Mill Finished Aluminum Sheets 48 X 96 for Building Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finished Aluminium Sheet for Building Curtain Wall

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC AA8011 AA8006 AA8079 ETC |

TEMPER | H14,H16,H18,H22,H24,H26,H32,O/F |

THICKNESS | ≥0.2MM |

WIDTH | 30mm-2100mm |

COIL WGT | 2Mt - 3Mt |

COIL ID | φ508mm,φ610mm |

SURFACE | PE Protecting film |

STANDARD | GB/T 3880-2006 |

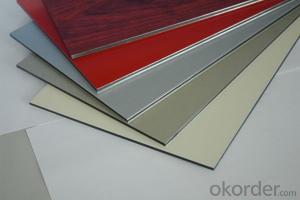

2. Application of Mill Finished Aluminium Sheet for Building Curtain Wall

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finished Aluminium Sheet for Building Curtain Wall

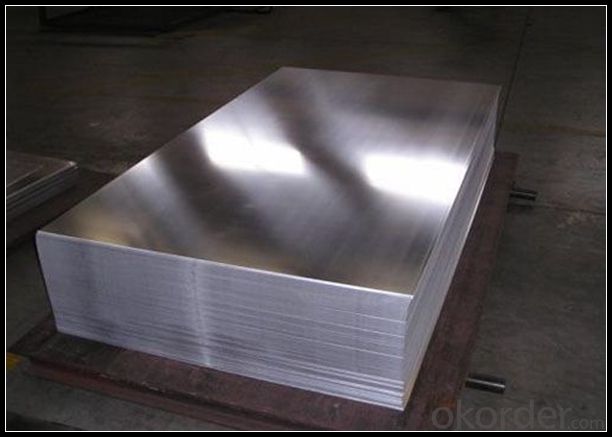

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

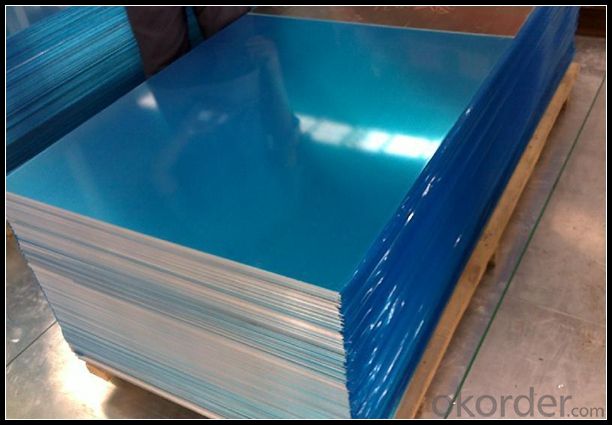

5. Image of Mill Finished Aluminium Sheet for Building Curtain Wall

6. Package and shipping of Mill Finished Aluminium Sheet for Building Curtain Wall

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: AND WAT R THE THECNOLOGICAL ANDCOSTS AND BENEFITESOF USING ALUMINUM? what health -related and environment-related issues gave surface as aresult of its widespread use in society?

- airplanes are made from aluminum. certain beverages are also. aluminum is cheaper and lighter. the biggest problem is the amount of electricity that it takes to make aluminum

- Q: Why must the aluminum oxide be electrolyzed in a molten cryolite solution?

- To electrolyse aluminium oxide, it has to be molten. However, the melting point of Al2O3 is extremely high ( 1000°C), and that would make the electrolysis very inefficient. However, Al2O3 dissolves in cryolite at much lower temperatures (lower than 900°C), which makes it a much more viable process.

- Q: This question asks about the expected duration or service life of aluminum siding or cladding used in construction.

- <p>The lifespan of aluminum siding or cladding typically ranges from 20 to 50 years, depending on the quality of the material, installation, and environmental conditions. High-quality aluminum siding, when properly maintained and installed, can last up to 50 years. It is resistant to rust and decay, making it a durable choice for exterior cladding. However, factors such as extreme weather conditions, poor installation, and lack of maintenance can reduce its lifespan.</p>

- Q: is aluminum foil spacer poisonous after heating?

- many baked food will use aluminum foil.

- Q: What are the different methods of surface treatment for adhesive bonding of aluminum sheet?

- There are several different methods of surface treatment for adhesive bonding of aluminum sheet. These methods can help improve the bond strength and durability of the adhesive joint. Some common methods include: 1. Mechanical Surface Treatment: This method involves roughening the aluminum surface using techniques such as sandblasting, abrasion, or wire brushing. The roughened surface creates a better mechanical interlock between the adhesive and the aluminum, increasing the bond strength. 2. Chemical Surface Treatment: Chemical treatments can be used to remove contaminants, oxidation, or corrosion from the aluminum surface. Common chemical treatments include acid etching, chromate conversion coating, or anodizing. These treatments improve the surface cleanliness and promote adhesion by creating a chemically reactive surface for the adhesive. 3. Plasma Treatment: Plasma treatment involves exposing the aluminum surface to a low-temperature plasma discharge. This process modifies the surface energy and removes contaminants, thereby enhancing the wettability and adhesion of the adhesive. 4. Primer Coating: Applying a primer coat on the aluminum surface can improve adhesion by promoting chemical bonding between the adhesive and the substrate. Primers are typically designed to promote adhesion to specific substrates and can enhance the bond strength and durability of the adhesive joint. 5. Surface Activation: Surface activation techniques, such as flame treatment or corona treatment, can be used to increase the surface energy of the aluminum sheet. These methods create free radicals on the surface, which improve the bonding characteristics of the adhesive. It's important to note that the selection of the surface treatment method depends on various factors like the specific adhesive used, the desired bond strength, the application requirements, and the condition of the aluminum surface. Therefore, it is recommended to consult adhesive manufacturers or experts to determine the most suitable surface treatment method for a specific adhesive bonding application.

- Q: What is the typical wear resistance of aluminum sheets?

- The typical wear resistance of aluminum sheets can vary depending on factors such as alloy composition, tempering, and surface treatment. However, in general, aluminum sheets have relatively low wear resistance compared to materials like steel or titanium. They are more prone to scratching, abrasion, and surface damage. To enhance wear resistance, additional coatings or treatments can be applied to aluminum sheets.

- Q: On candle when candle flame is about 1.000 degrees celsius and melting point of aluminum is 660 degrees celsius.

- if a candle is 1000 degrees u can melt aluminum with it, it wont happen straight away, you have to give the metal a long time to heat up as it conducts heat it will take ages, you will prob let go or get bored before the metal has chance to heat up

- Q: How many square meters does the aluminum plate engrave?

- The price of aluminum sheet is calculated according to the price of aluminum ingot + processing fee (aluminum plate state), and the specific price is also different according to the size and size of aluminum sheet. If you have any questions, please ask, thank you.

- Q: How do aluminum sheets perform in terms of thermal conductivity?

- Aluminum sheets exhibit high thermal conductivity, making them efficient in transferring heat and facilitating heat dissipation.

- Q: What are the different types of coatings applied to aluminum sheet?

- There are several types of coatings that can be applied to aluminum sheets. Some common ones include anodizing, powder coating, and organic coatings. Anodizing involves creating an oxide layer on the surface of the aluminum, providing corrosion resistance and enhancing durability. Powder coating involves applying a dry powder to the aluminum surface and then curing it to create a protective and decorative layer. Organic coatings, such as paints or lacquers, can be applied to aluminum sheets to provide color, protection, and aesthetic appeal.

Send your message to us

Mill Finished Aluminum Sheets 48 X 96 for Building Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords