Adjustable Arced for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

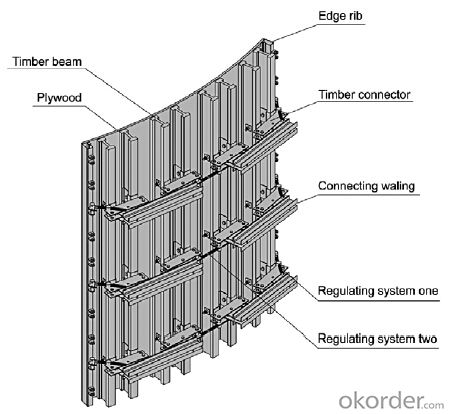

Adjustable Arced Formwork

For pouring arced wall or column with radius more than 1m.

Characteristics:

◆ Adjustable radius, flexible application.

◆ Easy operating, economical efficiency.

- Q: How does steel formwork handle concrete pump pressure?

- Steel formwork is well-suited to handle the pressure exerted by a concrete pump. Steel is a strong and durable material that can withstand high levels of pressure without deforming or failing. The formwork system is designed to distribute the force of the concrete pump evenly throughout the structure, preventing any localized areas of stress concentration. Additionally, steel formwork is rigid and stable, ensuring that it maintains its shape and integrity during the pumping process. This allows for the smooth and efficient flow of concrete, without any risk of the formwork collapsing or buckling under the pressure. Overall, steel formwork is specifically engineered to handle the concrete pump pressure, making it a reliable and safe choice for construction projects.

- Q: What is the maximum load that steel formwork can support?

- The maximum load that steel formwork can support varies depending on factors such as the specific design, quality of steel used, and the support system in place. It is crucial to consult the manufacturer's specifications and engineering calculations to determine the safe maximum load for a particular steel formwork.

- Q: How does steel formwork compare to other formwork materials in terms of cost?

- Compared to timber or plywood, steel formwork generally carries a higher price tag. However, when considering the overall expenses of a construction project, steel formwork has the potential to save costs in the long run. Although the initial cost of steel formwork may be greater, it boasts exceptional durability and can be reused multiple times without compromising its structural integrity. This reusability feature diminishes the need for constant replacement or repair, ultimately reducing the overall expenses for formwork materials in the long term. Furthermore, steel formwork provides unparalleled strength, stability, and precision in shaping concrete structures, resulting in a superior final product. This, in turn, can lead to reduced labor expenses and shorter construction durations, effectively counterbalancing the initial investment in steel formwork. Moreover, steel formwork offers heightened safety due to its fire-resistant properties and ability to withstand extreme weather conditions. This lowers the chances of accidents or damage during the construction process, which can potentially result in savings on insurance costs. Although steel formwork may initially be more costly than alternative materials, it offers a multitude of advantages that can lead to cost savings throughout the entirety of the construction process.

- Q: Can steel formwork be used for both interior and exterior concrete placement?

- Yes, steel formwork can be used for both interior and exterior concrete placement. Steel formwork is known for its durability and strength, making it suitable for various construction projects. It provides a stable and rigid structure that can withstand the pressure and weight of the concrete during the pouring and setting process. Moreover, steel formwork can be easily assembled and disassembled, allowing for efficient use in both interior and exterior applications. Whether it is for building walls, columns, slabs, or other concrete elements, steel formwork offers a versatile solution that can be used in different environments and conditions.

- Q: How does steel formwork handle concrete curing?

- Steel formwork is a popular choice for concrete construction due to its durability and strength. When it comes to handling concrete curing, steel formwork offers several advantages. Firstly, steel formwork provides excellent support and stability to the concrete during the curing process. Its rigid structure ensures that the concrete maintains its desired shape and form, preventing any deformations or bulges. This is particularly crucial in projects that require precise dimensions or intricate designs. Secondly, steel formwork has good heat conductivity, which allows for efficient heat dissipation during concrete curing. This is beneficial as it helps to regulate the temperature of the concrete, preventing excessive heat buildup that could lead to cracks or other structural issues. Steel's ability to quickly dissipate heat also aids in accelerating the curing process, reducing the overall time required for the concrete to achieve its desired strength. Additionally, steel formwork is capable of withstanding the high pressures exerted by the wet concrete during the curing phase. Its robust nature ensures that it does not deform or buckle under the weight of the concrete, maintaining its structural integrity throughout the process. Furthermore, steel formwork is reusable, making it a cost-effective option for handling concrete curing. Once the concrete has sufficiently cured and hardened, the formwork can be easily removed, cleaned, and reused for future projects. This eliminates the need for frequent formwork replacements and reduces construction waste. In summary, steel formwork is well-suited for handling concrete curing due to its stability, heat conductivity, strength, and reusability. It provides excellent support to the concrete, regulates temperature, withstands high pressures, and offers cost savings. These attributes make steel formwork a reliable and efficient choice for ensuring successful concrete curing in construction projects.

- Q: How does steel formwork compare to wooden formwork?

- Steel formwork is often considered superior to wooden formwork due to its numerous advantages. Firstly, steel formwork is highly durable and can withstand heavy loads and repeated use. It does not warp, crack or split like wooden formwork, ensuring a longer lifespan and reduced maintenance costs. Moreover, steel formwork provides greater accuracy and precision in construction. Its rigid structure ensures that the desired dimensions and shapes are maintained, resulting in better-quality finishes. In contrast, wooden formwork can be more challenging to align and may result in slight variations or imperfections in the final product. Steel formwork also offers increased efficiency and productivity. It can be easily assembled, disassembled, and moved to different locations, reducing construction time and labor costs. Additionally, steel formwork requires minimal cleaning and maintenance, eliminating the need for constant repairs or replacements like wooden formwork. Furthermore, steel formwork is more resistant to moisture and weather conditions. It does not absorb water or warp when exposed to rain or humidity, making it suitable for use in various climates. Wooden formwork, on the other hand, can degrade when exposed to moisture, potentially affecting the structural integrity of the construction. Although steel formwork may require a higher initial investment than wooden formwork, its long-term benefits outweigh the costs. It provides greater durability, accuracy, efficiency, and resistance to environmental factors, making it a preferred choice in modern construction projects.

- Q: How does steel formwork handle different concrete durability requirements?

- Steel formwork is a versatile and durable solution that can effectively handle different concrete durability requirements. The strength and rigidity of steel make it ideal for withstanding the pressures and stresses exerted by the concrete being poured. Steel formwork is highly adaptable and can be customized to meet specific durability requirements. This allows for the creation of formwork systems that are capable of withstanding harsh environmental conditions, such as extreme temperatures, moisture, and chemical exposure. Additionally, steel formwork can be designed to accommodate various load-bearing requirements, ensuring that the structure remains stable and secure during and after the concrete casting process. Moreover, steel formwork offers excellent dimensional stability, which is essential for achieving accurate and precise concrete finishes. This is particularly important when constructing structures that require a high level of aesthetic appeal or when intricate architectural designs are involved. Another advantage of steel formwork is its reusability. Unlike other types of formwork, steel can be used multiple times, minimizing waste and reducing overall construction costs. This makes it a cost-effective solution for projects with varying concrete durability requirements, as the formwork can be easily adjusted and reused for different applications. In summary, steel formwork is a reliable and adaptable solution that can effectively handle different concrete durability requirements. Its strength, customizability, dimensional stability, and reusability make it an ideal choice for a wide range of construction projects, ensuring that the concrete structures meet the desired durability standards.

- Q: Who used plastic building template? How is the effect? What are the advantages and disadvantages?

- Plastic building template is an energy-saving and environment-friendly products, after the wooden template, composite steel formwork, bamboo plywood, all steel template and a new type of product. Can completely replace the steel formwork, formwork, timber, traditional energy saving and environmental protection, low cost amortization

- Q: How is steel formwork cleaned and maintained?

- Steel formwork can be cleaned and maintained by removing any concrete residue using a high-pressure water jet or wire brush. After cleaning, it should be inspected for any damages or rust, and if found, repaired or repainted accordingly. Regular lubrication of moving parts and proper storage in a dry environment also helps to extend its lifespan.

- Q: How does steel formwork affect the overall construction budget?

- The overall construction budget can be significantly affected by steel formwork. Although it may have a higher upfront cost compared to timber or plastic formwork, it offers various advantages that can result in long-term cost savings. One major advantage of steel formwork is its durability and reusability. It can withstand multiple uses without compromising its structural integrity, unlike timber or plastic formwork. This means it can be used for multiple construction projects, reducing the need for frequent replacements and lowering material costs over time. Furthermore, steel formwork is known for its high strength and stability, which allows for efficient concrete pouring and ensures precise dimensions. This reduces the risk of errors or reworks, which can cause significant time and cost overruns. Additionally, steel formwork typically requires less labor and time to assemble and dismantle compared to traditional materials. Its modular design and easy installation enable quicker construction progress, resulting in reduced labor costs and improved project efficiency. Moreover, steel formwork offers flexibility in design and customization, making it easy to build complex and intricate structures. This versatility eliminates the need for additional materials or specialized formwork systems, resulting in cost savings. In conclusion, despite its higher initial cost, steel formwork's durability, reusability, strength, and efficiency can lead to cost savings in terms of materials, labor, and time. By considering the long-term benefits and overall efficiency it provides, steel formwork can have a positive impact on the construction budget as a whole.

Send your message to us

Adjustable Arced for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches