200 300 Series Grade 2B Stainless Steel Sheet Manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

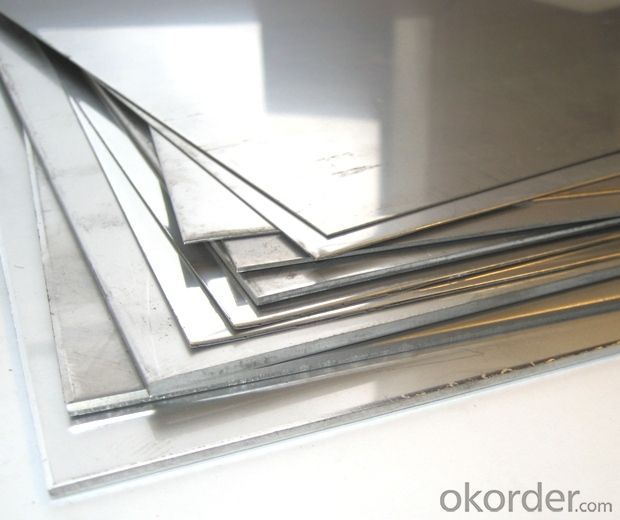

200 300 Series Grade 2B Stainless Steel Sheet Manufacturer

Packaging Details:Wooden pallets,water proof paper-20'GP or 40'GP for stainless steel sheet.

Delivery Detail:within 5-7 days after receiving the deposit

1. Specifications about stainless steel sheet

Commodity | Professional 430 201 202 304 304l 316 316l 321 310s 309s 904l stainless steel sheet |

Grade | 201,202,304,304L,316,316L,310S,309S,321,301,310,410,420,430,904L |

Brand | TISCO ,BAOSTEEL,POSCO,JISCO,LISCO |

Certification | SGS,BV,IQI,TUV,ISO,etc |

Thickness | 0.2mm-150mm |

Width | 1000,1219,1250,1500mm, or as your requirements |

Length | 2000,2438,2500,3000,6000mm, or as your requirements |

Surface | No.1, 2B, BA, 8K Mirror, Hairline,satin, Embossed,brush,No.4,HL,matt,pvc film,laser film. |

Standard | ASTM,AISI,SUS,JIS,EN,DIN,GB, ASME,etc |

Delivery time | 5-7 days after confirming the order |

MOQ | 1 Ton |

Advantages | Showing the splendor of your quality, wearresistant as well , strong corrosion resistance and decorative effect, durable and beautiful in good taste. |

2.Production Flow about stainless steel sheet

Raw materials are sending to hot rolling units for rolling into different sizes

Hot rolled material is annealing in cold; rolled annealing furnace and pickling in acid.

All mill rolls are grinded on precision grinding machine with proper chamfering after first shiftoperation.

All sheets are pickled in different tanks and dried on brush roll machine before dispatched.

These sheets are again annealing and are sent to straighten machine for straightening.

Inspections are done at various stages. Keep proper control overall internal process via rolling,annealin and pickling by our experienced staff.

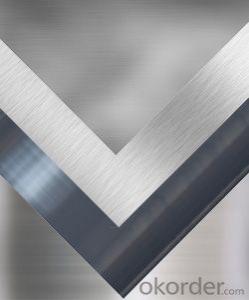

3.Surface--stainless steel sheet

| Surface Finish | Definition | Application |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA/8K mirror | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

| Hairline | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

- Q: What are stainless steel sheets made of?

- Stainless steel sheets derive from a steel alloy comprising at least 10.5% chromium. By introducing chromium, a passive film forms on the steel's surface, rendering it resistant to corrosion and staining. Besides chromium, stainless steel sheets might incorporate additional elements like nickel, molybdenum, and nitrogen, heightening their mechanical properties and corrosion resistance. The precise composition of stainless steel sheets can fluctuate based on the intended properties and applications.

- Q: Can stainless steel sheets be cold rolled?

- Yes, stainless steel sheets can be cold rolled. Cold rolling is a process in which stainless steel sheets are passed through a series of rollers at room temperature to reduce their thickness and improve their surface finish. This process helps in enhancing the strength and hardness of the stainless steel sheets while maintaining their corrosion resistance properties.

- Q: Are stainless steel sheets suitable for elevator wall panels?

- Yes, stainless steel sheets are suitable for elevator wall panels. Stainless steel is a popular material choice for elevator wall panels due to its durability, corrosion resistance, and aesthetic appeal. Elevators are high-traffic areas that require a material that can withstand constant use and potential impact. Stainless steel sheets are robust and can withstand wear and tear. Additionally, stainless steel is highly resistant to corrosion, making it suitable for environments with high humidity or exposure to chemicals. Furthermore, stainless steel has a sleek and modern appearance that adds a touch of elegance to the elevator interior. Overall, stainless steel sheets are a reliable and aesthetically pleasing choice for elevator wall panels.

- Q: What is the yield strength of stainless steel sheets?

- The yield strength of stainless steel sheets can vary based on the specific grade and thickness of the sheets. Typically, stainless steel sheets exhibit a yield strength between 30,000 and 100,000 psi. However, it is worth noting that different grades of stainless steel possess varying yield strengths. For instance, austenitic stainless steel grades such as 304 and 316 typically exhibit higher yield strengths in comparison to ferritic or martensitic stainless steel grades. Furthermore, the yield strength of stainless steel sheets can also be influenced by their thickness, with thicker sheets generally exhibiting higher yield strengths. Ultimately, it is crucial to refer to the specific grade and thickness of the stainless steel sheets in order to accurately determine their yield strength.

- Q: What specifications do stainless steel plates have?

- This is not specified. Do you want to make 201 or 304?. You can measure the size of the bag you want. Double fold (usually 10MM), such as length, width, and thickness of the package. Go and ask someone to do it for you. If fitted, use a glass or spot weld.

- Q: What is the difference between stainless steel sheets and plates?

- The main difference between stainless steel sheets and plates lies in their thickness. Stainless steel sheets are typically thinner and have a uniform thickness throughout, whereas stainless steel plates are thicker and have varying thicknesses depending on the specific application. Plates are commonly used for structural or heavy-duty purposes, while sheets are more commonly used for decorative or lightweight applications.

- Q: What is the maximum operating temperature for stainless steel sheets?

- The maximum operating temperature for stainless steel sheets typically ranges from 1500°F to 1650°F (815°C to 900°C), depending on the grade of stainless steel.

- Q: What are stainless steel sheets?

- Stainless steel sheets are flat metal plates made from an alloy of iron, chromium, and other elements that prevent corrosion and rusting. They are commonly used in various industries such as construction, automotive, and manufacturing, due to their durability, strength, and resistance to staining and oxidation.

- Q: How do I determine the hardness of stainless steel sheets?

- To determine the hardness of stainless steel sheets, there are a few methods you can use. One common method is the Rockwell hardness test, which measures the depth of penetration of an indenter into the material. The Rockwell scale has different scales depending on the material, so you will need to use the appropriate scale for stainless steel. To perform the Rockwell hardness test, you will need a Rockwell hardness tester and a diamond or tungsten carbide indenter. Start by placing the stainless steel sheet on a flat, stable surface. Then, position the indenter on the surface of the sheet and apply a minor load. Once the minor load is applied, proceed to apply the major load until it reaches its maximum value. Once the load has been applied and released, the hardness value will be displayed on the Rockwell hardness tester's dial or digital display. This value corresponds to a specific hardness scale, such as HRC for stainless steel. It is important to note that the Rockwell hardness test provides a relative measurement of hardness and does not necessarily reflect the material's physical properties. Additionally, the hardness of stainless steel can vary depending on factors such as the alloy composition, heat treatment, and manufacturing process. Therefore, it is recommended to consult the material's specifications or conduct additional tests to obtain more accurate and comprehensive information about the stainless steel sheet's hardness.

- Q: Are stainless steel sheets suitable for high-traffic areas?

- Indeed, high-traffic areas can benefit from the use of stainless steel sheets. Renowned for their durability, strength, and resistance to corrosion, stainless steel proves to be an outstanding option for spaces frequented by many individuals. It possesses the ability to endure continuous usage and mistreatment, encompassing scratches, dents, and impacts, all while maintaining its structural integrity. Moreover, stainless steel sheets present themselves as effortless to clean and maintain, rendering them an optimal choice for regions necessitating frequent cleaning and disinfection. In summary, stainless steel sheets offer a dependable and enduring solution for high-traffic areas.

Send your message to us

200 300 Series Grade 2B Stainless Steel Sheet Manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords