4 8 Aluminum Sheets - Aluminium Drawn Slab with Best Stock Price in Warehouse

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

aluminum sheet and cold rolled aluminum mirror finish sheet are all widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5000 series, 6000 series, 7000 series, 8000 series, etc.

The detailed alloy number and temper are as follows: 1010, 1050,1060,1100, 2024, 3003, 3005, 3105,075, 8011,etc.

The temper is include H14, H22, H24, H44,H112, F, H114,etc.

2. Main features of the product

a. Competitive price

c. Shortest service.

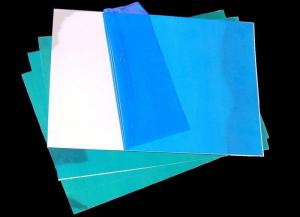

3. Image.

4. Product detailed sizes:

1000mm*2000mm,1000mm*1000mm,500mm*500mm,1220mm*2440mm,1219*2438mm,etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 400mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 11 tons/each size.

How many tons did you export in one year

USA, England, sri lanka, bangladesh, etc

What is your mainly products?

---Normally they are cold drawn checkered sheet and hot drawn checkered sheet cold rolled and hot rolled and cold drawn aluminum sheet,mirror finish aluminium sheet,aluminium checkered sheet,aluminum casting coil, etc.

- Q: Can aluminum sheets be used in aerospace industries?

- Yes, aluminum sheets are commonly used in aerospace industries. Aluminum is a lightweight and corrosion-resistant material that possesses excellent strength-to-weight ratio, making it ideal for various aerospace applications. It is used in the construction of aircraft structures, such as wings, fuselage, and landing gear, due to its ability to withstand high stress and pressure. Additionally, aluminum sheets are easily formable and can be fabricated into complex shapes, contributing to the design flexibility required in the aerospace industry. However, it is important to note that aluminum alloys are typically used in aerospace applications rather than pure aluminum, as they offer enhanced mechanical properties and improved performance.

- Q: How do you prevent distortion of aluminum sheets during welding?

- To prevent distortion during the welding of aluminum sheets, there are several important steps that can be taken: 1. It is crucial to properly prepare the joint by cleaning and beveling the edges of the aluminum sheets. This will ensure a better fit-up and reduce the likelihood of distortion. 2. The use of appropriate fixtures and clamps to hold the aluminum sheets in place during welding can help distribute the heat evenly and prevent movement or buckling. This will minimize the risk of distortion caused by thermal expansion. 3. Tack welding can be done at regular intervals along the joint before performing a full weld. This temporarily secures the sheets and allows for controlled cooling, reducing distortion. 4. Following a proper welding sequence is also beneficial. Starting from the center and gradually moving towards the edges, alternating between sides, helps balance the heat input and allows for cooling between welds, minimizing distortion. 5. Preheating the material before welding can help reduce the temperature gradient and minimize distortion for thicker aluminum sheets. Post-weld heat treatment can also be applied to relieve residual stresses and promote dimensional stability. 6. Employing appropriate welding techniques, such as lowering the heat input and using a slower travel speed, can help minimize distortion. Using a smaller weld bead size and avoiding excessive weaving also control the heat input and reduce distortion. 7. It is crucial to ensure that the welding parameters, such as voltage, current, and wire feed speed, are correctly set and maintained. Using the appropriate parameters for the specific aluminum alloy being welded will result in a more controlled heat input, reducing distortion. By implementing these preventive measures, the risk of distortion during aluminum sheet welding can be significantly reduced, leading to improved weld quality and dimensional stability.

- Q: Can aluminum sheets be coated with protective films?

- Indeed, it is possible to coat aluminum sheets with protective films. Typically, these films are composed of materials like polyethylene or polypropylene and serve the purpose of creating a defense against scratches, abrasions, and additional types of harm. By applying the protective film onto the aluminum sheet's surface, a safeguarding layer is formed, shielding it from any potential damage that may occur during handling, transportation, or processing. Through this coating process, the aluminum sheet's integrity and appearance are preserved, guaranteeing that it remains in impeccable condition until it is prepared for utilization.

- Q: Are 101 aluminum sheets suitable for outdoor signage?

- Yes, 101 aluminum sheets are suitable for outdoor signage. Aluminum is known for its durability and resistance to weathering, making it an ideal material for outdoor applications. The 101 aluminum alloy is specifically designed for high-strength and corrosion resistance, making it even more suitable for outdoor signage. It can withstand harsh weather conditions, including rain, snow, UV exposure, and temperature variations, without corroding or deteriorating. Additionally, aluminum sheets are lightweight, making them easy to install and transport. Overall, 101 aluminum sheets provide a reliable and long-lasting solution for outdoor signage.

- Q: 1. Esrp for aluminum is -1.66V. Why is Al not reactive when dipped in cold water?2. Explain why the reaction between water and Al becomes more reactive when Al has been treated first with Mercury chloride.3. Aluminum hydroxide dissolve in both acid and base. What do you call this type of behavior?4. Describe the function of aluminum hydroxide in the testile industry.5. Aluminum sol. which contains [Al(H2O)6]3+ ions have the tendency to hydrolyze. Why? Recommend a method to prevent hydrolysis of aluminum ions.6. In the preparation of alum, sulphuric acid is added to the aluminum hydroxide sol. Why?

- Al is not reactive because it is so reactive - it gets coated with oxide immediately on exposure, the oxide layer is strong and quite inert except to strong acids.

- Q: Also what are some intersting facts about Aluminum? (the element) thanks 2 any 1 who answers =)

- Corrosion resistance due to passivation and low density.

- Q: What are the maximum dimensions of aluminum sheets?

- The maximum dimensions of aluminum sheets can vary depending on the manufacturing capabilities of different suppliers. However, in general, aluminum sheets are available in a wide range of sizes to meet various application requirements. Commonly, the maximum width of aluminum sheets can be up to 72 inches (6 feet), while the maximum length can reach around 240 inches (20 feet). These dimensions can provide ample material for a wide range of projects, including construction, manufacturing, and industrial applications. It is important to note that specific suppliers may have their own limitations, so it is advisable to consult with them directly to determine the maximum dimensions available for aluminum sheets.

- Q: What specific conditions are necessary for the storage and transportation of aluminum sheets to ensure their quality and safety?

- <p>Yes, there are special requirements for storing and transporting aluminum sheets. Aluminum sheets should be stored in a dry, cool place to prevent moisture and temperature extremes which can cause warping or corrosion. They should be stacked flat and evenly to avoid bending or denting. When transporting, aluminum sheets should be secured to prevent shifting during transit, which can lead to damage. Protective coverings may be used to shield the sheets from dirt, scratches, or other potential hazards. It's also crucial to handle the sheets carefully to avoid bending or denting, which can occur if they are not properly supported during transport.</p>

- Q: Thickness of Aluminum Foil A rectangular sheet ofaluminum foil is 50 centimeters long and 20 centimeterswide, and weighs 5.4 grams. Find the thicknessof the aluminum foil in centimeters

- density Aluminum 2700 kg/m? Volume = 0.5 x 0.2 x d = 0.1d m? where d is thickness 5.4 g = 0.0054 kg 0.0054 kg / 2700 kg/m? = 2.0e-6 m? 2.0e-6 m? = 0.1d m? d = 2.0 e-5 m or 20 ?m or 0.02 mm or 0.002 cm .

- Q: How do aluminum sheets compare to steel sheets in terms of strength?

- Strength differs between aluminum sheets and steel sheets. Steel is generally stronger than aluminum due to its higher tensile strength, allowing it to withstand greater forces without breaking or deforming. Steel sheets find common use in construction, automotive manufacturing, and aerospace, where high strength and durability are necessary. Conversely, aluminum sheets strike a good balance between strength and weight. Although not as strong as steel, aluminum is significantly lighter, making it advantageous in applications prioritizing weight reduction, such as aircraft and vehicle manufacturing. Additionally, aluminum sheets exhibit excellent corrosion resistance, making them suitable for outdoor or marine environments. Ultimately, the choice between aluminum and steel sheets hinges on the specific requirements of the application, considering factors like strength, weight, durability, and corrosion resistance.

Send your message to us

4 8 Aluminum Sheets - Aluminium Drawn Slab with Best Stock Price in Warehouse

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords