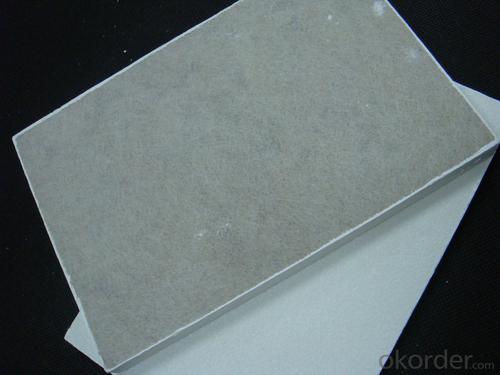

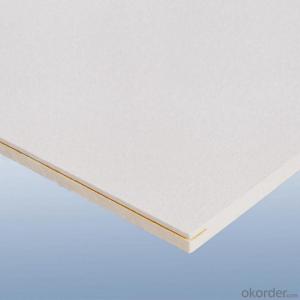

Fiberglass Oval Ceiling - Acoustic Fiberglass Ceiling Well Quality 12mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Ceiling

The tiles are manufactured from high density fiberglass wool.The visible face has a decorative fiberglass tissue and the back of the tile is covered with normal tissue.The four edges of the tile are sealed and have grooves. It can be jointed together without suspended system. The tiles will cover the suspension system after installation. They are are suitable for loe flap ceiling space and concrete-made, wooded-made or gymsum ceiling.

Installation method:

Use screw to fix the smooth roof. The tiles can be connected after making grooves on each two jointed edges.

Tiles are easy to trim and install

Both inches and metric grids are available

Main Characteristic:

Non-combustible

No sagging,wrapping or delaminating

Green building material

Excellent sound absorption

Application:

Halls,classrooms,offices,shopping centers.etc.

Acoustic fiberglass ceiling contains a better perfomance in tension strong, light weight, so it is easy to trim and install for interior decoration, with T-grids for suspension system or glue, nail or good material could come with fiberglass ceiling baord. Thus an excellent artical work need a high quality acoustic ceiling board, also high quality.

Energysaving is a trend for our 21' era, new product like fiberglass ceiling tile could in place of traditional products one day. Which depends on functional characters: little deflection of geometry dimention, no radiocative property, specific activity of 226Ra: Ira ≤1.0 and specific activity of 226 Ra 232 Th, 40 K: Ir ≤ 1.3. Both products and packages can be recycled.

- Q: I kinda left the sink on while i was taking a shower.. so when i got out my bathroom floor had water everywhere (about an inch of water)i mopped up the mess with towels but i forgot to wipe inside the cabinets (and that what caused the water to soak through according to my mom) now i'm being screamed at every. single. day.on the first floor if you look up, the ceiling pretty much dried up but theres 2 creases popping out. kind of like a loong 3-d v shape since the water soaked through and outlined the cabinets shape.and since my mom loves burdening me soo much, now my parents say that they lost 5 grand in our house's value T____Ti don't know if we're supposed to repair it, paint over it (though u can't rlly paint over it), or w/e.. does anyone know what i should do? don't tell me to call a repair man because my parents want to see their 'options' before they call themThanks.. :)

- Peel away the loose and damaged surface. Get a container of 60 min sheetrock mud, fiberglass mesh tape and a trowel. Tape over the seams making sure the tape is IN the ceiling surface, put several coats (thin) on the ceiling, and then try to match the texture if you can. Paint over entire ceiling. This is what a contractor will do.

- Q: Is anyone familiar enough with asbestos to know if this ceiling tile contains them:It is clearly damaged and need to be removed if it does. Thanks.

- No its a fiberglass tile with a decorative covering. Fiberglass is still an irritant though so wear gloves and a mask.

- Q: Ceiling for light steel keel face coated gypsum board coated with white latex paint.

- 1, hanging keel check whether the good discharge of sewage pipes and so on and whether it is located in the bathroom upstairs bathroom humid position, if you do first do a waterproof; 2, should be selected when the weather is relatively dry when the closure plate; 3, the latex paint should also be relatively dry, and the gypsum board itself can not be damp; 4, the tidal atmosphere of indoor space attention to dehumidification

- Q: We had our carpets removed a while ago and installed laminate flooring instead.As a result, the house is not as warm as it used to be.Will it help if I add R13 insulation in the basement ceiling ? Will it keep the living room floor (which is just above the basement) warmer ?On the same manner, will adding another layer of insulation to the attic help in the winter and summer as well ?As for the mositure barrier paper, if I understand correctly, it should be facing up both cases, right ?

- A vapor barrier always will go the heated side. But in you situation, just use unfaced insualtion in both applications. DO NOT use any plastic to cover anything. This will only trap moisture.

- Q: There are a lot of wires and tubing between the joists and I'm not sure if I'm supposed to work the insulation around them or just lay the stuff over it. Seems like if there was a problem with the water or electricity, finding the wires and such would become a problem with them tucked under the insulation. Any help would be greatly appreciated.

- i wouldnt insulate we have a finished basement and drop tile cealing and what ever the temp is up stairs thats what the basement will be (winter time). if you basement walls that are not inaulated thats what needs to get done.

- Q: The role of magnesium chloride?

- The use of magnesium chloride ????1, in the chemical industry is an important inorganic raw materials for the production of magnesium carbonate, magnesium hydroxide, magnesium oxide and other magnesium products, but also for the antifreeze and other raw materials. ????2, in the metallurgical industry for the production of metal magnesium, liquid chlorine and high purity magnesia and so on. ????3, in the building materials industry is the production of light building materials such as fiberglass, decorative panels, sanitary ware, ceilings, floor tiles, magnesium oxide cement, ventilation pipes, anti-theft covers, fire doors and windows, fire board, partition board, production of artificial marble High - rise building materials important raw materials. In the magnesite products can do high-quality magnesium tile, high-quality fire board, magnesium box, magnesium decoration plate, light wall panels, abrasive, stoves, fireworks and other additives. ????4, in other areas can do food additives, protein coagulant, snow melting agent, refrigerant, dust, refractories and so on. With the brine (magnesium chloride aqueous solution) point of the tofu than the stone point of the tofu, soft and delicious fresh ????5. Metallurgical industry: for the manufacture of refractory materials and puzzle arm of the adhesive, and is the manufacture of flux and smelting metal magnesium raw materials. ????6. Machinery industry: life, with lime soil can be made of mechanical crates, triangular mats and furniture, etc., is "soil material" good material. ????7. Transportation industry: for the road ice melting agent, ice fast, less corrosive to the vehicle, higher than the effect of sodium chloride. The ????8. Medicine: made of magnesium chloride "halogen dry" can be used for medicinal purposes. ????9. Agriculture: available for magnesium fertilizer, potassium and magnesium fertilizer and cotton defoliants.

- Q: I'm thinking of adding a ceiling to my porch to create an insulation space (the roof alone radiates a lot of direct heat in the summer; the porch otherwise is open) between it and the roof (corrugated fiberglass) but I'd like to still be able to see the roof as I've already painted the roof's interior and like how it contrasts with the supporting frame's color.I'm also looking to paint the exterior of the roof to better waterproof it (some leaks where previous owner screwed it in) and to better reflect light to further reduce heat. Any suggestion on paint or would it be better to just replace the roof entirely with better material? Thanks!

- There are many ways you could go. Yes, you can use the plexi to create insulation space. The best insulation is dead air. That is, air that cannot circulate and move around. The key to using it will be using something to seal it tight, a clear silicone caulk, perhaps. They make a special glue for it, you could make smaller areas to help keep air movement down with strips inside the ceiling area to form the pockets of air. Think bubblewrap, only solid. Probably caulk or glue on the joists is good enough. As for the exterior, fiberglass is extremely difficult to get paint to stick to, unless you use the gel coat stuff made for it. Maybe there is a good primer to make it take paints. If possible, paint it with the same stuff made for mobile home roofs, tho I don't know how well it will stick to fiberglass, it does fine on the metal roof of a mobile home. The stuff I'm talking about is available in only a few colors, white, silver, gray, and black. It's thick, like tar, but not tar. If you use the silver or white, it should help keep down the heat, after all, that's what it's designed for. It also has insulation and leak sealing properties. If you have a good cheap supply of the plexi, you could also put plexi over it for sealing, but before you do, you could use window tint on it, the kind that looks like a mirror on one side, and is dark on the other. put the mirror towards the sun. If you put your mind to it, there are probably many many ways to get done what you need to do. Maybe there's some way to use recycled materials.

- Q: Does the fiberglass ceiling do the ceiling?

- Long mineral wool ceiling to introduce advanced Japanese production technology, the use of European green standards testing, monitoring, the introduction of the production of European-style Italian light steel keel production system.

- Q: You would have chosen to join the huts?

- Wooden houses in Europe and the United States is very popular, especially in North America, wood structure building system since 1830 has dominated. Each year, more than 90% of the new 1.5 million to 2 million houses in North America use wooden structural systems. Which lasted for centuries, the wooden structure of the building with its a series of superior characteristics, so that residents living in North America enjoy the world's highest standards of housing.

- Q: Large area gypsum board light with no blockboard solid

- House interior wallboard, ceiling. All the panels are inside the gypsum board. Generally 12 mm thick, the surface is paper. There are very few glass fibers in the middle. It is fireproof moisture absorption sound insulation, is very good building materials. Used for decades to the present.

Send your message to us

Fiberglass Oval Ceiling - Acoustic Fiberglass Ceiling Well Quality 12mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords