Black Anodized Aluminum Sheets 4x8 - Aluminium Sheet with Best Discount Price Warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

Cold rolled aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5052,5754,7075,3105,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

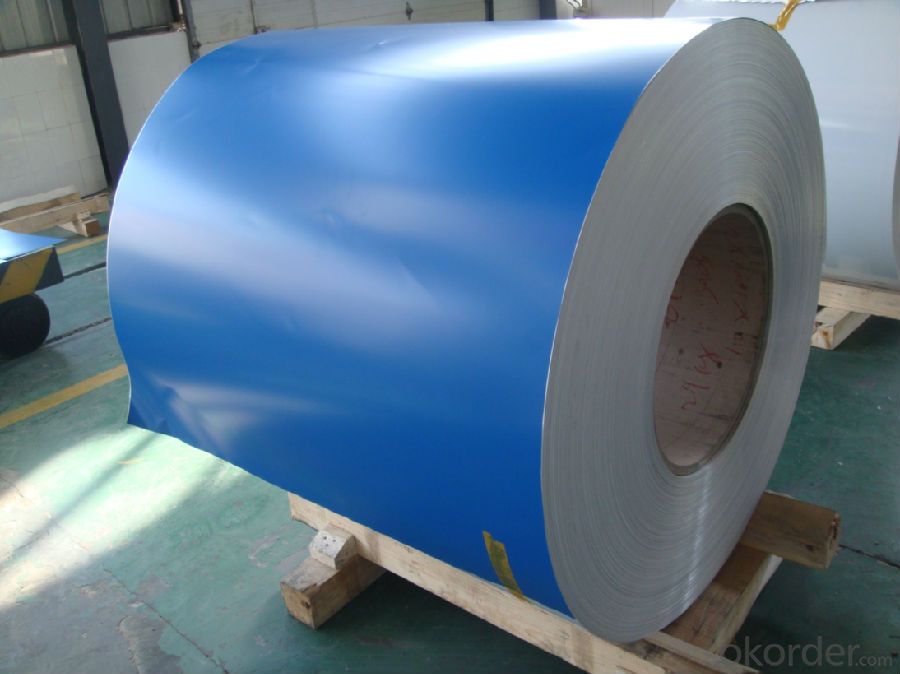

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1220mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from Japan,ENGL,

AND, FIJI, SRI LANKA, ETCENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: What are the safety precautions when working with aluminum sheets?

- When working with aluminum sheets, it is important to take certain safety precautions to ensure your well-being. Here are some key safety measures to follow: 1. Personal Protective Equipment (PPE): Always wear appropriate PPE, such as safety goggles, gloves, and a face mask, to protect yourself from potential hazards. Aluminum sheets may produce sharp edges, metal filings, or dust particles that can cause injury if they come into contact with your eyes, skin, or respiratory system. 2. Ventilation: Ensure that the work area is well-ventilated to minimize the buildup of aluminum dust or fumes. Proper ventilation helps in preventing the inhalation of harmful airborne particles, especially when cutting or shaping aluminum sheets. 3. Handling and storage: Handle aluminum sheets with care to avoid injuries. They can have sharp edges, so it is essential to wear gloves while handling them. Additionally, store the sheets in a secure and organized manner to prevent accidents like tripping or falling. 4. Cutting and shaping: When cutting or shaping aluminum sheets, use appropriate tools designed for this purpose. Avoid using tools that are not suited for aluminum, as they may cause damage or create unsafe conditions. Ensure that the cutting area is clear of clutter, and be mindful of your body position to avoid accidents. 5. Fire safety: Aluminum is a highly flammable material, so it is crucial to be cautious of fire hazards. Keep flammable materials away from the work area, and avoid using open flames or sparks in the vicinity. In case of a fire, have a fire extinguisher readily available and know how to use it effectively. 6. Training and knowledge: It is important to have proper training and knowledge about working with aluminum sheets. Understanding the properties of aluminum, the appropriate techniques, and safety precautions can help prevent accidents and injuries. 7. Regular maintenance: Keep your tools and equipment in good working condition. Regularly inspect them for any damage or wear and tear, and replace or repair as necessary. Faulty or poorly maintained tools can increase the risk of accidents when working with aluminum sheets. By following these safety precautions, you can minimize the potential risks and ensure a safe working environment when handling aluminum sheets.

- Q: What are the different methods of joining aluminum sheets?

- There are several methods of joining aluminum sheets, including welding, adhesive bonding, mechanical fastening (such as riveting or screwing), and clinching. Each method has its own advantages and considerations, depending on the specific application and desired outcome.

- Q: This question asks for a comparison between aluminum sheets and other types of sheet metal regarding their strength and durability.

- <p>Aluminum sheets are known for their high strength-to-weight ratio, making them lighter than many other sheet metals such as steel. They offer excellent corrosion resistance, which contributes to their durability. However, in terms of sheer strength, aluminum is not as strong as steel or titanium. Steel is stronger but also heavier, and while titanium is very strong and durable, it is also more expensive and less commonly used in construction and manufacturing. Aluminum's malleability allows it to be easily shaped and formed, and it is also non-magnetic and has good thermal conductivity. Overall, aluminum is a popular choice for applications requiring a balance between strength, weight, and resistance to corrosion.</p>

- Q: Would you please tell me what putty to use on the aluminium board, what kind of putty, and the painting process?

- Applied atomic ash.Consider adding an interface agent, that is, applying an interfacial agent on the aluminum plate, and then applying a topcoat on the interface agent after drying.

- Q: What is the typical shear strength of aluminum sheets?

- The shear strength of aluminum sheets can vary depending on several factors, including the alloy, temper, thickness, and manufacturing process. Typically, common aluminum alloys have a shear strength ranging from 207 to 310 megapascals (MPa) or 30,000 to 45,000 pounds per square inch (psi). It is crucial to understand that these values serve as general guidelines, and specific applications and conditions may result in variations. When dealing with critical applications, it is advisable to refer to the material specifications or consult professionals to accurately determine the shear strength requirements for the specific aluminum sheet in use.

- Q: What are the advantages of using aluminum sheets in the transportation industry?

- There are several advantages of using aluminum sheets in the transportation industry. Firstly, aluminum is a lightweight material, making it ideal for use in vehicles as it helps reduce fuel consumption and increase overall efficiency. This is particularly important for industries such as aviation and automotive, where weight reduction is a key factor in improving performance. Secondly, aluminum has excellent corrosion resistance properties. This is crucial in the transportation industry, where vehicles are exposed to various environmental conditions such as rain, snow, and road salt. Using aluminum sheets helps to extend the lifespan of vehicles and reduces maintenance costs associated with corrosion-related issues. Additionally, aluminum is highly recyclable, making it a more sustainable choice compared to other materials. The transportation industry is increasingly focusing on sustainability, and the use of aluminum sheets aligns with these goals. Recycling aluminum requires significantly less energy compared to producing it from raw materials, leading to reduced carbon emissions and energy consumption. Moreover, aluminum offers excellent formability and versatility. It can be easily molded into various shapes and sizes, allowing manufacturers to design lightweight yet strong structures. This flexibility in design enables the production of more aerodynamic vehicles, leading to improved fuel efficiency. Lastly, aluminum sheets have high strength-to-weight ratio, meaning they can provide the required strength while still being lightweight. This property makes aluminum an ideal material for applications that require strength and durability, such as vehicle bodies, chassis, and structural components. Overall, the advantages of using aluminum sheets in the transportation industry include weight reduction, corrosion resistance, sustainability, formability, versatility, and high strength-to-weight ratio. These benefits contribute to improved performance, fuel efficiency, and durability of vehicles, making aluminum an excellent choice for various transportation applications.

- Q: I'm gonna drop the dime and get a bass boat. other than weight why is a fiberglass better than aluminum?I'm looking at the difference between the top of the line BassTracker and the bottom of the line Nitro. I only want about a 90 -115 hp and I'm gonna buy a couple years old to save some money.. so what are the pros - cons?

- Bass Tracker Aluminum Boats

- Q: Can the aluminum sheets be used for manufacturing chemical reaction vessels?

- Aluminum sheets are indeed capable of being utilized in the production of chemical reaction vessels. The utilization of aluminum, a versatile substance, presents numerous benefits for this particular purpose. Its lightweight nature, durability, and exceptional resistance to corrosion render it suitable for the containment and interaction of various chemicals. Furthermore, the malleability of aluminum enables it to be easily molded and shaped into the desired design for the vessel, granting flexibility in the manufacturing process. Nevertheless, it is crucial to acknowledge that aluminum may not be suitable for all chemical reactions, particularly those involving highly corrosive or reactive substances. In such instances, alternative materials capable of withstanding the specific conditions of the reaction may prove to be more appropriate.

- Q: Over 5 billion aluminum cans are recycled each year. If laid end to end, these cans would form a line reaching from?

- IDK, but this may give you some idea of 1 billion. 1 Billion seconds ago.. It was 1959 1 Billion minutes ago... Christ was alive.

- Q: Are aluminum sheets suitable for decorative paneling?

- Yes, aluminum sheets are suitable for decorative paneling. Aluminum is a versatile material that offers a range of benefits for decorative applications. Firstly, aluminum sheets are lightweight, making them easy to handle and install. This makes them a practical choice for both interior and exterior paneling. In addition to being lightweight, aluminum sheets are also durable and corrosion-resistant. They can withstand various weather conditions, including humidity and UV exposure, without losing their appearance or structural integrity. This durability ensures that the decorative paneling will maintain its aesthetic appeal over time, even in high-traffic areas. Furthermore, aluminum sheets provide a sleek and modern look to any space. They can be easily customized through various finishes, such as brushed, polished, or anodized, allowing for endless design possibilities. The reflective properties of aluminum can also enhance the overall appearance of a room by creating an illusion of more space and light. Moreover, aluminum is a sustainable material, as it is fully recyclable without compromising its quality. This makes it an environmentally friendly choice for decorative paneling, aligning with the growing trend towards sustainable design. Overall, aluminum sheets are an excellent option for decorative paneling due to their lightweight nature, durability, versatility in design options, and sustainable properties. Whether for residential or commercial purposes, aluminum paneling can add a modern and visually appealing touch to any space.

Send your message to us

Black Anodized Aluminum Sheets 4x8 - Aluminium Sheet with Best Discount Price Warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords