Aluminum Foil For Packaging

Aluminum Foil For Packaging Related Searches

Aluminum Foil For Food Aluminum Foil For Baking Aluminum Foil Packs Food Packaging Aluminum Foil Wrapping With Aluminum Foil Aluminum Foil For Shielding Aluminum Foil For Roofing Aluminum Foil For Insulation Aluminum Wrapping Foil Aluminum Foil For Walls Aluminum Paper Foil Aluminum Foil For Cable Aluminum Foil Wrap Aluminum Foil For Plants Aluminum Foil Packets Aluminum Foil For Smoking Aluminum Container Foil Aluminum Foil For Flies Aluminum Foil For Medicine Buy Aluminum Foil Printed Aluminum Foil Aluminum Foil For Sale Aluminum Foil Bulk Aluminum Foil For Dryer Glue For Aluminum Foil Aluminum Foil For Cake Aluminum Foil For Ceiling Aluminum Foil Pouch Aluminum Foil Food Wrap Box Of Aluminum FoilAluminum Foil For Packaging Supplier & Manufacturer from China

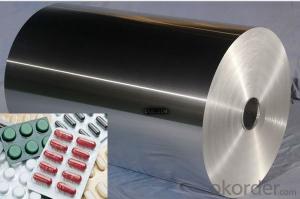

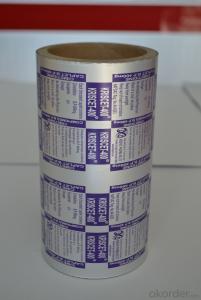

Aluminum foil for packaging is a versatile and widely used material, known for its lightweight, durability, and excellent barrier properties. This product is crafted from high-quality aluminum, which provides a strong shield against air, moisture, and light, ensuring that the contents remain fresh and protected. It is commonly utilized for food packaging, pharmaceuticals, and various industrial applications due to its ability to preserve the quality and integrity of the packaged items.The application and usage scenarios of aluminum foil for packaging are extensive, making it an indispensable material in many industries. It is used for wrapping food items to maintain freshness, protecting pharmaceuticals from moisture and light exposure, and for sealing various products to prevent tampering. Its heat resistance and malleability also make it ideal for cooking and baking purposes, as it can be easily shaped and folded to fit various containers and shapes. Additionally, aluminum foil for packaging is an eco-friendly choice, as it is recyclable and has a lower carbon footprint compared to other packaging materials.

Okorder.com is a reputable wholesale supplier of aluminum foil for packaging, boasting a large inventory that caters to the diverse needs of various industries. They offer competitive prices and reliable service, ensuring that customers receive high-quality products promptly. With their extensive range of aluminum foil for packaging, Okorder.com is the go-to destination for businesses looking to source this essential material in bulk.

Hot Products