Baked Enamel Aluminum Sheets for Full Glass Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

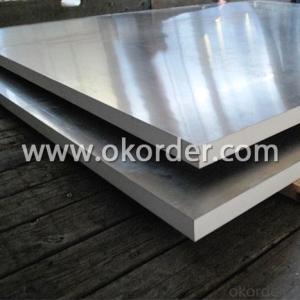

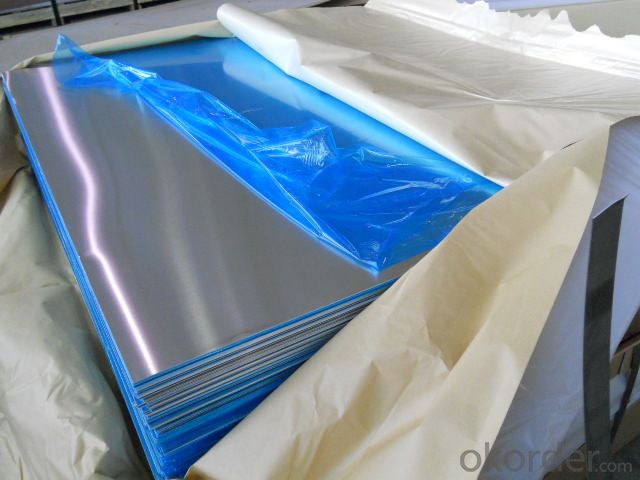

1.Structure of Aluminium Sheets for Full Glass Curtain Wall Aluminium Coils for Full Glass Curtain Wall are one type of non-frame curtain wall than consist of glass panels, point-fixing components on such panels and their supporting structures. . Aluminium Coils for Full Glass Curtain Wall are good at ductility, heat conductivity, anti-corrosion and moisture resistance. They are widely used in roofing, electronics, instruments, lighting decoration, packing, decoration, curtain wall, sandwich panels, boats, etc. 2.Main Features of Aluminium Sheets for Full Glass Curtain Wall •High intensity •Easy to be processed and shaped •Weather resistance •Anti-pollution & environment protection 3. Aluminium Sheets for Full Glass Curtain Wall Images 4.Specification of Aluminium Sheets for Full Glass Curtain Wall Alloy AA1050,AA1060, AA1070, AA1100 Temper: H12, H14, H16, H18, H22, H24, H26, H32,HO, F Thickness: 0.10-500mm Width: 10mm- 2200mm Standard: GB/T3880-2006, ASTM, ISO, EU standard Special Specification is available on customer’s requirement 5.FAQ A.What about inspections to guarantee quality? For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods. With requirement of customers, we also can arrange the third party inspection. B.What about delivery? We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity. C.What is the MOQ? 5 tons for each size. D. Where have you exported? We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: What are the different types of surface treatments available for anodized aluminum sheets?

- There are several types of surface treatments available for anodized aluminum sheets, including polishing, brushing, sandblasting, etching, and coloring. Each treatment option provides a unique aesthetic and functional finish to the aluminum surface.

- Q: Can aluminum sheet be used for electrical grounding applications?

- Yes, aluminum sheet can be used for electrical grounding applications. Aluminum is a good conductor of electricity and is commonly used in electrical grounding systems due to its low resistance and cost-effectiveness.

- Q: What are the environmental benefits of using aluminum sheets?

- There are several environmental benefits of using aluminum sheets. Firstly, aluminum is a highly recyclable material, meaning that it can be reused repeatedly without losing its quality. This reduces the need for mining and extraction of new aluminum, conserving natural resources and minimizing the environmental impact of the production process. Additionally, aluminum has a lower carbon footprint compared to other metals, as it requires less energy to produce. Moreover, aluminum is lightweight, which reduces fuel consumption during transportation, leading to lower greenhouse gas emissions. Overall, using aluminum sheets helps in promoting a more sustainable and eco-friendly approach to manufacturing and construction.

- Q: Are aluminum sheets suitable for food packaging?

- Yes, aluminum sheets are suitable for food packaging. Aluminum is a highly versatile and widely used material in the food industry due to its unique properties. It is lightweight, flexible, and has excellent barrier properties that protect the contents from external factors such as moisture, light, and oxygen. These properties help to maintain the freshness and quality of food products. Additionally, aluminum is resistant to corrosion and does not react with acidic or alkaline substances, ensuring that the taste and quality of the food is preserved. Furthermore, aluminum sheets can be easily shaped into different forms, making them ideal for various types of food packaging such as trays, containers, and foil wraps. Overall, aluminum sheets are a safe and effective choice for food packaging, providing durability, protection, and convenience.

- Q: Can aluminum sheets be formed into seamless tubes or pipes?

- Yes, aluminum sheets can be formed into seamless tubes or pipes. This is typically done through a process called extrusion, where the aluminum sheet is heated and forced through a die to form the desired shape. The extrusion process allows for the creation of seamless tubes or pipes with consistent dimensions and a smooth surface finish. Aluminum is a highly versatile and malleable material, making it suitable for various applications where lightweight and corrosion-resistant tubing is required.

- Q: What is the melting point of 101 aluminum sheets?

- The melting point of 101 aluminum sheets is approximately 660 degrees Celsius or 1220 degrees Fahrenheit.

- Q: Excuse me: what kind of aluminum sheet is the cheapest? Which materials are more expensive?

- Among them, 3003 for aluminum manganese alloy, the lowest price in the 3 series, and then 3004.3104, for aluminum, magnesium, manganese alloy than 3003 price to be slightly higherThird bit, 5 series, i.e. aluminum magnesium alloy, such as 5005.50525083. 5005 of these prices are slightly lowerThen, the ---2 system and --4 system and --7 system of the 6 series are derived

- Q: Calculate the mass in grams of Iodine (I2) that will react completely with 20.4 g of aluminum to form aluminum oxide (AlL3)

- Aluminium oxide? Shouldn't it be Aluminium iodide? 1. Form a balanced equation 3I2 + 4Al - 2Al2I3 2. Number of moles of Al 20.4/(Mr of Al) = 20.4/27 = 0.7555mol 3. Number of moles of I2 0.7555/4 x 3 = 0.5666mol 4. Mass of I2 required = 0.5666 x Mr of I2 = 0.5666 x (127x2) Ans: 143.9164g

- Q: What is the yield strength of aluminum sheets?

- The yield strength of aluminum sheets can vary depending on the specific grade and thickness of the sheet. However, on average, aluminum sheets have a yield strength ranging from 14,000 to 24,000 pounds per square inch (psi).

- Q: How do you prevent discoloration of aluminum sheets?

- To prevent discoloration of aluminum sheets, there are a few steps you can take. Firstly, it is important to clean the aluminum sheets regularly to remove any dirt or debris that could potentially cause discoloration. Use a mild detergent or a specialized aluminum cleaner and a soft cloth or sponge to gently scrub the surface. Avoid using abrasive cleaners or scrubbing pads as they can scratch the surface and make it more prone to discoloration. Secondly, make sure to thoroughly rinse the sheets after cleaning to remove any residue from the cleaning products. Residual chemicals can react with the aluminum and cause discoloration over time. Another preventive measure is to apply a protective coating or sealant on the aluminum sheets. This can help to create a barrier between the metal and the surrounding environment, preventing oxidation and discoloration. There are various types of protective coatings available, such as clear lacquers or anodizing treatments, that can enhance the durability and appearance of the aluminum sheets. Additionally, it is important to store the aluminum sheets in a proper manner to minimize exposure to moisture, humidity, and extreme temperature fluctuations. Moisture can accelerate the oxidation process and lead to discoloration. Store the sheets in a dry and well-ventilated area, away from direct sunlight or sources of heat. Regular maintenance is crucial to prevent discoloration. Inspect the aluminum sheets periodically for any signs of discoloration or damage, and promptly address any issues that arise. By following these preventive measures, you can maintain the aesthetic appeal and longevity of aluminum sheets.

Send your message to us

Baked Enamel Aluminum Sheets for Full Glass Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords