Stainless Steel Sheets 2B BA finish 201 304 316 430

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Stainless Steel Sheets 2B BA finish 201 304 316 430

Product name | stainless steel sheet 2b ba finish 201 304 316 430 |

Specification | Thickness: Cold rolled: 0.3-3mm, Hot Rolled: 3-120mm Customized sizes are accepted |

Standard | ASME, ASTM, EN, BS, GB, DIN, JIS, etc |

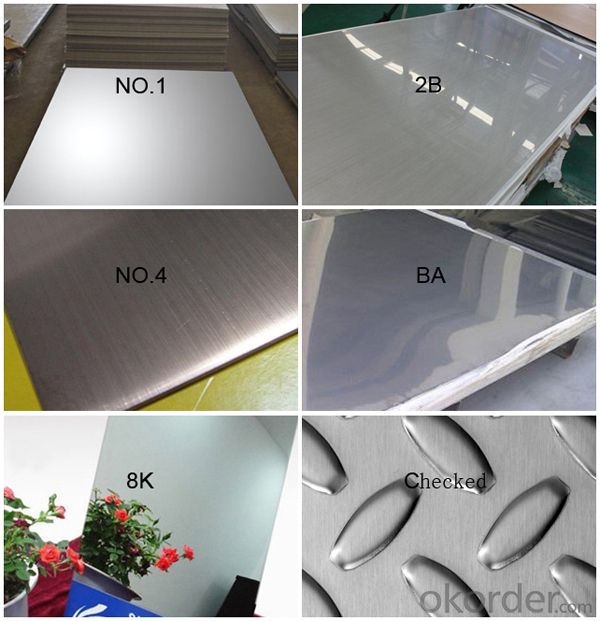

Finish | NO.1, NO.4, 2B, BA, HL, 8K, Mirror finish and so on |

Material | 201, 202, 304, 304L, 310S, 316, 316L, 410, 420, 430, 441, 800H, 904L |

Technical treatment | Cold Rolled, Hot Rolled |

Port of Loading | Tianjin, Shanghai, Ningbo, Guangzhou |

Terms of Delivery | FOB, CFR, CIF, CNF |

Terms of Payment | L/C, T/T (30% deposit) |

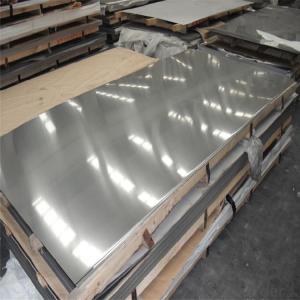

Packing | Standard export sea-worthy packing |

Delivery time | Within 7-15 days after receive 30% deposit or as your requirement |

Finished Products

Surface Finished | Characteristics | Application |

BA | Bright heat treatment after cold rolling. | Kitchen utensil, Kitchen ware, Architectural purpose. |

2B | Finished by heat treatment, pickling after cold rolling, followed by skin pass line to more brighter and smooth surface. | General application medical instruments, Tableware. |

NO.1 | Finished by hot-rolling, annealing and pickling, characterized by white pickled surface. | Chemical industry equipment, Industrial tanks. |

8K(mirror) | A mirror-like reflective surface by polishing with finer abrasives over 800 mesh. | Refletor, Mirror, Interior- Exterior decoration for building. |

Hair Line | Finished by continuous linear polishing. | Architecture industries, Escalators, Kitchen ware, Vehicles. |

Packaging & Shipping

Packaging:All products are packaged according to the Standard export packing.In order to prevent friction damage and water erosion and so on.

Shipping: Ocean transportation,land transportation or air transportation.

- Q: Can stainless steel sheets be used for solar water heaters?

- Yes, stainless steel sheets can be used for solar water heaters. Stainless steel is a durable and corrosion-resistant material, making it suitable for withstanding the harsh conditions of solar water heating systems. It ensures longevity and reliable performance in capturing and transferring solar energy to heat water efficiently.

- Q: What is the hardness of stainless steel sheets?

- The hardness of stainless steel sheets can vary depending on the specific grade and manufacturing process. Generally, stainless steel sheets are known for their high hardness and strength. The most common grades used in industrial applications, such as 304 and 316, have a hardness range of 70-90 HRB (Rockwell hardness B scale) or 150-200 HV (Vickers hardness). However, there are also specialized stainless steel alloys that can have even higher hardness values, such as precipitation-hardened grades like 17-4 PH, which can reach hardness levels of 30-40 HRC (Rockwell hardness C scale). To determine the exact hardness of a specific stainless steel sheet, it is necessary to consult the manufacturer's specifications or perform hardness testing using appropriate methods and equipment.

- Q: How about stainless steel grades?

- 304 - that is, 18/8 stainless steel. GB is 0Cr18Ni9. 309 - better temperature resistance than 304. 316 - after 304, second of the most widely used steel grades are used mainly in the food, pharmaceutical and pharmaceutical industries, and molybdenum is added to obtain a special corrosion resistant structure. Because of its better resistance to chloride corrosion than 304, it is also used as "ship steel". SS316 is usually used in nuclear fuel recovery devices. Grade 18/10 stainless steel usually meets this application level. [

- Q: What is the thickness range of stainless steel sheets?

- The thickness range of stainless steel sheets can vary depending on the specific grade and application. However, typically stainless steel sheets are available in thicknesses ranging from 0.4mm to 6mm. Additionally, there are specialized stainless steel sheets available in thinner gauges, such as foil sheets that can be as thin as 0.02mm. On the other hand, for heavy-duty applications, stainless steel sheets can be as thick as 50mm or more. Ultimately, the desired thickness of a stainless steel sheet will depend on the intended use, structural requirements, and aesthetic preferences.

- Q: How do you prevent galvanic corrosion when using stainless steel sheets?

- One effective method to prevent galvanic corrosion when using stainless steel sheets is to ensure they are not in direct contact with dissimilar metals. This can be achieved by using insulating materials or coatings, such as rubber gaskets or paint, between the stainless steel sheets and other metals. Additionally, regular maintenance and cleaning of the stainless steel surfaces can help prevent the accumulation of corrosive substances that could lead to galvanic corrosion.

- Q: What is the difference between stainless steel sheets and stainless steel plates?

- The main difference between stainless steel sheets and stainless steel plates lies in their thickness. Stainless steel sheets are typically thinner, with a thickness ranging from 0.4mm to 6mm, while stainless steel plates are thicker, with a thickness starting from 3mm and going up to several inches. Additionally, stainless steel plates are often used for structural purposes or heavy-duty applications, while stainless steel sheets are commonly used for decorative purposes, cladding, or smaller projects.

- Q: What are the applications of stainless steel sheets in the automotive industry?

- Stainless steel sheets are widely used in the automotive industry due to their numerous beneficial properties. These sheets find applications in various components and parts of automobiles, contributing to the overall performance, durability, and aesthetics of vehicles. One of the key applications of stainless steel sheets in the automotive industry is in the production of exhaust systems. Stainless steel is highly resistant to corrosion and heat, making it an ideal material for exhaust pipes. These sheets can withstand the high temperatures generated by the engine, ensuring longevity and reliability of the exhaust system. Additionally, stainless steel sheets are used in the manufacturing of automotive body panels. They provide excellent strength and rigidity, allowing for the production of lightweight yet sturdy body parts. Stainless steel's resistance to corrosion is also advantageous, as it ensures that the body panels do not degrade over time, even in harsh weather conditions. Furthermore, stainless steel sheets are employed in the production of fuel tanks and other fluid storage components. Stainless steel's corrosion resistance and ability to withstand high pressure make it a suitable material for these applications. The use of stainless steel in fuel tanks ensures that they remain leak-free and durable, leading to enhanced safety and longevity. Moreover, stainless steel sheets are utilized in the production of various interior and exterior trim parts. These include decorative elements such as grilles, trims, and accents, which enhance the aesthetics of the vehicle. Stainless steel's ability to be polished and finished to a high shine adds a touch of elegance and sophistication to the car's design. In summary, stainless steel sheets have numerous applications in the automotive industry. They are used in exhaust systems, body panels, fuel tanks, and trim parts, among others. The exceptional properties of stainless steel, such as corrosion resistance, heat resistance, and strength, contribute to the overall performance, durability, and aesthetics of automobiles.

- Q: What glue does the board and the stainless steel stick to?

- Application of epoxy resin adhesive is widely used in bonding of various metals and alloys, ceramics, glass, wood, cardboard, plastic, concrete, stone, bamboo and other non-metal materials, or bonding of metal and non-metallic materials. For untreated polyethylene, polypropylene, PTFE, polystyrene, PVC and other plastic without adhesion, for rubber, leather, fabric and other soft material adhesive ability is also poor.

- Q: How do you prevent scratches or dents on stainless steel sheets?

- There are several measures that can be taken to avoid scratches or dents on stainless steel sheets: 1. Exercise caution when handling: Take care not to drop or drag stainless steel sheets against rough surfaces. It is advisable to wear gloves or protective gear to minimize the risk of scratches caused by sharp objects or tools. 2. Opt for gentle cleaning materials: To prevent scratches when cleaning, use soft cloths or non-abrasive sponges. Avoid steel wool or harsh cleaning agents that can harm the surface. Also, make sure to wipe in the direction of the grain to preserve the stainless steel's appearance. 3. Apply protective films or sheets: Adding a protective film or sheet to the stainless steel surface can provide an extra layer of defense against scratches or dents. These films are typically adhesive and can be easily removed once the stainless steel sheets are installed. 4. Store correctly: Store stainless steel sheets in a clean and dry environment to prevent scratches or dents caused by contact with other objects. Avoid stacking sheets directly on top of each other without any protective barrier in between. 5. Invest in edge protectors: Stainless steel sheets are often susceptible to dents or scratches on their edges. Using edge protectors or corner guards can help prevent damage during handling, transportation, or storage. By adhering to these preventive measures, the likelihood of scratches or dents on stainless steel sheets can be significantly reduced. This will ensure their durability and preserve their flawless appearance.

- Q: What is the weight of stainless steel sheets?

- The weight of stainless steel sheets can vary depending on their thickness and dimensions. Generally, stainless steel sheets weigh between 1.5 to 3 pounds per square foot.

Send your message to us

Stainless Steel Sheets 2B BA finish 201 304 316 430

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords