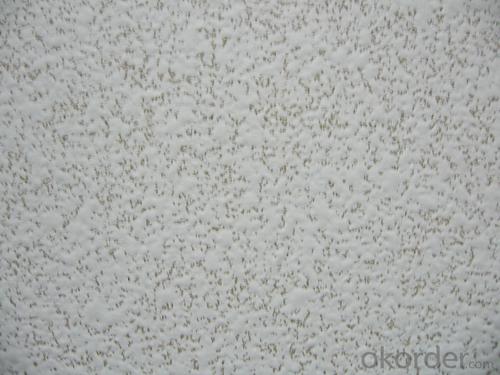

Fiberglass Porch Ceiling - Acoustic Fiberglass Ceiling 20mm Thickness Good Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Ceiling - concealed edge C

The tiles are manufactured from high density fiberglass wool.The visible face has a decorative fiberglass tissue and the back of the tile is covered with normal tissue.The four edges of the tile are sealed and have grooves. It can be jointed together without suspended system. The tiles will cover the suspension system after installation. They are are suitable for loe flap ceiling space and concrete-made, wooded-made or gymsum ceiling.

Installation method:

Use screw to fix the smooth roof. The tiles can be connected after making grooves on each two jointed edges.

Tiles are easy to trim and install

Both inches and metric grids are available

Main Characteristic:

Non-combustible

No sagging,wrapping or delaminating

Green building material

Excellent sound absorption

Application:

Halls,classrooms,offices,shopping centers.etc.

Acoustic fiberglass ceiling contains a better perfomance in tension strong, light weight, so it is easy to trim and install for interior decoration, with T-grids for suspension system or glue, nail or good material could come with fiberglass ceiling baord. Thus an excellent artical work need a high quality acoustic ceiling board, also high quality.

Energysaving is a trend for our 21' era, new product like fiberglass ceiling tile could in place of traditional products one day. Which depends on functional characters: little deflection of geometry dimention, no radiocative property, specific activity of 226Ra: Ira ≤1.0 and specific activity of 226 Ra 232 Th, 40 K: Ir ≤ 1.3. Both products and packages can be recycled.

- Q: What is the use of Mgcl?

- Relative molecular mass 95.21. Was colorless hexagonal crystal. Density 2.316-2.33 g / cm 3. Melting point 714 ℃. Boiling point 1412 ℃.

- Q: Magnesium oxide and magnesium chloride

- Magnesium chloride Uses: for the production of metal magnesium, disinfectant, frozen brine, ceramics, and used to fill the fabric, paper and so on. The solution is mixed with magnesium oxide, can become hard wear-resistant magnesia cement. Magnesium oxide is mainly used for the preparation of ceramic, enamel, refractory crucible and refractory bricks of raw materials. Also used as a polish, binder, coating and paper filler, chloroprene rubber and fluororubber accelerator and activator. And magnesium chloride and other solutions mixed, can be made of magnesium oxide water. Medicine for antacids and laxatives for gastric acid, stomach and duodenal ulcer disease. Raw materials used as catalysts and magnesium salts in the chemical industry. Also used for the production of glass, dyed meal, phenolic plastic and so on. Heavy-duty magnesia Milling industry for firing and grinding. The construction industry is used in the manufacture of artificial chemical flooring, artificial marble, heat shields and sound insulation panels. The plastic industry is used as a filler. It can also be used to produce other magnesium salts.

- Q: How to choose table tennis floor

- Butterfly racket in order to meet your requirements, at least 300 yuan, 150 yuan can not reach your request.

- Q: Interior designers should understand which decoration materials

- If you want to be the basic designer to all materials should be familiar with, some not commonly used materials are not too familiar with the words also have a better understanding.

- Q: I have a partially finished basement, hardwood floors above. What can I do soundproof the unfinished ceiling? I'm not planning on finishing, I want that area to serve as a hang out spot for the family and I don't want to worry about fiberglass dust.

- To sound proof you need to do two things, isolate and absorb. This means that the surface facing the basement should not be in direct contact with the floor above and some sort of material with adequate mass needs to be between to absorb the sound. It sounds like you don't want to go overboard with this project so I would suggest insulation batts and a dropped ceiling. Dow makes a 'safetouch' insulation that does not create dust and that you do not need to use a mask while installing (though I still would). There are newer styles of dropped ceilings out there now with a lower profile that use tracks that are relatively easy to install. I think one brand is called CeilingLink. This will look nice, block a lot of sound and allow access in case it is needed in the future. Best of luck, and maybe consider a radon gas detector.

- Q: What are the characteristics of the use of fiberglass ceilings?

- I have a voice, because my home is the Jiangsu Sanxian Architectural Acoustics System Co., Ltd. production of fiberglass ceiling

- Q: Can you play a sound absorbing effect with a grid ceiling?

- With a grille ceiling, sealed ceiling (or microporous, such as aluminum microplate, gypsum microplate), to maintain a certain internal space, the deeper the better the internal strength, the air filled with sound-absorbing cotton, Allow, fill about 20 centimeters. Do not fill up. Such as off the micro-porous ceilings, sound-absorbing cotton can be sealed with non-woven (anti-sound-absorbing cotton dust).

- Q: Write a writing for the future

- Look at some science fiction may help but do not look addicted

- Q: What is the best material for interior decoration

- Of course, is the choice of non-toxic harmless and environmentally friendly materials the best! For example, the choice of the original floor of the original solid wood flooring.

- Q: New home decoration is the choice of all-inclusive or half-pack good?

- Half pack is to save some money, all-inclusive to save trouble! Mainly to find a good point of the decoration company! Give you some material for reference!

Send your message to us

Fiberglass Porch Ceiling - Acoustic Fiberglass Ceiling 20mm Thickness Good Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords