Aluminum Gutter Profiles - Alu Perfil de Aluminio

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetal with appearance ranging from silvery to dull gray,depending on the surface roughness. It is nonmagnetic and does not easilyignite. A fresh film of aluminium serves as a good reflector (approximately92%) of visible light and an excellent reflector (as much as98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffnessof steel. It iseasily machined,cast, drawn and extruded.

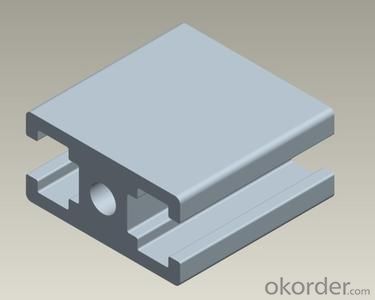

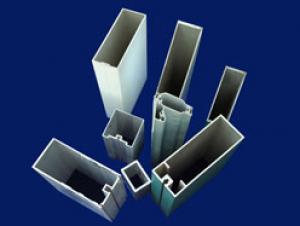

Alu Profile:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C at sight

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Guangzhou/Shenzhen port

4. Delivery time?

15-20 days after client’s deposit

- Q: Can aluminum profiles be used for modular office partitions?

- Yes, aluminum profiles can be used for modular office partitions. Aluminum profiles are lightweight, durable, and have high strength-to-weight ratio, making them an ideal choice for creating modular office partitions. They can be easily fabricated into various shapes and sizes, allowing for customization and flexibility in design. Additionally, aluminum profiles offer excellent corrosion resistance, ensuring long-lasting performance even in high humidity environments. They also provide good thermal and sound insulation properties, contributing to a comfortable and efficient office environment. Overall, aluminum profiles are a popular choice for modular office partitions due to their versatility, durability, and aesthetic appeal.

- Q: What are the standard dimensions of aluminum profiles?

- The specific industry and application can cause the standard dimensions of aluminum profiles to vary. Nevertheless, there are commonly available standard dimensions. Aluminum profiles are generally offered in a range of shapes and sizes, such as rectangular, square, circular, and customized shapes. Rectangular aluminum profiles typically have widths between 1 inch and 6 inches, and heights between 1/2 inch and 4 inches. Square profiles often have widths and heights ranging from 1 inch to 4 inches. Circular aluminum profiles, also referred to as tubes or pipes, usually come in different outer diameters, ranging from 1/4 inch to 8 inches, with wall thicknesses varying from 1/16 inch to 1/2 inch. It is important to note that these dimensions are general standards, and there may be variations depending on the manufacturer and specific project requirements. Additionally, custom dimensions can be manufactured to meet unique specifications. To ensure the chosen dimensions can adequately support the intended use, it is crucial to consider the intended application and load-bearing requirements when selecting aluminum profiles.

- Q: how to determine its value? After these scrap to foundry on the 30...Emergency: the scrap aluminum production enterprises how to conduct accounting treatment, how to determine its value? After the aluminum foundry to exchange into ingots, to pay the processing fee to enter

- The cost of scrap is usually included in the cost of the product. Therefore, the sale of scrap, only income, there is no cost. If the need for management, the establishment of "raw materials - Waste - XXX" can also be. Examples are as follows:1, March 5th workshop in accordance with product production needs. Lead aluminum 1000kg, the unit price is 23.4567 yuanBorrow: production cost - direct material 23456.70Credit: raw materials, -XX profiles, 1000kg 23456.702 and March 25th, the waste generated by the workshop 20kg into the waste warehouse, according to the market price of 5 yuan /kg valuation, according to retire the library for accounting treatmentBorrowing: production costs - direct material -100Credit: raw materials - Scrap - profiles -20kg, -1003 and March 27th, the stock 1200kg scrap sent to the foundry for aluminum ingot, ingot factory price 6 yuan /kgBy: accounts receivable - foundries 7200Credit: other business income + tax 72004, March 27th, scrap exchange aluminum ingot 1050kg, unit price 8 yuan /kg, separately pay processing fee 1200 yuanBorrow: raw material - aluminium ingot 10508400Credit: accounts receivable - foundries 7200Accounts payable - foundries 1200Payment of processing fees (differentials)By: accounts payable 1200Cash: 1200

- Q: How do aluminum profiles perform in terms of energy efficiency?

- Aluminum profiles have excellent energy efficiency performance due to their inherent properties. They are lightweight, durable, and can be easily shaped to optimize thermal insulation. Additionally, aluminum profiles can accommodate double or triple glazing, which further enhances their energy efficiency by minimizing heat transfer and reducing energy consumption for heating or cooling.

- Q: This question asks for a comparison of the benefits and drawbacks of utilizing aluminum profiles in the construction of roofs.

- <p>Aluminum profiles in roofing offer several advantages, including their lightweight nature which reduces structural load, high corrosion resistance making them suitable for various climates, and ease of installation which can lower labor costs. They also have a long lifespan and can be recycled, contributing to sustainability. However, there are disadvantages such as higher initial costs compared to traditional materials, potential for dents or damage from impacts, and the need for regular maintenance to preserve their finish and prevent fading. Additionally, aluminum can be noisy during rain or hail, and it may not be as thermally efficient as some other roofing materials, potentially requiring additional insulation.</p>

- Q: What are the different shapes and sizes of aluminum profiles available?

- A diverse selection of shapes and sizes of aluminum profiles are accessible to accommodate different industrial and architectural needs. Some frequently encountered shapes of aluminum profiles comprise: 1. T-shape: These profiles possess a T-shaped cross-section, consisting of a horizontal top and a vertical stem. They are commonly utilized in framing and structural applications. 2. U-shape: U-shaped profiles exhibit a U-shaped cross-section, featuring two parallel horizontal arms and a connecting vertical stem. They are often employed as edge trims or decorative moldings. 3. L-shape: L-shaped profiles display a right-angle cross-section, with one arm longer than the other. They are frequently used as brackets or corner guards. 4. Square: Square profiles exhibit equivalent width and depth, resulting in a square-shaped cross-section. They offer versatility and can be applied for various purposes, such as frames, supports, or enclosures. 5. Rectangular: Rectangular profiles possess unequal width and depth, forming a rectangular cross-section. They are commonly utilized for structural intentions, like beams or frames. 6. Round: Round profiles showcase a circular cross-section and are commonly employed for applications necessitating a curved or smooth finish, such as handrails or decorative elements. Furthermore, aluminum profiles are obtainable in an assortment of sizes, ranging from diminutive dimensions suitable for lightweight applications to larger sizes for heavy-duty usage. The measurements of aluminum profiles are determined by their width, depth, and thickness, which can be personalized based on specific project requirements. In summary, the broad range of shapes and sizes of aluminum profiles allows for adaptability and versatility in design and construction, ensuring the availability of an appropriate profile for every application.

- Q: This question asks if aluminum profiles can be utilized for the purpose of exterior wall insulation.

- <p>Yes, aluminum profiles can be used for exterior wall insulation. They are often used as a component in various insulation systems due to their durability, lightweight, and resistance to corrosion. Aluminum profiles provide a structural framework that can support insulation materials like mineral wool or polystyrene boards. They also facilitate the attachment of cladding, which can enhance the building's energy efficiency and weather resistance. However, it's important to ensure proper installation and compatibility with other materials in the insulation system to achieve optimal thermal performance.</p>

- Q: Features of aluminum profiles

- Thermal conductivityThe thermal conductivity of aluminum alloy is about 50-60% of copper, which is beneficial to the manufacture of heat exchangers, evaporators, heating appliances, cooking utensils, and the cylinder head and radiator of automobiles.FerromagnetismAluminum is non ferromagnetic, which is an important feature of the electrical and electronic industries. Aluminum can not be spontaneous combustion, which is involved in loading and unloading or exposure to flammable and explosive materials is important.

- Q: What are the different shapes available for aluminum profile cross-sections?

- There are several different shapes available for aluminum profile cross-sections, depending on the specific application and requirements. Some common shapes include: 1. Square: This shape features equal sides and right angles, making it suitable for applications where stability and strength are important, such as structural framing. 2. Rectangular: Similar to square profiles, rectangular profiles have unequal sides and can be used in a wide range of applications, including enclosures, frames, and supports. 3. T-shaped: This shape consists of a central vertical section with a horizontal section extending from one side, resembling the letter "T." T-shaped profiles are often used for joining two components or for providing additional support to structures. 4. L-shaped: L-shaped profiles have a 90-degree angle and are commonly utilized as brackets, corner reinforcements, or frame components. 5. Round: Round aluminum profiles have a circular cross-section and are frequently employed in applications where a smooth, curved appearance is desired, such as handrails, furniture, or decorative elements. 6. I-beam: Resembling the letter "I," these profiles have a central vertical section (known as the web) and two horizontal sections (known as the flanges). I-beams are widely used in construction and structural engineering due to their high strength-to-weight ratio. 7. U-channel: U-channel profiles have a U-shaped cross-section and are often used as edge protectors, trim, or guides. They can also be utilized as tracks for sliding doors or as reinforcement beams. 8. Hexagonal: Hexagonal profiles have six sides and can be used in applications where increased strength and rigidity are required, such as machinery frames or support structures. These are just a few examples of the different shapes available for aluminum profile cross-sections. It is important to choose the most appropriate shape based on the specific requirements of the intended application to ensure optimal performance and functionality.

- Q: RT: you! What are coated aluminum profiles? What's the surface treatment? What's the difference between grain transfer and wood grain transfer? Thank you first!!!

- Coated aluminum is a coating on the surface of aluminum.Aluminum Alloy substrate coated aluminum itself color is silver white, but a long time, Aluminum Alloy surface will be oxidized into a dark gray or black. In order to solve this problem, it is more common to spray a layer of powder (high temperature treatment) on the surface, that is electrostatic powder spraying. Also, fluorocarbon electrophoresis processing processing, transfer grain processing, the market there is a film treatment, with high fidelity, but because the process requirements must be done in the film before powder spraying treatment, the higher requirement to the film itself.

Send your message to us

Aluminum Gutter Profiles - Alu Perfil de Aluminio

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords