China Aluminum Oxide Sandpaper Sheets for Semi-Unitized Curtain Wall Aluminium Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

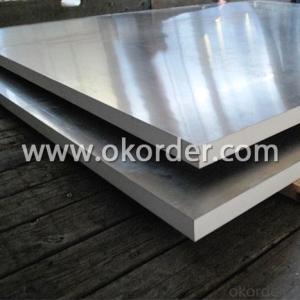

1.Structure of Aluminium Sheets for Semi-unitized Curtain Wall

Aluminium sheets for semi-unitized curtain walls have the combined features of stick curtain wall and unitized curtain wall. All components of semi-unitized curtain wall except main keels are fabricated and assembled into unitized panels.

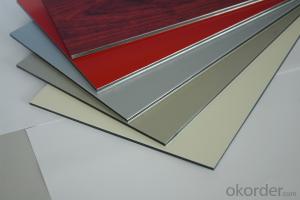

Aluminium sheets for semi-unitized curtain walls are good at ductility, heat conductivity, anti-corrosion and moisture resistance. They are widely used in roofing, electronics, instruments, lighting decoration, packing, decoration, curtain wall, sandwich panels, boats, etc.

2.Main Features of Aluminium Sheets for Semi-unitized Curtain Wall

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

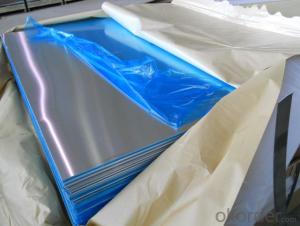

3. Aluminium Sheets for Semi-unitized Curtain Wall Images

4.Specification of Aluminium Sheets for Semi-unitized Curtain Wall

Alloy | AA1050,AA1060, AA1070, AA1100 |

Temper: | H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness: | 0.10-500mm |

Width: | 10mm- 2200mm |

Standard: | GB/T3880-2006, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement | |

5.FAQ

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: Do 101 aluminum sheets have any specific fire resistance properties?

- Yes, 101 aluminum sheets have specific fire resistance properties. Aluminum has a high melting point of 660 degrees Celsius (1220 degrees Fahrenheit), which means it can withstand high temperatures before it starts to melt. Additionally, aluminum has a low combustion point, which means it does not readily catch fire. In case of a fire, aluminum sheets act as a barrier, preventing the spread of flames. Moreover, when aluminum does burn, it forms a protective oxide layer on its surface, which further inhibits the progress of the fire. However, it is important to note that while aluminum has fire-resistant properties, it is not completely fireproof and can still be damaged or deformed by intense heat.

- Q: What types of aluminum sheets are recommended for outdoor applications?

- <p>Yes, there are specific types of aluminum sheets suitable for exterior use. These include aluminum sheets with a protective coating, such as anodized aluminum, which offers enhanced resistance to corrosion and weathering. Additionally, aluminum sheets with a Kynar 500庐 PVDF coating are highly resistant to UV rays, making them ideal for exterior applications. Marine-grade aluminum is also recommended for exterior use due to its superior corrosion resistance, especially in coastal areas. These types of aluminum sheets are designed to withstand harsh outdoor conditions and maintain their integrity over time.</p>

- Q: The question asks about the duration aluminum sheets can last and how this compares to the lifespan of other materials.

- <p>The lifespan of aluminum sheets can vary significantly based on the environment and usage conditions. Generally, aluminum sheets have a long lifespan, often lasting 50 years or more without significant deterioration when properly maintained. This durability makes aluminum sheets a popular choice for construction and manufacturing applications. Compared to other materials, such as steel, aluminum is lighter and more resistant to corrosion, which can extend its lifespan in certain environments. However, steel may be more suitable for applications requiring high strength, while aluminum excels in applications where weight and corrosion resistance are priorities.</p>

- Q: Explain how the use of aluminum sheets can impact the energy efficiency of a building.

- <p>Aluminum sheets can significantly affect a building's energy efficiency due to their excellent thermal conductivity and reflective properties. They can be used in building construction to form a barrier against heat transfer, reducing the need for heating and cooling. Additionally, aluminum's reflective surface can help in reflecting sunlight, thereby reducing heat gain in the building. However, if not properly insulated, aluminum's high conductivity can lead to heat loss, reducing energy efficiency. Therefore, the use of aluminum sheets in buildings often requires a balance between their heat-reflective and heat-conductive properties to optimize energy efficiency.</p>

- Q: Can aluminum sheet be used for medical applications?

- Certain medical applications can utilize aluminum sheet. This material is lightweight, durable, and resistant to corrosion, making it suitable for a range of medical devices and equipment. Prosthetic limbs, braces, and orthopedic implants can be manufactured using aluminum sheets. Additionally, medical instruments like surgical trays, sterilization containers, and imaging equipment can be produced using aluminum. However, it is important to consider that not all medical applications can use aluminum, as some devices may require specific properties or materials to meet regulatory standards and ensure patient safety. Therefore, the use of aluminum sheet in medical applications should be assessed on a case-by-case basis, taking into account the specific requirements and regulations of each application.

- Q: Can aluminum sheets be used for electrical busbars?

- Yes, aluminum sheets can be used for electrical busbars. Aluminum is a commonly used material for busbars due to its excellent electrical conductivity, lightweight nature, and cost-effectiveness. However, it is important to consider factors such as current carrying capacity, temperature rise, and mechanical strength when selecting aluminum sheets for busbar applications.

- Q: What are the fire resistance properties of aluminum sheets?

- Aluminum sheets exhibit excellent fire resistance properties due to their high melting point and low thermal conductivity. Aluminum has a melting point of approximately 660 degrees Celsius, which is significantly higher than other commonly used metals like steel. This means that aluminum sheets can withstand high temperatures without melting or losing their structural integrity. Additionally, aluminum has a low thermal conductivity, which means it does not transfer heat easily. This property helps to prevent the spread of fire and limits the heat transfer to adjacent areas. Moreover, aluminum does not produce toxic gases or emit hazardous fumes when exposed to fire, making it a safe material in fire-prone environments. These fire-resistant properties make aluminum sheets a popular choice for various applications where fire safety is a concern, such as in the construction of aircraft, buildings, and automotive components.

- Q: How does 1200X1200X15 6061 aluminum, CNC processing, the plane degree can reach the number of my clients to 0.2, but I used to use the MS 1000X1500X70 to the material processing, the flatness is only 1, please experienced friend to help, thank you

- The first rough machining, no precision position of the first place, finishing allowance for heat treatment of unilateral 0.15MM, and then remove the stress of 420 degrees Celsius for 4 hours, with the furnace cooling (very important), doing fine processing, can guarantee within 0.03.Is the aluminum plate with a thickness of more than 0.2mm to 500mm, 200mm width, length less than 16m aluminum material called aluminum plate or aluminum sheet, aluminum is below 0.2mm, 200mm within the width of the row material or bar (of course, with the progress of the large equipment, the width can be 600mm row material also more). Aluminum sheet refers to the rectangular plate made of aluminium ingot rolled and divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, middle thick aluminum plate and pattern aluminum plate.

- Q: Are 101 aluminum sheets suitable for cryo-treating applications?

- Indeed, cryo-treating applications can benefit from the utilization of 101 aluminum sheets. Cryo-treating encompasses the practice of exposing materials to extremely low temperatures to enhance their strength, durability, and resistance to wear. 101 aluminum, being a commercially pure alloy, boasts exceptional corrosion resistance and favorable mechanical properties. It can endure cryogenic temperatures without experiencing considerable strength degradation or any adverse consequences. As a result, the application of 101 aluminum sheets in cryo-treating endeavors can effectively yield desired advantages and augment performance.

- Q: Can aluminum sheets be used for lithographic printing?

- Yes, aluminum sheets can be used for lithographic printing. Lithographic printing, also known as offset printing, relies on the principle that oil and water do not mix. Aluminum plates are used as the printing surface in lithography because they can retain an image when treated with a combination of chemicals. The image areas attract ink, while the non-image areas repel it. This allows for high-quality and precise printing.

Send your message to us

China Aluminum Oxide Sandpaper Sheets for Semi-Unitized Curtain Wall Aluminium Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords