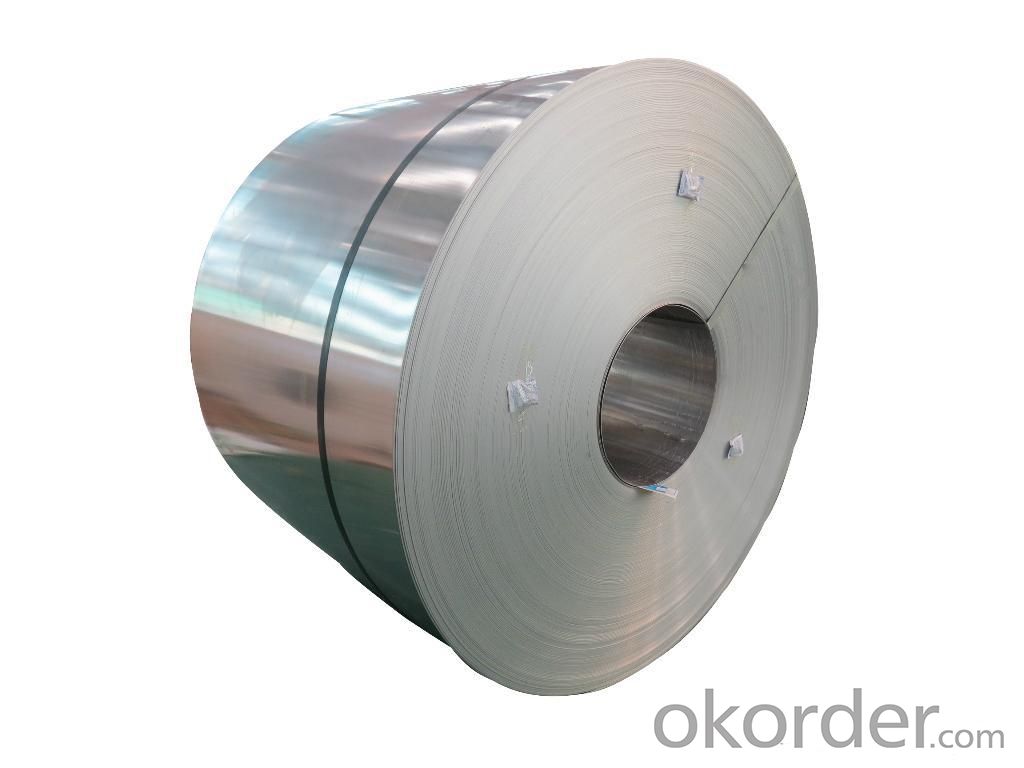

1.Structure of Product Description

DC Aluminium Strip in Coil is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA3105 is widly used in prepainted aluminium coil&sheet. Its weight is much lower than steel. The paints is domestic brand, PPG and Becker.

2. Main features of the product

a.Competitive price

b.Professional after-sale service

c.Fast delivery time

3.Image

4.Products Specification

| Alloy | Thickness | Temper | Coil Weight | Coil ID | Usage |

| AA3003 | 3-8mm | F | 5-6 MT | 610mm | Painting aluminium coil |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: This question asks for a comparison between aluminum sheets and other roofing materials in terms of their characteristics and performance.

- <p>Aluminum sheets are lightweight and highly durable, offering excellent resistance to corrosion and weathering. They are energy-efficient, reflecting heat and reducing cooling costs. Compared to materials like asphalt shingles, aluminum is more expensive but lasts longer, with a lifespan of 40-50 years. Unlike clay or concrete tiles, aluminum is less prone to breakage and is easier to install. It also doesn't rot or warp like wood, and it's fire-resistant. However, it can be noisy during rain and is less visually appealing than some other materials, but its modern and sleek appearance can be a design advantage.</p>

- Q: Are aluminum sheets resistant to rust?

- Yes, aluminum sheets are highly resistant to rust. This is because aluminum naturally forms a protective oxide layer on its surface when exposed to air, which prevents further corrosion. Unlike iron or steel, which can rust when exposed to moisture and oxygen, aluminum does not require any additional coatings or treatments to protect it from rusting. This makes aluminum sheets a popular choice for a wide range of applications, including construction, automotive, and marine industries, where resistance to rust is essential.

- Q: What is the hardness rating of 101 aluminum sheets?

- The hardness rating of 101 aluminum sheets can vary depending on several factors, such as the alloy composition, heat treatment, and manufacturing processes. However, in general, aluminum alloys are known for their relatively low hardness compared to other metals. The Rockwell hardness scale is commonly used to measure the hardness of metals, but it is not typically applied to aluminum. Instead, the Brinell or Vickers hardness tests are more commonly used for aluminum alloys. Without specific information about the alloy composition and any specific heat treatment applied to the 101 aluminum sheets, it is difficult to provide an exact hardness rating. Therefore, it is recommended to consult the manufacturer or supplier of the specific 101 aluminum sheets for accurate hardness information.

- Q: Are aluminum sheets suitable for food preparation surfaces?

- Yes, aluminum sheets are suitable for food preparation surfaces. Aluminum is a durable and lightweight material that is resistant to corrosion and easy to clean, making it a popular choice for food preparation. However, it is important to note that aluminum can react with certain acidic or salty foods, so it is recommended to use a protective barrier such as parchment paper or silicone mats when working with such ingredients.

- Q: This question asks about the various applications of aluminum sheets within the construction industry.

- <p>Aluminum sheets are widely used in construction for their durability, lightweight, and resistance to corrosion. They are commonly used for roofing and cladding due to their ability to withstand harsh weather conditions. Aluminum sheets are also used in the manufacturing of window frames and doors because of their strength and thermal insulation properties. Additionally, they are utilized in the construction of scaffolding and temporary structures due to their ease of assembly and disassembly. In interior design, aluminum sheets can be used for decorative purposes, such as wall panels and ceilings. Their recyclability also makes them an environmentally friendly choice for construction projects.</p>

- Q: What are the specific rules or benchmarks that must be followed when utilizing aluminum sheets for construction purposes?

- <p>Yes, there are special regulations and standards for using aluminum sheets in construction projects. These include material specifications, thickness, and strength requirements as per the American Society for Testing and Materials (ASTM) standards, such as ASTM B209 for aluminum sheet and plate. Additionally, the International Building Code (IBC) and local building codes provide guidelines for the use of aluminum in construction. These standards cover aspects like fire resistance, structural integrity, and weather resistance. Compliance with these regulations ensures safety, durability, and compliance with construction laws.</p>

- Q: What type of aluminum plate does it contain?

- The 3 * * * series aluminum plate is mainly composed of manganese, and the content is between 1.0-1.5%.4 * * * series aluminum sheet: stands for 4A01. The 4 * * * series aluminum plate belongs to a series with high silicon content.5 * * * series aluminum sheet: stands for 5052, 5005, 5083, 5A05 series.

- Q: What is the most efficient and low cost method for welding 1mm-3mm aluminum sheet?,What's new?

- Welding methods almost all kinds of welding methods can be used for welding aluminum and aluminum alloy, but the adaptability of aluminum and aluminum alloy to various welding methods is different, and various welding methods have their respective application. Gas welding and SMAW method, simple equipment, convenient operation. The gas can be used for welding of aluminum plate and casting of high welding quality requirements. Electrode arc welding can be used for repairing welding of aluminium alloy castings. Inert gas shielded welding (TIG or MIG) is the most widely used method for welding aluminum and aluminum alloys. Tungsten and argon arc welding or tungsten arc argon arc welding can be used for aluminum and its alloy sheets. Aluminum and aluminium alloy heavy plates can be made of tungsten helium arc welding, argon helium tungsten gas welding, MIG welding and pulse MIG welding. MIG welding and pulse MIG welding are more and more widely used (argon or argon / helium)Laser welding machine can also be used

- Q: Are aluminum sheets resistant to abrasion?

- Indeed, aluminum sheets exhibit a general resistance to abrasion. Renowned for its sturdy nature and robustness, aluminum proves impervious to scratches or harm induced by abrasion. Nevertheless, the degree of resistance may fluctuate contingent upon the particular alloy and thickness of the aluminum sheet. Sheets boasting greater thickness and higher alloy content typically offer superior protection against abrasion. Furthermore, the surface finish of the aluminum sheet can also influence its resistance to abrasion. All things considered, aluminum sheets present a dependable option for enduring abrasion in a myriad of applications.

- Q: Can aluminum sheets be used in construction?

- Yes, aluminum sheets can be used in construction. They are commonly used for roofing, siding, and structural applications due to their lightweight, corrosion-resistant, and durable properties.

Send your message to us

DC Aluminium Strip in Coils AA3105 Temper F - Aluminum Foil Sheets 12x10.75

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 80 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords