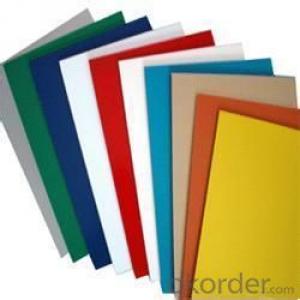

Aluminum Sheets in South Dakota - Aluminium Plain Sheet for Construction and Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

3003-H14 Aluminum Sheet - (ASTM B209) Excellent weldability, formability, with good corrosion resistance make 3003 Aluminum Plate a popular and economical choice. 3003 Aluminum Plate has a smooth, shiny finish and is popular for many cosmetic and industrial applications, including: decorative trim, fuel tanks, food & chemical handling, trailer siding & roofing, etc.

Non-magnetic, Brinell = 40, Tensile = 22,000, Yield = 21,000 (+/-)

5052-H32 Aluminum Sheet - (ASTM B20) Superior corrosion resistance, good weldability, with excellent formability, makes 5052Aluminum Plate a common choice for chemical, marine or saltwater applications. 5052 Aluminum Plate applications include: tanks, drums, marine hardware, boat hulls, etc.

Non-magnetic, Brinell = 60, Tensile = 33,000, Yield = 28,000 (+/-)

6061-T651 Aluminum Sheet - (ASTM B209, QQ-A 250/11) Offers a combination of increased strength, corrosion resistance, and machinability making it the most widely used aluminum grade. 6061 Aluminum Plate is heat treatable, resists cracking due to stress, is easy to weld and machine, but limited on formability. 6061 Aluminum Plate is ideal for structural framing, base plates, gussetts, motorcycle & automotive parts, etc.

Non-magnetic, Brinell = 95, Tensile = 45,000, Yield = 40,000 (+/-)

- Q: why is it gd and what are common aluminium compounds??? thx

- It's quite expensive to make aluminum, whereas it's quite cheap to melt it down and reuse it.

- Q: What specific criteria or standards must be met when utilizing recycled aluminum in construction?

- <p>Recycled aluminum products used in construction projects must meet specific requirements to ensure safety, durability, and compliance with building codes. These include adherence to ASTM standards for recycled aluminum alloys, such as ASTM B601 for ingots and ASTM B209 for rolled or cold finished products. The recycled aluminum must also have consistent mechanical properties and corrosion resistance comparable to virgin aluminum. Additionally, the products should be free from contaminants that could compromise structural integrity. It's crucial to verify the source and processing methods of recycled aluminum to ensure it meets these standards before use in construction.</p>

- Q: Can aluminum sheets be an alternative to wood in certain applications?

- Certainly, aluminum sheets can serve as a viable substitute for wood in specific applications. Aluminum boasts numerous advantages over wood, rendering it a favored choice across various industries. Primarily, aluminum exhibits exceptional durability and longevity due to its resistance to corrosion, rot, and pests. Consequently, it proves ideal for outdoor usage or areas with high moisture levels. Moreover, aluminum sheets are lightweight, facilitating easier handling and transportation in comparison to wood. Additionally, they possess a commendable strength-to-weight ratio, enabling them to withstand heavy loads while maintaining their structural integrity. Moreover, aluminum stands as a sustainable material, capable of indefinite recycling without compromising its properties. Conversely, wood necessitates the felling of trees, thereby carrying environmental implications. Aluminum sheets also offer a high degree of design flexibility, readily assuming complex structures through shaping, bending, and forming. This adaptability allows for innovative and creative applications. Furthermore, aluminum exhibits excellent thermal and electrical conductivity, rendering it suitable for scenarios where heat dissipation or electrical conductivity plays a crucial role. Nonetheless, it is crucial to acknowledge that wood retains its unique characteristics and benefits in certain applications. Wood imparts a warm and natural aesthetic that aluminum fails to replicate, making it a preferred choice in interior design or furniture manufacturing. Additionally, wood qualifies as a renewable resource and exhibits excellent insulation properties, proving advantageous in construction or insulation applications. Consequently, while aluminum sheets can serve as a fantastic substitute for wood in numerous instances, the ultimate choice hinges upon the specific requirements and desired outcomes of the application at hand.

- Q: This question asks for methods to protect aluminum sheets from damage during transportation and storage.

- <p>To prevent damage to aluminum sheets during transportation or storage, follow these guidelines: 1) Use protective packaging such as bubble wrap or padded covers to prevent scratches and dents. 2) Store aluminum sheets in a dry, cool place away from moisture and direct sunlight to avoid corrosion. 3) Stack sheets with soft padding between them to prevent surface damage. 4) Securely strap or brace the sheets during transport to prevent movement and potential damage. 5) Handle aluminum sheets with clean, dry hands or use gloves to avoid leaving fingerprints or oils that can cause corrosion. 6) Ensure that transportation vehicles are clean and dry to prevent any contaminants from coming into contact with the aluminum. By adhering to these practices, you can minimize the risk of damage to aluminum sheets.</p>

- Q: Are aluminum sheets easy to work with?

- Aluminum sheets, in general, prove to be easily manageable. Being a light and flexible metal, aluminum allows for easier cutting, shaping, and manipulation compared to its counterparts. It boasts the ability to be effortlessly bent, formed, and welded, granting access to a variety of fabrication methods. Furthermore, aluminum sheets exhibit excellent resistance to corrosion, which enhances their user-friendliness. Whether the goal is constructing lightweight structures, fabricating components, or crafting intricate designs, aluminum sheets offer versatility and convenience across numerous applications.

- Q: Can aluminum sheets be used for cladding?

- Yes, aluminum sheets can definitely be used for cladding. Aluminum is a popular choice for cladding due to its many beneficial properties. It is lightweight, durable, corrosion-resistant, and has excellent thermal and acoustic insulation properties. It is also highly malleable, allowing for various design possibilities. Aluminum cladding is commonly used in both residential and commercial buildings to provide protection, enhance aesthetics, and improve energy efficiency.

- Q: Are the aluminum sheets suitable for manufacturing sporting equipment?

- Yes, aluminum sheets are suitable for manufacturing sporting equipment. Aluminum is a lightweight and durable material that can be easily molded and shaped into various sporting equipment such as tennis rackets, baseball bats, and golf clubs. It offers excellent strength-to-weight ratio, corrosion resistance, and allows for better performance and maneuverability in sports activities.

- Q: How do you prevent oxidation of aluminum sheets?

- One way to prevent oxidation of aluminum sheets is by applying a protective coating or paint to the surface. This barrier creates a physical barrier between the aluminum and oxygen, preventing the oxidation process from occurring. Additionally, storing the aluminum sheets in a dry and controlled environment, away from moisture and humidity, can help minimize the chances of oxidation.

- Q: Can the aluminum sheets be used in the construction industry?

- Yes, aluminum sheets can definitely be used in the construction industry. Aluminum is a versatile and lightweight material that offers several advantages for construction applications. It is corrosion-resistant, which makes it ideal for outdoor structures and buildings. Aluminum sheets are commonly used for roofing, siding, window frames, doors, and other architectural elements. Additionally, aluminum's high strength-to-weight ratio allows for the construction of durable and efficient structures. Its malleability also makes it easy to fabricate and shape into various forms, allowing for creative and innovative designs in construction projects. Overall, aluminum sheets are a popular choice in the construction industry due to their durability, versatility, and aesthetic appeal.

- Q: How do aluminum sheets perform in terms of weather resistance?

- Aluminum sheets are known for their excellent weather resistance properties. Due to their inherent corrosion resistance, aluminum sheets can withstand exposure to various weather conditions without deteriorating or rusting, making them highly suitable for outdoor applications. The protective oxide layer that naturally forms on the surface of aluminum provides a barrier against moisture, preventing the metal from reacting with oxygen and thus reducing the risk of corrosion. Additionally, aluminum sheets have high resistance to UV radiation, making them resistant to fading or discoloration caused by prolonged exposure to the sun. Overall, aluminum sheets offer exceptional performance in terms of weather resistance, making them a reliable choice for a wide range of outdoor applications, including roofing, siding, and outdoor signage.

Send your message to us

Aluminum Sheets in South Dakota - Aluminium Plain Sheet for Construction and Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords