Adjustable Arced Steel for Formwork and Scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

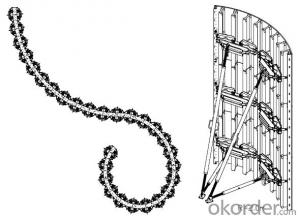

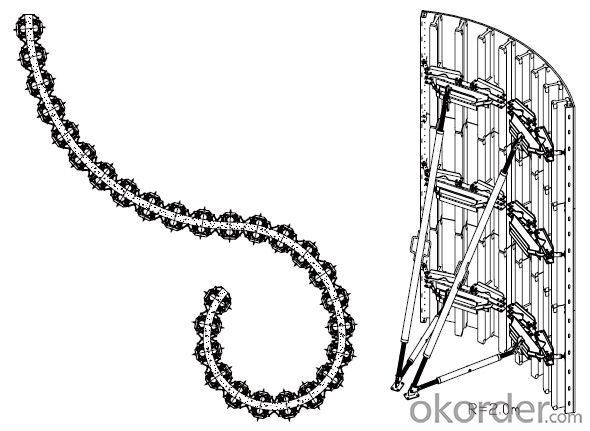

Adjustable Arced Formwork

For pouring arced wall or column with radius more than 1m.

Characteristics:

◆ Adjustable radius, flexible application.

◆ Easy operating, economical efficiency.

- Q: What are the different quality control measures for steel formwork construction?

- Steel formwork construction commonly implements several quality control measures to guarantee the quality and integrity of the final product. Some of these measures include: 1. Inspection of materials: Prior to commencing construction, thorough inspections are conducted on all steel formwork materials to ensure they meet the necessary specifications and standards. This entails checking for defects, such as cracks or deformations, and verifying the quality of the steel used. 2. Welding inspections: Welding is often required to join different components of steel formwork structures. Regular inspections are crucial to ensure that all welded joints are executed properly and meet the required strength and quality standards. This involves checking for proper penetration, weld size, and alignment, as well as conducting non-destructive testing if necessary. 3. Dimensional checks: Accurate dimensions are vital for the proper assembly and functionality of steel formwork structures. Throughout the construction process, regular dimensional checks are conducted to ensure that all components are fabricated to the correct specifications. This includes verifying the lengths, widths, and thicknesses of plates, beams, and other structural elements, as well as checking for proper alignment and positioning. 4. Surface finish inspection: The surface finish of steel formwork components significantly affects their performance and durability. Regular inspections are carried out to ensure that all surfaces are free from defects such as roughness, cracks, corrosion, or any other imperfections that could compromise the structure's integrity. 5. Load testing: Load testing is a crucial quality control measure for steel formwork construction. It involves subjecting the formwork structures to a predetermined load to ensure they can withstand the expected forces during use. Load testing can be performed using various methods, including static or dynamic load tests, and helps ensure the structural stability and safety of the formwork. 6. Documentation and record keeping: Proper documentation and record keeping of all quality control measures performed during steel formwork construction are essential. This includes recording the results of inspections, tests, and any corrective actions taken. Documentation facilitates traceability, provides a reference for future inspections, and ensures compliance with relevant standards and regulations. By implementing these quality control measures, steel formwork construction companies can guarantee that their structures meet the required standards, are safe and durable, and provide reliable support during the concrete pouring process.

- Q: What are the different types of coatings available for steel formwork?

- Steel formwork has a variety of coatings available, each with its own unique advantages and applications. 1. Paint coatings: These coatings offer basic corrosion protection and can be applied in different colors. They are affordable and easy to apply, making them a popular choice for general-purpose formwork. 2. Galvanized coatings: Galvanizing involves applying a zinc layer to the steel surface, providing excellent corrosion resistance. It is ideal for formwork in harsh environments or requiring long-term durability. 3. Epoxy coatings: Epoxy coatings provide superior chemical resistance and durability compared to other coatings. They are commonly used in formwork exposed to aggressive substances or requiring high hygiene standards, like in the food industry. 4. Powder coatings: Powder coatings are applied as a dry powder and then baked, resulting in a hard, durable finish. They have excellent impact resistance and come in a wide range of colors. They are often used in formwork subject to significant wear and tear. 5. Polymer coatings: Polymer coatings, such as polyurethane or polyethylene, create a protective layer over the steel surface. They offer good resistance to abrasion, impact, and chemicals, making them suitable for demanding applications. 6. Thermal spray coatings: Thermal spray coatings involve applying molten materials like zinc or aluminum onto the steel surface. They provide exceptional corrosion resistance and are commonly used in marine or offshore formwork. When choosing the right coating for steel formwork, it is important to consider factors such as intended use, environmental conditions, and budget. Consulting coating specialists or manufacturers can help determine the best coating for specific applications.

- Q: How does steel formwork affect the overall durability of a construction project?

- Steel formwork can have a significant impact on the overall durability of a construction project. One of the key advantages of using steel formwork is its strength and durability. Steel is known for its high tensile strength, which allows it to withstand heavy loads and resist deformation. This strength is crucial in ensuring that the formwork maintains its shape and integrity throughout the construction process. Additionally, steel formwork is highly resistant to wear and tear, making it suitable for multiple uses and reuses. Unlike other materials such as wood, steel does not easily degrade or deteriorate, ensuring that the formwork remains in good condition for long periods. This durability is particularly important in large-scale construction projects that require repetitive formwork installations. Moreover, steel formwork offers excellent dimensional stability. It does not warp or shrink under varying weather conditions, which helps to maintain the accuracy and precision of the concrete structure being formed. This is crucial for ensuring that the final construction project meets the required specifications and standards. The durability of steel formwork also contributes to the overall safety of the construction project. Its strength and stability prevent any potential formwork failure, which could lead to accidents or structural damages during the concrete pouring process. By providing a secure and reliable support system, steel formwork enhances the safety of workers and the long-term structural integrity of the building. Furthermore, the durability of steel formwork translates into cost-effectiveness over the project's lifespan. Its ability to be reused reduces the need for constant replacement, saving time and money on material expenses. Additionally, the reduced maintenance required for steel formwork lowers ongoing maintenance costs, making it a cost-effective choice for construction projects. In conclusion, steel formwork greatly contributes to the overall durability of a construction project. Its strength, resistance to wear and tear, dimensional stability, and safety features ensure that the formwork remains intact throughout the construction process. This durability not only enhances the structural integrity of the building but also provides cost-effectiveness and peace of mind for the project stakeholders.

- Q: What are the different types of steel formwork available?

- There are several types of steel formwork available in the construction industry, each with its own unique features and advantages. Some of the most common types include: 1. Modular steel formwork: This type of formwork consists of prefabricated steel panels that can be assembled and disassembled easily. It is customizable and can be used for various shapes and sizes of concrete structures. 2. Tunnel formwork: As the name suggests, tunnel formwork is used for constructing tunnels and underground structures. It is made of steel plates and is designed to withstand high pressure and provide a smooth finish to the concrete. 3. Climbing formwork: This type of formwork is used for tall structures like skyscrapers. It is designed to be lifted and moved vertically as the construction progresses. Climbing formwork provides safety and efficiency while constructing multi-story buildings. 4. Steel soldier formwork: This is a versatile and cost-effective type of formwork that is commonly used for walls and columns. It is made of steel beams and soldiers and can be easily adjusted to different heights and widths. 5. Steel frame formwork: This type of formwork is made of steel frames with plywood or metal panels attached to it. It is lightweight, easy to handle, and provides a smooth finish to the concrete. 6. Steel table formwork: This is a type of formwork that is used for large horizontal slabs. It consists of steel tables that are supported by props or scaffolding. Steel table formwork is quick to assemble and dismantle, making it ideal for projects with tight timelines. These are just a few examples of the different types of steel formwork available. The choice of formwork depends on the specific requirements of the construction project, such as the type of structure, load-bearing capacity, and desired finish.

- Q: Can steel formwork be used for structures with high chemical resistance requirements?

- Structures with high chemical resistance requirements are not suitable for steel formwork. Steel is susceptible to corrosion and lacks resistance to numerous harsh chemicals, which can cause deterioration and compromise the structural integrity of the formwork. Consequently, the stability and safety of the structure may be compromised. To guarantee the structure's longevity and durability in environments with significant chemical exposure, alternative materials such as chemically resistant plastics or composites should be contemplated.

- Q: Can steel formwork be used for both monolithic and composite construction?

- Yes, steel formwork can be used for both monolithic and composite construction.

- Q: What are the common safety certifications for steel formwork systems?

- The common safety certifications for steel formwork systems include ISO 9001:2015, OHSAS 18001, and EN 12811-1.

- Q: What are the considerations when designing steel formwork for slabs with openings?

- When designing steel formwork for slabs with openings, several important considerations need to be taken into account. These include: 1. Load-bearing capacity: The formwork must be able to support the weight of the concrete, as well as any additional loads that may be placed on it during construction or use. The formwork should be designed to withstand these loads without experiencing excessive deflection or failure. 2. Durability: Steel formwork should be designed to withstand the harsh conditions of construction sites, including exposure to moisture, chemicals, and physical impact. The material chosen should be resistant to corrosion and have a high strength-to-weight ratio. 3. Flexibility and adjustability: Since slabs with openings often have irregular shapes and sizes, the formwork should be designed to be flexible and adjustable. This allows for easy customization and ensures a precise fit for the openings. 4. Support for reinforcement: The formwork should provide adequate support for the reinforcement bars or mesh used within the slab. It should be designed to accommodate the placement and spacing of these reinforcements, ensuring proper concrete cover and structural integrity. 5. Ease of assembly and disassembly: The formwork system should be designed for easy assembly and disassembly, as it needs to be repeatedly used for multiple slabs with openings. The components should be lightweight and easily maneuverable, allowing for efficient construction and reduced labor costs. 6. Safety: Safety is of utmost importance in the design of steel formwork. The formwork should be designed to prevent accidents, such as slipping or collapsing, during assembly, concrete pouring, and removal. Adequate safety measures, such as guardrails and non-slip surfaces, should be incorporated into the design. 7. Cost-effectiveness: The design should aim to minimize material and labor costs while still ensuring the required strength and durability. Efficient use of materials and standardization of components can help reduce overall costs. 8. Compatibility with other construction systems: The formwork should be compatible with other construction systems, such as scaffolding or shoring, to ensure proper integration and coordination during the construction process. By considering these factors, designers can create steel formwork systems that are safe, durable, cost-effective, and efficient for slabs with openings.

- Q: What are the considerations when designing steel formwork for retaining walls?

- When designing steel formwork for retaining walls, several important considerations should be taken into account: 1. Structural stability: The primary function of a retaining wall is to retain soil or other materials. Therefore, the steel formwork must be designed to withstand the lateral pressure exerted by the retained material. Adequate thickness, reinforcement, and bracing should be incorporated to ensure structural stability. 2. Load capacity: The formwork should be designed to support the weight of the concrete and any additional loads imposed during construction, such as equipment or workers. The steel formwork should be able to withstand these loads without deformation or failure. 3. Durability: Retaining walls are exposed to various environmental conditions, including moisture, temperature changes, and chemical exposure. The steel formwork should be designed to resist corrosion, rust, and other forms of deterioration over time. This may involve using corrosion-resistant steel or applying protective coatings. 4. Ease of construction: The design of the steel formwork should take into consideration the ease of assembly and disassembly. It should be structurally sound yet easy to install and remove. This will help save time and labor during construction. 5. Flexibility: Retaining walls may have different geometries and dimensions depending on the specific site conditions and design requirements. The steel formwork should be flexible enough to accommodate these variations. Adjustable connections or modular components can be used to achieve this flexibility. 6. Safety: Safety should be a top priority when designing steel formwork for retaining walls. Proper consideration should be given to factors such as fall protection, access, and working platforms to ensure the safety of workers during construction. 7. Cost-effectiveness: The design of the steel formwork should be optimized to minimize material usage and labor costs while still meeting the required strength and durability. This may involve using standard sizes and components, as well as incorporating reusable elements that can be utilized for multiple projects. By considering these factors, designers can ensure that the steel formwork for retaining walls is not only structurally sound and durable but also efficient and cost-effective.

- Q: Are there any specific design considerations for steel formwork systems?

- Yes, there are several specific design considerations for steel formwork systems. Firstly, the design of steel formwork systems should consider the load-bearing capacity of the structure. Steel formwork systems should be designed to withstand the weight of the concrete being poured, as well as any additional loads such as workers or construction equipment. The design should ensure that the steel formwork is strong enough to support these loads without any deformation or failure. Secondly, the design of steel formwork systems should take into account the dimensional accuracy and stability requirements of the concrete structure. Steel formwork systems need to be designed with precision and accuracy to ensure that the final concrete structure meets the desired specifications. The formwork should be rigid and stable, preventing any movement or shifting during the concrete pouring and curing process. Additionally, the design of steel formwork systems should consider the ease of assembly, disassembly, and reusability. Steel formwork systems are typically assembled and disassembled multiple times throughout a construction project. Therefore, the design should allow for easy and efficient installation and removal, minimizing downtime and labor costs. Furthermore, the steel formwork should be durable and reusable, reducing the need for frequent replacement and contributing to cost savings. Lastly, the design of steel formwork systems should consider safety aspects. The formwork should be designed to provide a safe working environment for construction workers. This includes features such as non-slip surfaces, guardrails, and safety barriers to prevent falls or accidents. The design should also incorporate proper access and egress points, ensuring easy movement for workers within the formwork system. In summary, specific design considerations for steel formwork systems include load-bearing capacity, dimensional accuracy, ease of assembly and reusability, and safety features. By taking these factors into account, designers can ensure the successful and efficient construction of concrete structures using steel formwork systems.

Send your message to us

Adjustable Arced Steel for Formwork and Scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords