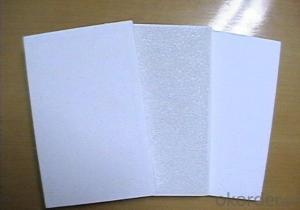

Fiberglass Drop Ceiling Tiles - Acoustic Fiberglass Ceiling, Well Quality, Concealed

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Ceiling

The tiles are manufactured from high density fiberglass wool.The visible face has a decorative fiberglass tissue and the back of the tile is covered with normal tissue.The four edges of the tile are sealed and have grooves. It can be jointed together without suspended system. The tiles will cover the suspension system after installation. They are are suitable for loe flap ceiling space and concrete-made, wooded-made or gymsum ceiling.

Installation method:

Use screw to fix the smooth roof. The tiles can be connected after making grooves on each two jointed edges.

Tiles are easy to trim and install

Both inches and metric grids are available

Main Characteristic:

Non-combustible

No sagging,wrapping or delaminating

Green building material

Excellent sound absorption

Application:

Halls,classrooms,offices,shopping centers.etc.

Acoustic fiberglass ceiling contains a better perfomance in tension strong, light weight, so it is easy to trim and install for interior decoration, with T-grids for suspension system or glue, nail or good material could come with fiberglass ceiling baord. Thus an excellent artical work need a high quality acoustic ceiling board, also high quality.

Energysaving is a trend for our 21' era, new product like fiberglass ceiling tile could in place of traditional products one day. Which depends on functional characters: little deflection of geometry dimention, no radiocative property, specific activity of 226Ra: Ira ≤1.0 and specific activity of 226 Ra 232 Th, 40 K: Ir ≤ 1.3. Both products and packages can be recycled.

- Q: Home want to stick wallpaper, what kind of election is better

- Wallpaper is divided into a variety of materials, buy as far as possible without the use of pvc synthetic wallpaper used in the home, because pvc environmental performance relative to the natural material of wood pulp wallpaper, fiber wallpaper. The fabric wallpaper is worse, especially those that smell the plastic wallpaper. Environmental protection is the primary condition for choosing a wallpaper, followed by color and price. In all kinds of wallpaper, consumers need to choose environmentally friendly, reliable wallpaper.

- Q: Upstairs noise how can we install sound insulation material can have effect?

- Ceiling paste extruded polystyrene board, and then hang fiberglass scraping crack mortar, and then do decoration, sound insulation according to polystyrene board thickness, can have effect.

- Q: Hi Y/A, I have to repair some old ugly seams that have been patched badly, painted over twice and are now cracking as well, you know, where rooms are divided at the ceiling? What's the best way to clean those up without knocking them out and doing it <right> over? I have one, fairly long one..5 ft.

- anytime you repair drywall you need tape i like fiberglass tape for repairs and durabond its harder and drys faster just make sure you get any lose off then patch it buy bedding the tape in the mud or drywall compond then let dry apply 2 more coats then sand prime and repaint use a bigger knife each coat to widen the coats and wipe it smooth not leaving a edge thats the sanding that will take place good luck

- Q: Drawing a candy shop, what should i put on the ceiling apart from lights??

- Ceiling fans come to mind first. You could color each fan a different color or you could color each fan to look like candy cane stripes. If you are going for an old fashion candy shop, draw ornate ceiling tiles, they are sharp!

- Q: How to install an extruded board for heat insulation?

- Install the extruded board: first squeeze the extruded board on the wall, and then with 2 meters on the wall to the pressure, and at the same time leveling, the professional bonding gypsum mortar or polymer mortar from 10 mm to 3 mm, Construction process: from bottom to top sticky, wrong seam, bonding area shall not be less than 30 ~ 50%.

- Q: I'm looking to move into a new apartment by the end of the month. It's in a good location, however the only down side is that the neighbors upstairs have kids and they run a day care during the day. Luckily I work and won't be home until 5:30 or so, but just by visiting the place today I could hear them walking upstairs and I'm sure that it's going to annoy me.I would like to know if anybody has any ideas on how to noise proof my ceiling for a reasonable price. Is there some kind of paint that effectively noise proofs walls and such, or would I have to wreck the ceiling and place fiberglass or something of the sort in order to ensure that I don't hear them walking or they don't hear me playing loud music and such.Any help is appreciated, thanks!

- If you are certain that you are going to be annoyed by the neighbors and will have to invest a lot of time and money in the apartment just to get it to an acceptable state, WHY MOVE IN THERE?

- Q: I had the roof replaced last summer, but havent had the energy to get up there and take down the ceiling tiles and the fiberglass insulation. I started removing it a section at a time a week ago, and wow! What a mess!. Gravel is falling down on my head and the insulation and tiles are dry now, but its still hard to pull them out. Should I be wearing a mask? Is there anything in the old dried out insulation and ceiling tiles that I should cover my nose? Its making a really big mess, so any suggestions will be helpful.

- No Brainer , YES,YES,YES. You might even put on ball cap.

- Q: wool /foil/fibtreglassim lost what would be the best as in cooler at summer and warmer in winter

- Fiberglass is the best. You can either go with batts or loose fill, which is blown in. 14 of loose fill gives you R-38, as does 13 of batts. Hope this helps.

- Q: Renovation of living room wall with steel bricks

- Do not have trouble, with the United States painted paint art paint can make you want any style and effect, both environmentally friendly and labor

- Q: My studio apartment doesn't have an attic. A lot of the installation videos and articles I read online are about installing foil insulation a couple inches below the roof and above the room's ceiling. Does it matter if I install it under the ceiling (that is, the foil barrier is visible to me when inside the apartment)?Aesthetics isn't an issue. I don't mind seeing the foil. I just want to know if I can still achieve the same results whether or not I install above the ceiling. Thanks!

- The foil would only radiate visible light back toward you, and fiberglass insulation ( or rigid polyisocyanurate panels covered with drywall) would create a barrier to keep the heat in your room. If just foil worked, you would assume no one would bother with installing 10 thick fiberglass to achieve an R-38 rating and spend thousands of dollars if a couple hundred of foil would do it.

Send your message to us

Fiberglass Drop Ceiling Tiles - Acoustic Fiberglass Ceiling, Well Quality, Concealed

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords