Aluminum Siding 4x8 Sheets - Aluminium Sheet with Better Price in Warehouse with Stocks

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t

- Supply Capability:

- 2500 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5000 series, 6000series,7000 series, 8000 series,etc. The detailed grade are as follows: 1010, 1050,1060,1100, 2024, 3003, 3005, 3105, etc.

The temper is include H14, H22, H24, H44,H114,etc.

2. Main features of the product

a.Competitive price

c. Shortest service.

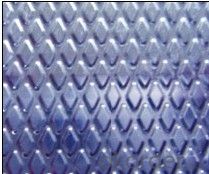

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1500*3000mm,etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the wh range?

---It is from 20 to 6000mm, etc.

What is the Mr your products yet?

---Normally it is around 4 tons/each size.

How many tons du export in one year

Fiji,Indonesia,Canada, Vietnam,Turkey,etc.

What is your basic products?

---Normally they are aluminum sheet,big and small-5-bar aluminium checkered sheet, big-5-bar aluminum sheet and aluminum checkered sheet and aluminum mirror finishedc. checkered aluminium plate, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: What is the weight of a standard aluminum sheet?

- The weight of a standard aluminum sheet can vary depending on its dimensions and thickness. However, on average, aluminum sheets typically weigh around 2.7 grams per cubic centimeter. To determine the weight of a specific aluminum sheet, you would need to know the dimensions (length, width, and thickness) and multiply them to obtain the sheet's volume. Then, you can multiply the volume by the density of aluminum (2.7 g/cm³) to calculate the weight in grams.

- Q: Should I purchase a camper made out of aluminum/wood or a fiberglass?I'm looking to purchase a small camper, approx 18', to tow on the back of my SUV. It's a 2011 Wildwood camper. However, I hear campers made out of aluminum and wood aren't very good because the wood can ruin in time and the aluminum can rust, etc. I hear fiberglass campers are better? Anyone have any knowledge or experience with this? Also, any thoughts or advice with brands/models? And about the Wildwood? Thanks in advance.

- Aluminum is lighter so it offers economies over the life of the trailer. The Airstream has been built almost as long as I've been around. It is true that the wood does rot And some care is needed to stop the occasional leak. Fiberglass is heaver and has it's own maintenance issues. I've no experience with the Wildwood. What I do know is that motor homes are dirt cheap right now. You might think about taking advantage of the economy and pick-up a motor home at a bargain.

- Q: What precautions should be taken to ensure safety while installing aluminum sheets?

- <p>When installing aluminum sheets, safety measures include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and hard hats. Ensure the work area is clear of debris and any tripping hazards. Use ladders and scaffolding that are in good condition and set up correctly. Always have a spotter when lifting heavy sheets and use proper lifting techniques to avoid back injuries. Keep hands and feet away from edges and corners to prevent cuts. Ensure all tools are in good working order and use them correctly. Follow all manufacturer's guidelines for installation and adhere to local safety regulations.</p>

- Q: What type of aluminium sheet is a food grade?

- Pure aluminum, alloy aluminum can be. However, the majority of pure aluminum. Used by customers.

- Q: How thick are aluminum sheets commonly available?

- Aluminum sheets commonly come in various thicknesses, depending on the intended use and application. The most commonly available aluminum sheet thicknesses range from 0.025 inches (0.63 mm) to 0.125 inches (3.18 mm). However, thinner and thicker aluminum sheets are also available, with some going as thin as 0.016 inches (0.4 mm) and others as thick as 0.25 inches (6.35 mm) or more. The specific thickness required will depend on the specific project or industry application.

- Q: Are aluminum sheets suitable for automotive body panels?

- Yes, aluminum sheets are suitable for automotive body panels for several reasons. Firstly, aluminum is a lightweight material, which helps improve fuel efficiency and overall vehicle performance. This can result in better acceleration, handling, and braking. Additionally, the use of aluminum body panels can contribute to reducing the overall weight of the vehicle, which is particularly important for electric vehicles, as it can extend their range. Secondly, aluminum has excellent corrosion resistance properties. It naturally forms a protective oxide layer on its surface, which helps prevent rusting and deterioration caused by exposure to various weather conditions. This makes aluminum sheets highly durable and long-lasting, ensuring that automotive body panels maintain their structural integrity over time. Furthermore, aluminum is highly malleable and can be easily formed into complex shapes using various manufacturing techniques such as stamping, extrusion, and hydroforming. This allows for greater design flexibility, enabling automakers to create vehicles with sleek and aerodynamic body styles. Additionally, aluminum can be easily joined through welding or adhesive bonding, making it easier to assemble and repair automotive body panels. Moreover, aluminum is a sustainable material as it is highly recyclable. Recycling aluminum requires significantly less energy compared to primary production, resulting in reduced greenhouse gas emissions. This aligns with the growing emphasis on sustainability and environmental consciousness in the automotive industry. Overall, the use of aluminum sheets in automotive body panels offers numerous advantages such as improved fuel efficiency, corrosion resistance, design flexibility, and sustainability. These factors make aluminum a suitable and increasingly popular choice for automakers aiming to enhance the performance, durability, and environmental friendliness of their vehicles.

- Q: which kind of aluminum sheet could be bended after being etched?

- general etching materials include stainless steel and copper.

- Q: What are the weight-saving benefits of using aluminum sheets in different applications?

- Using aluminum sheets in various applications offers several benefits for weight-saving. Firstly, aluminum is a lightweight metal with a density much lower than commonly used materials like steel. This means that by replacing steel sheets with aluminum sheets, significant weight reduction can be achieved in different applications. The reduced weight of aluminum sheets is especially advantageous in transportation industries. For instance, in the automotive sector, using aluminum sheets for body panels, chassis components, and other structural parts can significantly lighten the overall weight of vehicles. This weight reduction leads to improved fuel efficiency as it requires less energy to move the lighter vehicle. Additionally, lighter vehicles generally exhibit better acceleration, handling, and braking performance. In the aerospace industry, the weight-saving benefits of aluminum sheets are even more crucial. Every additional kilogram of weight on an aircraft can increase fuel consumption and operating costs. By utilizing lightweight aluminum sheets in the construction of aircraft structures such as wings, fuselages, and engine components, the overall weight of the aircraft can be reduced, resulting in improved fuel efficiency and extended flight range. The construction sector also highly values the weight-saving benefits of aluminum sheets. Due to their lightweight nature, aluminum sheets are often used in building and infrastructure construction. This characteristic not only makes installation easier but also reduces the load on the building's foundation. Moreover, using aluminum sheets in construction can lead to cost savings as lighter materials require less support structure and can be transported more efficiently. Furthermore, the weight-saving benefits of aluminum sheets extend to various other applications such as packaging, electronics, and consumer goods. In packaging, aluminum sheets are commonly used for lightweight and flexible packaging materials, reducing shipping costs and environmental impact. In electronics, aluminum sheets are used in devices like laptops and smartphones, where weight reduction is desirable for portability. Lastly, in consumer goods, aluminum sheets are utilized for producing lightweight and durable products such as furniture, cookware, and sports equipment. In conclusion, the weight-saving benefits of using aluminum sheets in different applications are significant. Aluminum's lightweight nature allows for weight reduction in transportation industries, improved fuel efficiency, better performance, and extended flight range in aerospace applications, cost savings, and easier installation in construction, as well as various advantages in packaging, electronics, and consumer goods. Overall, aluminum sheets provide a versatile and efficient solution for achieving weight reduction and enhancing performance in diverse industries.

- Q: Are aluminum sheets suitable for decorative screens?

- Yes, aluminum sheets are suitable for decorative screens. They are lightweight, durable, and can be easily customized into various shapes and designs. Additionally, aluminum's corrosion resistance makes it suitable for both indoor and outdoor applications, making it a popular choice for decorative screens.

Send your message to us

Aluminum Siding 4x8 Sheets - Aluminium Sheet with Better Price in Warehouse with Stocks

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t

- Supply Capability:

- 2500 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords