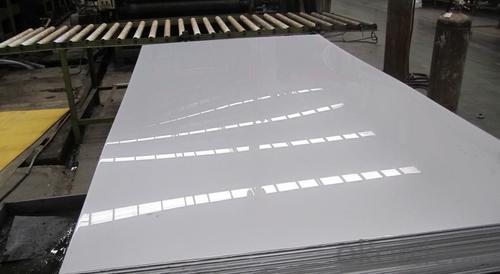

Stainless Steel sheet and Plate in deap discount

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of stainless steel

304 stainless Steel Plate

stainless steel plate,steel sheet,steel plate

Standard: ASTM,GB,DIN,JIS,ISO,EN,etc.

TISCO stainless Steel Plate 304/NO.1 finished

stainless steel plate,steel sheet,steel plate

Standard: ASTM,GB,DIN,JIS,ISO,EN,etc.

Delivery short and low cost advantage.

Description of stainless steel:

stainless steel plate,hot rolled stainless steel plate,cold rolled stainless steel plate,stainless steel sheet,steel sheet,sheet

Material of stainless steel:

304,304L,309S,310S,316,316L,316Ti,317L,317L,321,347H,409,409L,410S,420,430,201,202,etc.

Thickness of stainless steel:

From 0.3mm to 100mm

Width of stainless steel:

1000mm,1219mm,1250mm,1500mm,1800mm,2200mm,2500mm or as your requirement

Length of stainless steel:

2000mm,2438mm,2500mm,6000mm,6096mm or as your requirement

Application of stainless steel:

Stainless steel plate applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. Our company has cooperative relation between the domestic agents. Stainless steel plate can be made accordingto the customers requirements. Fasten delivery. Quality assured.Welcome to order more.

Contacts

If you have any question,please feel free to contact us.

- Q: What is the width of the carbon steel coil and the width of the stainless steel coil, one is 1250, and the other is 1219?

- A continuous rolling mill is put in billions of dollars, but this is the rolling mill, and there are many gold furnaces. But the technical content of carbon steel with stainless steel is different, our country in more than 10 years ago the ability of continuous rolling of stainless steel is not high, equipment are imported, the stainless steel mill is dominated by 1219-1300, but also the development of national wide stainless steel 1500-2050, but the price is expensive at least thousands of dollars a ton, after all put the equipment to recover the cost, and the number of business orders is not much, it is difficult to find a spot on the market. Carbon steel countries have developed for many years, technology and equipment are mature, so the market has 1250 as production standards.

- Q: How do you prevent intergranular corrosion on stainless steel sheets?

- Intergranular corrosion, which causes structural damage and reduced strength, occurs along the grain boundaries of stainless steel. To prevent this corrosion on stainless steel sheets, several steps can be taken: 1. Material Selection: To prevent intergranular corrosion, it is crucial to select the appropriate grade of stainless steel. Grades like 304L or 316L, which have low carbon content, are less susceptible to this type of corrosion due to their reduced sensitivity to sensitization. 2. Heat Treatment: One can heat treat stainless steel sheets to eliminate carbide precipitation, a common cause of intergranular corrosion. This process, known as solution annealing or sensitization heat treatment, involves heating the material to a specific temperature range and rapidly cooling it. This treatment ensures the formation of a consistent and corrosion-resistant microstructure. 3. Passivation: Passivation is a chemical process that removes contaminants and forms a protective oxide layer on the surface of stainless steel sheets. This layer acts as a barrier against corrosion and prevents intergranular attack. Typically, nitric acid or citric acid solutions are used for passivation. 4. Welding Techniques: Proper welding techniques should be employed when welding stainless steel sheets to minimize the risk of intergranular corrosion. This includes using low heat input, preventing excessive heat build-up, and using filler materials with low carbon content to prevent sensitization. 5. Avoiding Contamination: It is essential to protect stainless steel sheets from contamination by other metals, particularly those with higher galvanic potentials. Contact with carbon steel, for instance, can lead to galvanic corrosion and promote intergranular attack. Therefore, it is important to store and fabricate stainless steel sheets separately from other metals. 6. Regular Cleaning and Maintenance: Regularly cleaning and maintaining stainless steel sheets is vital to prevent the accumulation of corrosive substances or contaminants on the surface. Non-abrasive cleaners and proper cleaning methods should be used to avoid scratching the stainless steel, as scratches can create sites for corrosion initiation. By implementing these preventive measures, one can significantly reduce intergranular corrosion, ensuring the durability and performance of stainless steel sheets.

- Q: What are the color options for stainless steel sheets?

- Stainless steel sheets generally come in a variety of color options, depending on the specific type of finish applied to the surface. The most common color options for stainless steel sheets include silver, which is the natural color of stainless steel, as well as black, gold, bronze, and copper. These colors are achieved through processes such as powder coating, PVD coating, or chemical treatments, which create a thin layer on the surface of the stainless steel sheet. The color options allow for greater versatility in design and can be chosen to complement different aesthetics and applications.

- Q: Are stainless steel sheets available in different finishes?

- Indeed, there are various finishes in which stainless steel sheets are available. Stainless steel is a highly adaptable substance that can be finished in diverse manners for distinct visual and textural effects. Among the frequently used finishes are brushed, mirror, satin, and textured finishes. Each finish possesses its own distinctive aesthetic charm and can be selected according to the desired appearance and particular application demands. Moreover, the chosen finish can also influence the resistance of the stainless steel sheets against corrosion, staining, and scratching. Consequently, manufacturers provide an array of finishes to accommodate different customer preferences and specific project requirements.

- Q: What's the difference between stainless steel 302 and 304?

- Plate type heat exchanger, corrugated pipe, household appliances (1, 2 kinds of tableware, kitchen cabinet, indoor pipeline, water heater, boiler, bath), auto parts (windshield wiper, muffler, mold), medical appliances, building materials, chemical, food industry, agriculture, marine parts, millet mobile phone etc.. 304 stainless steel is a nationally recognized food grade stainless steel.

- Q: Are stainless steel sheets suitable for outdoor furniture?

- Stainless steel sheets are indeed a fantastic option for outdoor furniture. Renowned for their outstanding durability and ability to resist corrosion, stainless steel is the perfect material to withstand the harsh effects of the outdoors, including rain, sunlight, and temperature fluctuations. Moreover, cleaning and maintaining stainless steel sheets is a breeze, as they require minimal effort to retain their pristine appearance. Furthermore, stainless steel possesses a sleek and contemporary look that can enhance the overall aesthetic appeal of outdoor furniture. In summary, stainless steel sheets provide the impeccable blend of strength, longevity, and visual charm, establishing them as an excellent selection for outdoor furniture.

- Q: Can stainless steel sheets be used for restaurant equipment?

- Certainly! Restaurant equipment can indeed utilize stainless steel sheets. Stainless steel is a highly favored option for restaurant equipment owing to its multitude of advantages. Its durability, resistance to corrosion, and ease of cleaning all contribute to its popularity. By employing stainless steel sheets, restaurant equipment can be crafted into diverse forms and dimensions, fulfilling the particular needs of countertops, sinks, tables, shelves, and food preparation surfaces. Moreover, stainless steel is an exceptionally hygienic substance that does not interact with food or taint it, rendering it perfect for deployment in restaurant environments where cleanliness and food safety are of utmost importance.

- Q: Can stainless steel sheets be used for magnetic shielding?

- Yes, stainless steel sheets can be used for magnetic shielding to some extent. While stainless steel is not inherently magnetic, it does have some magnetic properties. Stainless steel alloys contain iron, a magnetic material, which allows them to exhibit weak magnetic characteristics. However, the magnetic shielding effectiveness of stainless steel sheets is limited compared to other materials specifically designed for magnetic shielding, such as mu-metal or nickel-iron alloys. These materials have a higher permeability, meaning they can redirect and absorb magnetic fields more effectively than stainless steel. Nonetheless, stainless steel sheets can still provide some level of magnetic shielding, especially in lower intensity magnetic fields. They can help reduce the transmission of magnetic fields from one area to another, which might be useful in certain applications. However, for high-intensity or sensitive magnetic shielding requirements, it is recommended to use specialized magnetic shielding materials for optimum effectiveness.

- Q: Can stainless steel sheets be formed into complex shapes?

- Yes, stainless steel sheets can be formed into complex shapes through various processes such as bending, rolling, and stamping.

- Q: Are stainless steel sheets resistant to hydrogen embrittlement?

- Yes, stainless steel sheets are generally resistant to hydrogen embrittlement. Hydrogen embrittlement is a phenomenon that occurs when hydrogen atoms diffuse into the metal structure, causing it to become brittle and prone to cracking. However, stainless steel has a high resistance to hydrogen embrittlement due to its unique composition and microstructure. The presence of chromium in stainless steel forms a protective oxide layer on the surface, which acts as a barrier to prevent hydrogen diffusion into the metal. Additionally, stainless steel sheets are often alloyed with other elements such as nickel and molybdenum, which further enhance their resistance to hydrogen embrittlement. However, it is important to note that certain conditions, such as exposure to high temperatures or high levels of hydrogen, can still potentially lead to hydrogen embrittlement in stainless steel. Therefore, it is crucial to consider the specific application and operating conditions when determining the suitability of stainless steel sheets in relation to hydrogen embrittlement.

Send your message to us

Stainless Steel sheet and Plate in deap discount

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords