Powder Coated Mill Finish Aluminum Sheets for Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Aluminium Sheet for Curtain Wall

Alloy Number | AA1xxx 3xxx 5xxx |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

2. Application of Mill Finish Aluminium Sheet for Curtain Wall

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Aluminium Sheet for Curtain Wall

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

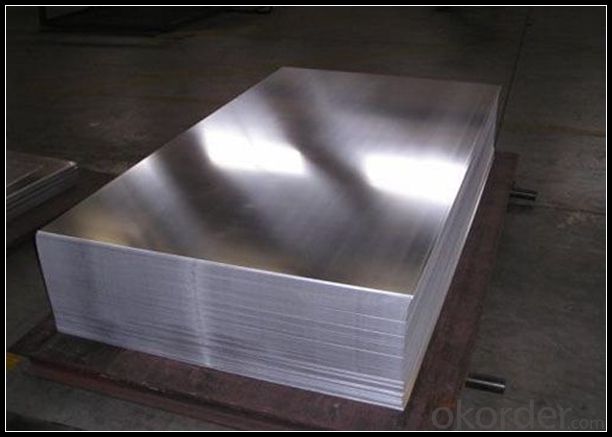

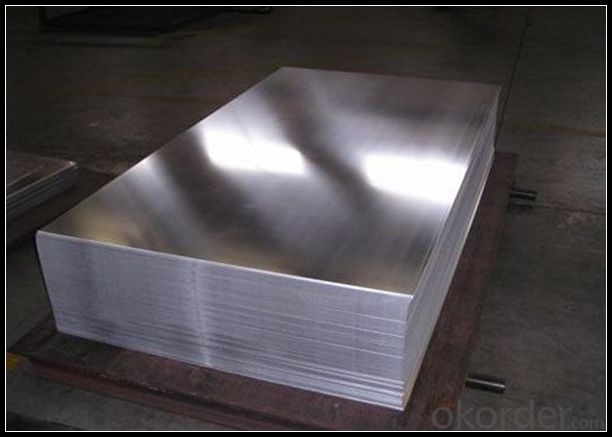

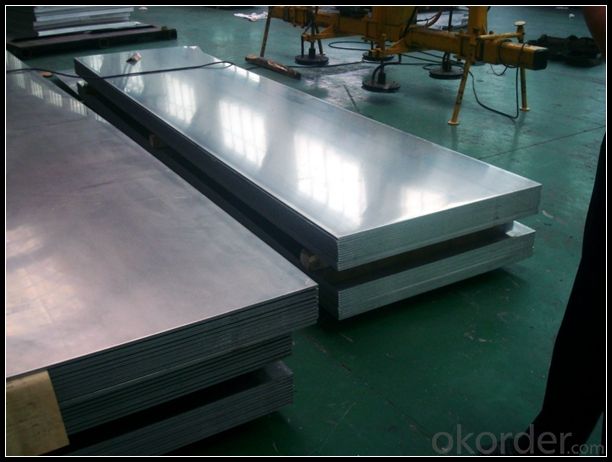

5. Image of Mill Finish Aluminium Sheet for Curtain Wall

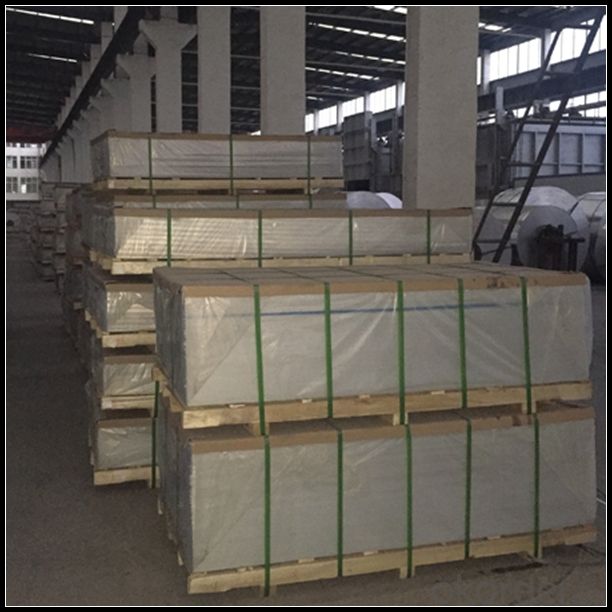

6. Package and shipping of Mill Finish Aluminium Sheet for Curtain Wall

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Is it possible to recycle aluminum sheets multiple times?

- <p>Yes, aluminum sheets can be recycled again and again. The recycling process for aluminum is highly efficient, and it can be recycled indefinitely without losing any quality. This is due to the fact that aluminum retains its properties even after multiple recycling cycles. Each time aluminum is recycled, it can be melted down and reformed into new products, making it a sustainable and environmentally friendly material.</p>

- Q: This question asks for an overview of the various types of coatings applied to aluminum profiles used in exterior cladding systems.

- <p>Aluminum profiles for exterior cladding are often coated to enhance their durability, weather resistance, and aesthetic appeal. Common types of coatings include: 1. Anodizing, which creates a protective oxide layer on the aluminum surface. 2. Powder coating, a popular method that provides a durable and colorful finish. 3. Fluorocarbon coating, known for its excellent weathering and UV resistance. 4. PVDF (Polyvinylidene Fluoride) coating, highly resistant to chemicals and suitable for marine environments. 5. Electrophoretic coating, which offers a smooth, even finish. 6. Hot-dip galvanizing, a process that coats aluminum with a protective layer of zinc. Each coating type has specific advantages and is chosen based on the performance requirements and environmental conditions of the project.</p>

- Q: How do you prevent oxidation of exposed edges of aluminum sheets?

- One effective way to prevent oxidation of exposed edges of aluminum sheets is by applying a protective coating or sealant. This creates a barrier between the aluminum and the surrounding air, preventing the metal from coming into contact with oxygen and moisture, which are the main causes of oxidation. Additionally, storing the aluminum sheets in a dry and controlled environment can also help minimize the risk of oxidation.

- Q: This question asks for methods to clean aluminum sheets to preserve their appearance.

- <p>To clean aluminum sheets and maintain their appearance, follow these steps: 1. Use a mild detergent mixed with warm water to create a cleaning solution. 2. Gently scrub the aluminum sheets with a soft cloth or sponge to avoid scratching the surface. 3. Rinse thoroughly with clean water to remove any detergent residue. 4. Dry the sheets immediately with a soft, dry cloth to prevent water spots. 5. For stubborn stains, use a non-abrasive cleaner specifically designed for aluminum. 6. Avoid using harsh chemicals or abrasive materials that can damage the aluminum's finish. Regular cleaning will help preserve the appearance and longevity of aluminum sheets.</p>

- Q: What are the various types of insulation materials that can be combined with aluminum sheets for thermal or acoustic insulation purposes?

- <p>There are several types of insulation that can be used in conjunction with aluminum sheets, including: 1. Polyurethane foam, which provides excellent thermal insulation and can be bonded to aluminum sheets. 2. Mineral wool, a fire-resistant material that offers both thermal and acoustic insulation. 3. Polyisocyanurate, known for its high R-value and can be laminated to aluminum for added strength. 4. Extruded polystyrene, which is lightweight and provides good thermal resistance. 5. Fiberglass, a versatile insulation material that can be combined with aluminum for various applications. Each type has its specific properties and applications, making them suitable for different environments and insulation needs.</p>

- Q: How is the thickness of an aluminum sheet measured?

- The thickness of an aluminum sheet is typically measured using a tool called a micrometer. This handheld device applies pressure to the sheet and displays the measurement in millimeters or inches on a digital or analog gauge.

- Q: How to polish aluminum sheet to be bright?

- as for polishing, fine grit sandpaper can't polish it into a mirror,but laser cutting can do it.

- Q: Are aluminum sheets resistant to staining?

- Yes, aluminum sheets are generally resistant to staining due to their natural ability to form a protective oxide layer on the surface, which prevents corrosion and staining.

- Q: What are the different methods of surface preparation for adhesive bonding of aluminum sheet?

- There are several different methods of surface preparation for adhesive bonding of aluminum sheet. These methods include mechanical abrasion, chemical etching, and surface treatments such as anodizing or conversion coating. Mechanical abrasion involves roughening the surface of the aluminum sheet using sandpaper or other abrasive materials to improve adhesion. Chemical etching involves using acid or alkaline solutions to create a textured surface on the aluminum sheet. Surface treatments such as anodizing or conversion coating involve applying a protective layer or coating to the aluminum sheet to enhance adhesion. Ultimately, the choice of surface preparation method depends on the specific requirements of the adhesive bonding process and the type of adhesive being used.

- Q: I don't know if the electrons are being passed from my hand to the aluminum or from the aluminum to my hand.Thanks

- Aluminum is a metal and every metal has a property that it holds electrons of its outer most orbital quite loosely ( it is electropositive ). And our hand's skin consists of mostly COVALENT bonded compounds which hold their electrons quite tightly. So if we touch aluminum the chances are strong that the electrons are being transferred from aluminum to our hands. But since our hand have covalent compounds so the total transfer must be very small if it is anyway. Otherwise we feel shock every time we touch a neutral aluminum also IF U develop some negative charge then aluminum will take that charge since it has small hold on the outermost electrons. so it easily takes charge frm yr hand at lower potential to its ground potential surface.

Send your message to us

Powder Coated Mill Finish Aluminum Sheets for Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords