4x8 Sheets of Aluminum 090 Thick for Building Curtain Walls - Color Coating Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Color Coating Aluminium Sheet for Building Curtain Walls

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC AA8011 AA8006 AA8079 ETC |

TEMPER | H14,H16,H18,H22,H24,H26,H32,O/F |

THICKNESS | 0.03MM-3.0MM |

WIDTH | 30mm-1700mm |

COIL WGT | 2Mt - 3Mt |

COIL ID | φ508mm,φ610mm |

SURFACE | PE ,PVDF , EPOXY,16-25MICRON PAINTING THICK, MAX 40MICRONS |

STANDARD | GB/T 17748-1999 |

2. Application of Color Coating Aluminium Sheet for Building Curtain Walls

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Color Coating Aluminium Sheet for Building Curtain Walls

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

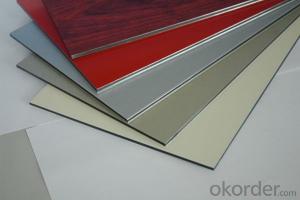

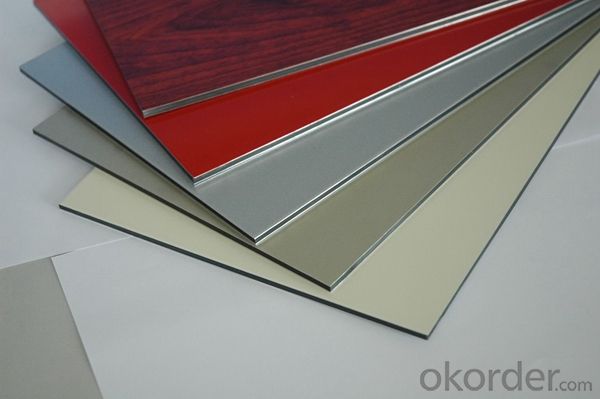

5. Image of Color Coating Aluminium Sheet for Building Curtain Walls

6. Package and shipping of Color Coating Aluminium Sheet for Building Curtain Walls

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: This question asks if aluminum sheets are appropriate for use in regions with cold temperatures.

- <p>Aluminum sheets are generally suitable for use in cold climates. They have excellent resistance to corrosion and maintain their structural integrity in low temperatures. However, aluminum is a good conductor of heat, so it can be prone to heat loss if not properly insulated. For outdoor applications in cold climates, it's important to ensure that aluminum structures are well-insulated to prevent heat transfer. Additionally, aluminum's malleability can make it susceptible to denting or damage from ice and snow, so protective measures may be necessary.</p>

- Q: What are the different methods of surface treatment for aluminum sheets?

- Some of the different methods of surface treatment for aluminum sheets include anodizing, powder coating, painting, polishing, and brushing.

- Q: Are the aluminum sheets suitable for manufacturing transportation containers?

- Yes, aluminum sheets are suitable for manufacturing transportation containers. Aluminum is a widely used material in the transportation industry due to its excellent properties. It is lightweight, yet strong and durable, making it ideal for containers that need to be transported over long distances. Aluminum sheets also have good corrosion resistance, which is crucial for containers that may be exposed to different weather conditions during transportation. Additionally, aluminum is easily recyclable, making it an environmentally friendly choice for manufacturing transportation containers. Overall, aluminum sheets provide the necessary strength, durability, and corrosion resistance required for manufacturing transportation containers.

- Q: What are the different methods of surface protection for aluminum sheets?

- Aluminum sheets can be protected in various ways to ensure their longevity and functionality. Anodizing is a widely used technique, involving the creation of a protective oxide layer on the aluminum surface. This is achieved by immersing the sheets in an electrolyte solution and passing an electric current through them. The outcome is a resilient and corrosion-resistant layer that can be further enhanced with different dyes and sealants. Another option is powder coating, which entails applying a dry powder onto the aluminum sheets and then curing it with heat. This results in a robust coating that offers excellent defense against scratches, chemicals, and weathering. Powder coating is available in a wide array of colors and finishes, making it a popular choice for decorative purposes. Chemical conversion coating is yet another alternative, involving the treatment of aluminum sheets with a chemical solution to convert the surface into a protective layer. This coating not only improves corrosion resistance but also provides a suitable base for paint or other coatings. Painting is a commonly utilized method for safeguarding aluminum sheets. Different types of paints, such as epoxy, acrylic, and polyurethane-based coatings, can be applied to the surface. These paints not only shield against corrosion and environmental factors but also offer the opportunity for aesthetic customization. Lastly, laminating is a technique where a protective film is applied to the surface of the aluminum sheets. These films can be made from various materials like PVC, polyester, or polyethylene. Laminating adds an extra layer of protection against scratches, abrasion, and UV radiation. Each method of surface protection for aluminum sheets has its own merits and considerations, which depend on the specific requirements of the application. It is crucial to thoroughly assess the desired level of protection, aesthetic preferences, and budget constraints before selecting the most suitable method.

- Q: Are aluminum sheets suitable for electrical transformers?

- Yes, aluminum sheets are suitable for electrical transformers. Aluminum has excellent electrical conductivity, lightweight properties, and good thermal conductivity, making it an ideal choice for transformer applications. Additionally, aluminum is cost-effective and readily available, further contributing to its suitability for use in electrical transformers.

- Q: Can aluminum sheets be reused or recycled after their initial use?

- <p>Yes, aluminum sheets can be recycled again after use. Aluminum is one of the most recycled materials globally due to its low cost of recycling and its ability to retain its properties even after multiple recycling processes. Recycling aluminum saves energy compared to producing new aluminum from raw materials, and it helps reduce waste in landfills.</p>

- Q: I need to make an aluminum cylinder out of 1/8 6061 plate and tube. I don't have a TIG setup and was considering using Bernzomatic aluminum soldering rods. The cylinder will be pressurized from 20-60 psi. Assuming a clean job, is this pressure ok? How much pressure can the joint take? Also, although the solder does not need flux, should i use it anyway?

- to your setup i might merely persist with the iron. It would not sound like the burden mark downs is going to be properly actually worth the greater suitable probability for a on a regular basis motive force. forged iron is merely greater rugged and can take greater abuse than aluminum. Aluminum has its place yet its no longer in a on a regular basis motive force like it variety of feels you're development.

- Q: Can aluminum sheets be used for boat building?

- Boat building can indeed incorporate aluminum sheets. The lightweight quality, durability, and resistance to corrosion make aluminum a favored material for constructing boats. Small recreational boats, larger yachts, and even commercial vessels commonly employ aluminum sheets in their construction. These sheets offer numerous benefits, including ease of manipulation, a remarkable strength-to-weight ratio, and minimal upkeep requirements. Furthermore, aluminum boats are esteemed for their exceptional buoyancy, stability, and fuel efficiency. All in all, utilizing aluminum sheets is a suitable and dependable choice for boat building.

- Q: Can aluminum sheets be anodized with custom designs?

- Yes, aluminum sheets can be anodized with custom designs. Anodizing is a process that creates a protective oxide layer on the surface of aluminum, and this layer can be dyed or printed with custom designs before sealing, allowing for personalized and decorative finishes on aluminum sheets.

- Q: Aluminum plate belongs to steel or non ferrous metal?

- Of or consisting of pure aluminum or aluminum alloy material made by pressing (cutting or sawing); a rectangular material with a rectangular cross section and a uniform thickness. See China ferroalloy on line

Send your message to us

4x8 Sheets of Aluminum 090 Thick for Building Curtain Walls - Color Coating Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords