Steel-frame Formwork system SF-140

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

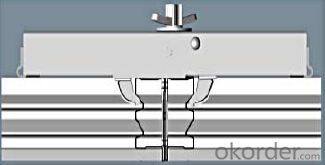

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

◆ Kinds of panel connectors.

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: What are the considerations when designing steel formwork for columns?

- There are several important factors to consider when designing steel formwork for columns. These factors include the size and shape of the column, the load it will bear, the height of the column, the desired finish of the concrete, and the availability of labor and equipment. To begin with, the dimensions and configuration of the formwork will be determined by the size and shape of the column. The formwork must be able to accommodate the specific dimensions of the column, including its diameter or width, as well as its height. It may need to be adjustable or modular to fit different column sizes and shapes. Additionally, the ability of the formwork to withstand the weight of the concrete and any additional loads is crucial. It must be designed to support the weight without deforming or failing, ensuring the structure's integrity and safety. The height of the column is also a consideration in formwork design. Tall columns may require extra support or bracing to prevent buckling or collapsing. The formwork should be designed to provide sufficient stability and strength throughout the column's height. Furthermore, the desired finish of the concrete is an important factor to keep in mind. If a smooth or architectural finish is desired, the formwork must be designed to create a smooth and even surface. This might involve using special form liners or coatings to achieve the desired finish. Lastly, the availability of labor and equipment should be taken into account. The formwork design should consider how easy it is to assemble, disassemble, and transport. It should be practical and efficient to install and dismantle, taking into consideration the labor and equipment available on the construction site. In conclusion, when designing steel formwork for columns, it is important to consider the size and shape of the column, the load it will bear, the height of the column, the desired concrete finish, and the availability of labor and equipment. By carefully considering these factors, the formwork can be designed to meet the specific requirements of the project, ensuring a safe and efficient construction process.

- Q: Can steel formwork be easily modified or adjusted during construction?

- Yes, steel formwork can be easily modified or adjusted during construction. Steel formwork is known for its flexibility and adaptability, allowing for quick and convenient adjustments as per the project requirements. Steel formwork systems are designed to be modular, which means they can be easily assembled and disassembled, allowing for easy modification or adjustment of the formwork structure. Additionally, steel formwork can be easily cut, welded, or bolted together to create custom formwork shapes or sizes. This versatility of steel formwork makes it a preferred choice in construction projects where modifications or adjustments are frequently required.

- Q: How is steel formwork transported to the construction site?

- Depending on the distance, quantity, and accessibility of the construction site, steel formwork is transported using different methods. Truck transportation is a common choice for shorter distances and smaller quantities. This involves loading the steel formwork components onto a flatbed or trailer and driving them to the site. For larger quantities or longer distances, rail or sea transportation may be used. Rail transport is efficient for moving large quantities over long distances, especially when the site is far from the manufacturing facility. On the other hand, sea transport is ideal for international projects that require shipping the formwork overseas. The formwork is loaded into shipping containers and transported by cargo ships. Upon arrival at the construction site, cranes or forklifts are used to unload the steel formwork. The components are then stored in a designated area until they are ready for installation. It is crucial to carefully plan and execute the transportation process to prevent any damage to the formwork. Any issues with structural integrity can adversely affect the quality and safety of the final construction project.

- Q: How does steel formwork impact the overall energy efficiency of a structure?

- Steel formwork can have a significant impact on the overall energy efficiency of a structure. Firstly, steel formwork is highly durable and can be used repeatedly, reducing the need for new formwork materials for each construction project. This reduces the energy consumption associated with manufacturing and transporting formwork materials. Furthermore, steel formwork is known for its excellent thermal conductivity, which allows for efficient heat transfer. This property is particularly important in structures where energy efficiency is a priority, such as residential or commercial buildings. Efficient heat transfer can help maintain a comfortable indoor temperature, reducing the need for excessive heating or cooling, and thus minimizing energy consumption. In addition, steel formwork can contribute to the overall insulation of a structure. By using insulating materials in combination with steel formwork, a building's thermal performance can be significantly improved. This insulation helps to prevent heat loss during colder months and heat gain during warmer months, reducing the reliance on artificial heating and cooling systems. Consequently, energy consumption is reduced, leading to improved energy efficiency. Moreover, steel formwork can be designed to incorporate features that enhance natural lighting and ventilation in a structure. By allowing more natural light to enter the building, the need for artificial lighting during daylight hours is reduced, resulting in lower energy consumption. Similarly, by promoting natural ventilation, steel formwork can reduce the need for mechanical ventilation systems, further contributing to energy efficiency. Lastly, steel formwork's strength and stability allow for the construction of innovative and energy-efficient structural designs. It enables the use of larger open spaces, reducing the need for additional structural components and materials. This not only reduces construction costs but also lowers energy consumption associated with the production and transportation of these additional materials. In conclusion, steel formwork positively impacts the overall energy efficiency of a structure through its durability, thermal conductivity, insulation properties, natural lighting and ventilation features, and its ability to enable innovative structural designs. By reducing energy consumption in various ways, steel formwork contributes to the sustainability and long-term energy efficiency of a building.

- Q: What are the different types of formwork ties used in steel formwork?

- Some of the different types of formwork ties used in steel formwork include snap ties, wedge ties, coil ties, and flat ties. These ties are used to secure the formwork panels together and provide stability during the concrete pouring process.

- Q: How does steel formwork contribute to sustainable construction practices?

- Steel formwork contributes to sustainable construction practices in several ways: 1. Durability: Steel formwork is highly durable and can be reused multiple times, reducing the need for frequent replacement. This reduces the amount of waste generated during construction and minimizes the environmental impact associated with producing new formwork materials. 2. Energy efficiency: Steel formwork is known for its high strength-to-weight ratio, which means less material is needed to achieve the same level of structural support compared to other formwork materials. This results in reduced energy consumption during manufacturing and transportation of the formwork components. 3. Waste reduction: Steel formwork can be custom-designed to fit specific project requirements, resulting in minimal waste generation during the construction process. Additionally, the modular nature of steel formwork allows for easy disassembly and reconfiguration, reducing construction waste and enabling efficient recycling or reuse of the materials. 4. Improved construction speed: Steel formwork systems are designed for rapid assembly and disassembly, resulting in faster construction times. This reduces the overall project duration, minimizes disruption to the surrounding environment, and helps conserve resources. 5. Enhanced safety: Steel formwork provides a strong and stable support structure, reducing the risk of accidents or structural failures during construction. This contributes to a safer working environment for construction workers, promoting sustainable practices through improved worker welfare. 6. Recyclability: Steel is one of the most recyclable construction materials, and steel formwork can be easily recycled at the end of its useful life. This promotes a circular economy by reducing the demand for new steel production and minimizing the environmental impact associated with mining and extracting raw materials. Overall, steel formwork's durability, energy efficiency, waste reduction, improved construction speed, enhanced safety, and recyclability make it a sustainable choice for construction practices. By integrating steel formwork into construction projects, builders can contribute to sustainable development by reducing environmental impacts and promoting resource efficiency.

- Q: How does steel formwork handle different weather conditions?

- Known for its durability and resistance to various weather conditions, steel formwork possesses the capacity to withstand extreme temperatures, heavy rain, strong winds, and even snow. One of the primary benefits of steel formwork lies in its ability to endure high temperatures without deformity or loss of structural integrity. This quality renders it suitable for utilization in hot climates where temperatures can soar. Furthermore, steel formwork does not readily absorb heat, enabling it to remain cool to the touch even when exposed to direct sunlight. Moreover, steel formwork exhibits exceptional resistance to heavy rain and water exposure. It does not succumb to rot, warping, or degradation when in contact with water, making it an ideal choice for regions with abundant rainfall or high humidity levels. Furthermore, steel does not readily absorb moisture, effectively preventing the growth of mold or mildew, which can be problematic with other formwork materials. Another advantage of steel formwork lies in its resilience against strong winds. The inherent strength and rigidity of steel render it highly resistant to wind loads. This attribute becomes particularly crucial in areas prone to hurricanes, cyclones, or forceful gusts of wind. Steel formwork provides stability and ensures the structure remains intact even during severe weather conditions. Additionally, steel formwork can effectively handle snow and cold temperatures. It does not crack or become brittle when exposed to freezing temperatures, making it a suitable choice for cold climates. The strength and durability of steel formwork guarantee that it can support the weight of accumulated snow without suffering structural damage. In conclusion, steel formwork stands as a dependable and robust solution capable of effectively managing diverse weather conditions. Its ability to withstand extreme temperatures, heavy rain, strong winds, and snow has contributed to its widespread use in construction projects worldwide.

- Q: How does steel formwork handle different concrete reinforcement types?

- Steel formwork is a versatile and durable option for handling different types of concrete reinforcement. It is commonly used in construction projects to create temporary molds or structures to hold concrete in place during the pouring and curing process. One of the advantages of steel formwork is its ability to handle different concrete reinforcement types. Whether it is traditional reinforcement such as steel bars or modern reinforcement techniques like fiber-reinforced polymers (FRP), steel formwork can accommodate them all. Steel formwork is designed to be strong and rigid, which allows it to support the weight and pressure exerted by different types of reinforcement materials. Whether it is the weight of steel bars or the tensile strength of FRP, steel formwork can withstand these forces without deforming or collapsing. Additionally, steel formwork is highly adaptable and can be easily adjusted or modified to accommodate different reinforcement types. It can be cut or welded to create openings or recesses for steel bars or other reinforcement materials to pass through. This flexibility ensures that steel formwork can be customized to suit the specific needs of each construction project. Furthermore, steel formwork offers a smooth and even surface finish, which is crucial for ensuring proper adhesion between the concrete and the reinforcement materials. This ensures that the reinforcement is securely embedded within the concrete structure, providing the necessary structural integrity and strength. In conclusion, steel formwork is a reliable and effective solution for handling different concrete reinforcement types. Its strength, adaptability, and ability to provide a smooth surface finish make it an ideal choice for construction projects that require diverse reinforcement materials.

- Q: What are the different safety features incorporated in steel formwork systems?

- Steel formwork systems are designed with various safety features to ensure the protection of workers and the overall success of construction projects. Some of the key safety features incorporated in these systems include: 1. Sturdy Construction: Steel formwork systems are made of high-quality steel materials, which provide strength and stability. This robust construction minimizes the risk of collapse or structural failure, ensuring the safety of workers. 2. Adjustable Support Systems: Steel formwork systems are equipped with adjustable support systems, such as props and jacks. These features allow for precise adjustment and leveling, ensuring stability and preventing the formwork from shifting or collapsing. 3. Guardrails and Toe Boards: Steel formwork systems often include guardrails and toe boards as standard safety features. These prevent workers from falling off the edges of the formwork, reducing the risk of accidents and injuries at height. 4. Non-Slip Surfaces: To enhance safety, steel formwork systems are often designed with non-slip surfaces. These surfaces provide better traction and reduce the likelihood of workers slipping or falling, especially in wet or slippery conditions. 5. Safety Accessories: Many steel formwork systems come with additional safety accessories, such as safety nets, harnesses, and personal protective equipment (PPE). These accessories provide further protection for workers, preventing falls and ensuring compliance with safety regulations. 6. Easy Assembly and Dismantling: Steel formwork systems are designed to be easily assembled and dismantled, reducing the time workers spend at height. This minimizes the risk of accidents during construction and promotes efficient workflow. 7. Fire Resistance: Steel formwork systems are often fire-resistant or fire-retardant, enhancing safety in case of fire emergencies. This feature helps to prevent the rapid spread of fire and provides additional time for evacuation or firefighting. 8. Load-Bearing Capacity: Steel formwork systems are engineered to have high load-bearing capacities, allowing them to support heavy concrete loads. This ensures that the formwork can withstand the weight without deformation or failure, enhancing safety during construction. In conclusion, steel formwork systems incorporate various safety features to protect workers and ensure the successful completion of construction projects. From sturdy construction and adjustable support systems to guardrails and non-slip surfaces, these features prioritize worker safety and contribute to a safer working environment.

- Q: Does steel formwork require any special expertise or training for installation?

- Yes, steel formwork does require special expertise and training for installation. Steel formwork is a complex system of interlocking panels and components that are used to create temporary molds for pouring concrete structures. It requires a thorough understanding of the formwork design, installation techniques, and safety procedures. Professionals who work with steel formwork need to be knowledgeable about the specific requirements of each project, including the load-bearing capacity, formwork connections, and the proper placement of reinforcement. They also need to have the skills to accurately measure and cut the steel panels, assemble them correctly, and ensure that the formwork is properly aligned and braced. In addition, expertise in steel formwork installation includes understanding the different types of formwork systems available, such as adjustable steel formwork, modular steel formwork, or tunnel formwork, and knowing how to select the most appropriate system for a particular project. This knowledge is crucial to ensure that the formwork can withstand the pressure exerted by the wet concrete and can produce a structurally sound and aesthetically pleasing final result. Furthermore, proper training in steel formwork installation is essential to ensure the safety of workers and the overall success of the construction project. This includes knowledge of safety regulations, understanding how to use personal protective equipment, and being aware of potential hazards and how to mitigate them. Overall, due to the complexity and specific requirements of steel formwork installation, it is important to have professionals with the necessary expertise and training to ensure a smooth and successful construction process.

Send your message to us

Steel-frame Formwork system SF-140

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords